没有合适的资源?快使用搜索试试~ 我知道了~

资源推荐

资源详情

资源评论

INCH-POUND

MIL-PRF-48656C

w/AMENDMENT 1

16 February 2023

SUPERSEDING

MIL-PRF-48656C

09 December 2021

PERFORMANCE SPECIFICATION

CARTRIDGES, SHOTSHELL

This specification is approved for use by all Departments and Agencies of the Department of

Defense within the distribution limitations noted at the bottom of the page.

1. SCOPE

1.1 Scope. This specification covers shotshell cartridges for use in military shotgun

weapons (see 6.1).

1.2 Classification. Items covered by this specification are as follows:

Type I – Combat / Riot or Military Police Applications (12 Gauge No. 00 Buckshot).

Type II - Training and Marksmanship Applications (12 Gauge No. 7 ½ Shot & No. 9

Shot).

Comments, suggestions, or questions on this document should be addressed to:

U.S. Army DEVCOM AC, ATTN: FCDD-ACE-QSA, Picatinny Arsenal, New Jersey 07806-

5000 or e-mailed to usarmy.pica.devcom-ac.list.ardec.list.ardec-stdzn-branch@army.mil.

Since contact information can change, you may want to verify the currency of this information

using ASSIST Online database at https://assist.dla.mil.

AMSC N/A FSC 1305

DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited.

Source: https://assist.dla.mil -- Downloaded: 2023-04-14T17:05Z

Check the source to verify that this is the current version before use.

MIL-PRF-48656C

w/AMENDMENT 1

2

2. APPLICABLE DOCUMENTS

2.1 General. The documents listed in this section are referenced in sections 3 and 4 of this

specification. This section does not include documents cited in other sections of this specification

or documents that are recommended for additional information or examples. While every effort

has been made to ensure the completeness of this list, document users are cautioned they must

meet all requirements as cited in sections 3 and 4 of this specification, whether or not they are

listed.

2.2 Government documents.

2.2.1 Specifications, standards, and handbooks. The following specifications, standards,

and handbooks form a part of this document to the extent specified herein. Unless otherwise

specified, the issues of these documents are those cited in the solicitation or contract.

DEPARTMENT OF DEFENSE SPECIFICATIONS

MIL-PRF-372 – Cleaning Compound, Solvent (For Bore of Weapons)

MIL-PRF-680 – Degreasing Solvent

MIL-PRF-14107 – Lubricating Oil, Weapons, Low Temperature

MIL-PRF-46000 – Lubricant, Semi-Fluid (Automatic Weapons)

MIL-PRF-63460 – Cleaner, Lubricant, and Preservative for Weapons and

Weapons Systems

DEPARTMENT OF DEFENSE STANDARDS

DOD-STD-2101 – Classification of Characteristics

MIL-STD-286 – Propellants, Solid: Sampling, Examination & Testing

MIL-STD-636 – Visual Standards for Small Arms Ammunition through

Caliber .50

MIL-STD-810 – Environmental Engineering Considerations & Laboratory

Tests

MIL-STD-1168 – Ammunition Lot Numbering and Ammunition Data Card

MIL-STD-1916 – DOD Preferred Methods for Acceptance of Products

(Copies of these documents are available online at https://quicksearch.dla.mil/.)

2.2.2 Other Government documents, drawings, and publications. The following other

Government documents, drawings, and publications form a part of this document to the extent

specified herein. Unless otherwise specified, the issues of these documents are those cited in the

solicitation or contract.

Source: https://assist.dla.mil -- Downloaded: 2023-04-14T17:05Z

Check the source to verify that this is the current version before use.

MIL-PRF-48656C

w/AMENDMENT 1

3

DEPARTMENT OF DEFENSE TECHNICAL BULLETIN

TB 700-2 – Department of Defense Ammunition and Explosives

Hazard Classification Procedures

(This document is available online at https://www.logsa.army.mil.)

U.S. ARMY COMBAT CAPABILITIES DEVELOPMENT COMMAND

ARMAMENTS CENTER (DEVCOM AC) DRAWINGS

7553347 – Box, Wirebound Boxes, Ammunition, M2A2

9390438 – Cartridge, 12 Gauge Shotshell, No. 00 Buckshot

9390439 – Cartridge, 12 Gauge Shotshell, No. 7 ½ Shot

9390440 – Cartridge, 12 Gauge Shotshell, No. 9 Shot

9396197 – Packing and Marking for M2A2 Ammo Box for

Cartridges, Shotshell

9396206 – Packing and Marking for Wirebound Box Assembly for

Cartridges, Small Caliber

12551623 – Cartridges, Loose Carton Pack – 12 Ga Shotshell,

No. 00 Buckshot

12551625 – Cartridges, Commercial Pack, 12 Ga Shotshell, No 7½ Shot

12551626 – Cartridges, Commercial Pack, 12 Ga Shotshell, No 9 Shot

13032542 – Box, Ammunition, M2A2 Assembly

(Copies of these drawings are available by email usarmy.pica.devcom-ac.list.drawing-request-

help-desk@army.mil.)

NAVAL SURFACE WARFARE CENTER INSTRUCTIONS

NAVSEAINST 8020.19 – Electrostatic Discharge Safety Program For Ordnance

(Copies of NAVSEA instructions are available online at: https://www.navsea.navy.mil.)

US ARMY TEST & EVALUATION COMMAND

ITOP 1-2-601 – Internal Test Operations Procedure FR/GE/UK/US

Laboratory Vibration Schedules

ITOP 4-2-601 – Drop Tests for Munitions

ITOP 4-2-602 – Rough Handling Tests TOP 1-2-608 Sound Level

Measurements

TOP 3-2-609 – Chemical Compatibility of Nonmetallic Materials Used in

Small Arms Systems

(Copies of these documents may be requested from the US Army Test and Evaluation

Command, online at https://www.atec.army.mil/publications/topsindex.aspx.)

Source: https://assist.dla.mil -- Downloaded: 2023-04-14T17:05Z

Check the source to verify that this is the current version before use.

MIL-PRF-48656C

w/AMENDMENT 1

4

2.3 Non-Government publications. The following documents form a part of this

document to the extent specified herein. Unless otherwise specified, the issues of these

documents are those cited in the solicitation or contract.

SPORTING ARMS & AMMUNITION MANUFACTURER’S INSTITUTE

SAAMI – Technical Committee Manual Vol. IV Shotshell

(Copies of SAAMI manuals are available at https://saami.org.)

AMERICAN NATIONAL STANDARDS INSTITUTE

ANSI/SAAMI Z299.2 – Voluntary Industry Performance Standards for

Pressure and Velocity of Shotshell Ammunition for

the Use of Commercial Manufacturers

(Copies of ANSI Standards are available at https://saami.org/technical-information/ansi-saami-

standards.)

2.4 Order of precedence. Unless otherwise noted herein or in the contract, in the event of

conflict between the text of this document and the references cited herein, the text of this

document takes precedence. Nothing in this document, however, supersedes applicable laws and

regulations unless a specific exemption has been obtained.

3. REQUIREMENTS

3.1 Design verification test. When specified (see 6.2), a sample of the shotshell cartridges

shall be subjected to design verification tests (DVT) in accordance with 4.1 and Table III.

Requirements that are established during DVT will be the baseline for first article and

conformance inspections.

3.1.1 Key characteristics. The key characteristics of the design that are deemed essential

to meet requirements of this specification shall be identified and variability limits or baselines

shall be established during design verification. The variability of key characteristics for the

cartridges submitted for first article and lot acceptance shall conform to the baseline established

for them during design verification (see 6.8).

3.1.2 Classification of characteristics. Defects inherent to the cartridge design that are not

already listed in Table VI shall be identified during design verification and shall be classified as

either a minor, major, or critical defect in accordance with DOD-STD-2101.

3.2 First article. When specified (see 6.2), a sample of the shotshell cartridges shall be

subjected to first article inspection in accordance with 4.2.

3.3 Conformance inspection. When specified (see 6.2), a sample of the shotshell

cartridges shall be subjected to conformance inspection in accordance with section 4.3.

Source: https://assist.dla.mil -- Downloaded: 2023-04-14T17:05Z

Check the source to verify that this is the current version before use.

MIL-PRF-48656C

w/AMENDMENT 1

5

3.4 Cartridge. The cartridge shall comply with all requirements specified on Drawing

9390438, 9390439 or 9390440 and ANSI/SAAMI Z299.2.

3.5 Operating requirements.

3.5.1 Primed case sensitivity. The primer sensitivity shall be determined by dropping a

steel ball onto a simulated firing pin. If one or more cartridge primers fail, a sensitivity rundown

test shall be conducted in accordance with 4.5.1.

3.5.1.1 Primer initiation. The energy imparted by a steel ball weighing 1.94 ± 0.02 ounces

falling 12 inches onto a simulated firing pin shall cause initiation of the primer.

3.5.1.2 Primer insensitivity. The energy imparted by a steel ball weighing 1.94 ± 0.02

ounces falling 2 inches onto a simulated firing pin shall not cause initiation of the primer.

3.5.2 Velocity. At a point 3.0 ± 0.5 feet directly in front of the muzzle of a 30.0 ± 0.1

inch test barrel, the mean velocity and the maximum standard deviation from the mean velocity

shall be as shown in Table I.

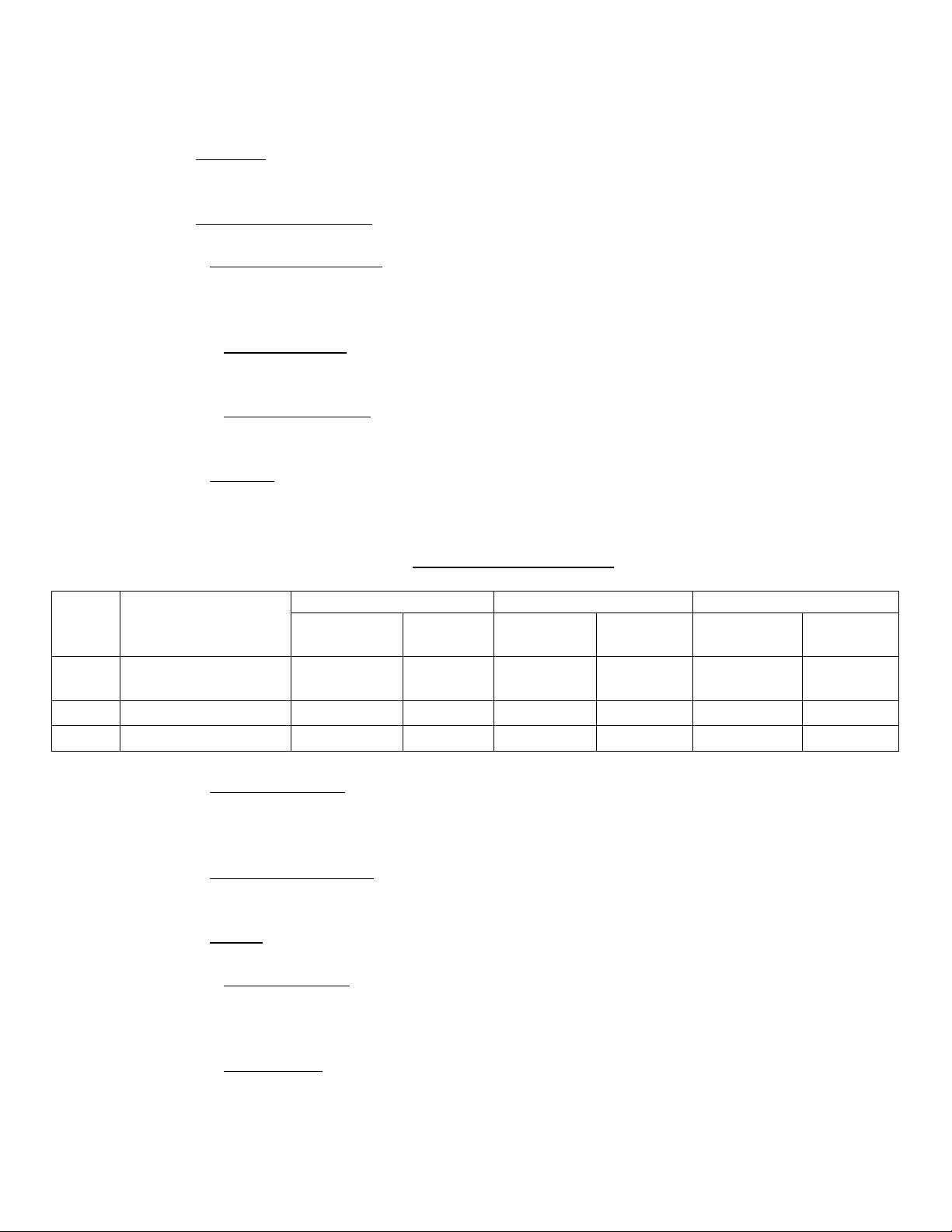

TABLE I. Shot velocity requirements.

TYPE NOMENCLATURE

AMBIENT

HOT

COLD

MEAN

(ft/s)

SD

(ft/s)

MEAN

(ft/s)

SD

(ft/s)

MEAN

(ft/s)

SD

(ft/s)

I No. 00 Buckshot 1,325 ± 50 30

1415 MAX

1198 MIN

30

1415 MAX

1198 MIN

35

II

No. 7

1

/

2

Shot

1,145 ± 90

30

II

No. 9 Shot

1,145 ± 90

30

3.5.3 Chamber pressure. The average maximum chamber pressure shall not exceed

12,500 LUP (lead units of pressure) or 13,000 PSI (pounds per square inch). The maximum

individual pressure shall not exceed 14,500 LUP or 15,000 PSI.

3.5.4 Function and casualty. The cartridge shall function without casualty in both manual

and semiautomatic shotguns.

3.5.5 Pattern. The pattern shall be as follows for the appropriate shot size:

3.5.5.1 No. 00 Buckshot. The average percentage of pellets inside or touching a 30 inch

diameter circle at a range of 40 yards shall be no less than 65 percent when fired through a 12

Ga. Shotgun with a barrel length of 29.0 ± 2.5 inches with a full choke (see 6.9).

3.5.5.2 No. 7 ½ Shot. The average percentage of pellets inside or touching a 30 inch

diameter circle at a range of 40 yards shall be no less than 70 percent when fired through a 12

Ga. Shotgun with a barrel length of 28.0 ± 2.5 inches with a full choke (see 6.9).

Source: https://assist.dla.mil -- Downloaded: 2023-04-14T17:05Z

Check the source to verify that this is the current version before use.

剩余27页未读,继续阅读

资源评论

phyit

- 粉丝: 7764

- 资源: 3191

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- 基于Html和Shell的“老罗投资/知行合一日拱一卒投资人生”主题设计源码

- 基于Java的OnlineMusic在线音乐播放器设计源码

- comsol多场耦合 水合物降压降压开采THMC,注气驱替甲烷THM,地质封存等多场耦合收敛技术,相关地质能源开采类多场耦合仿真案列分析,包括岩土类地质灾害防护,煤层气、页岩气开采,咸水封存co2,H

- 模糊逻辑控制(FLC)Matlab simulink仿真搭建模型: 提供以下帮助 波形纪录 参考文献 仿真文件 原理解释 电机参数说明 仿真原理结构和整体框图

- 基于ThinkPHP5+Vue3的RBAC权限控制前后端分离管理系统设计源码

- 基于.Net6架构的轻量级前后端分离微服务开发框架设计源码

- 主机厂基于Simulink MBD新能源电动汽车主驱电驱控制器算法模型及开发资料,量产模型,量产软件,量产代码,软件架构设计,输入输出定子,单元测试,MIL测试资料 Sumlink MCU电机控制策

- 基于微信小程序的JavaScript/TypeScript答题小程序设计源码

- 基于QT框架的语音图像识别与数据库操作综合练手小demo设计源码

- FDTD超材料吸收器吸收光谱

- 基于Vue框架的求职招聘系统移动端(Uniapp)设计源码

- 电压型同步发电机(VSG)离网仿真模型,包含电压电流双闭环,有功无功外环控制,阻抗 仅模型 MATLAB的2018以上版本都可以

- 基于MATLAB和Python的多种数据分析方法与图表生成设计源码

- 台式三轴自动螺丝机(sw16可编辑+工程图+bom)全套技术资料100%好用.zip

- 基于Vue框架的酒店管理小程序设计源码

- 基于TypeScript的鸿蒙移动应用程序个人日记本设计源码

资源上传下载、课程学习等过程中有任何疑问或建议,欢迎提出宝贵意见哦~我们会及时处理!

点击此处反馈

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功