JEDEC

STANDARD

Package Warpage Measurement of

Surface-Mount Integrated Circuits at

Elevated Temperature

JESD22-B112B

(Revision of JESD22-B112A, October 2009)

AUGUST 2018

JEDEC SOLID STATE TECHNOLOGY ASSOCIATION

NOTICE

JEDEC standards and publications contain material that has been prepared, reviewed, and

approved through the JEDEC Board of Directors level and subsequently reviewed and approved

by the JEDEC legal counsel.

JEDEC standards and publications are designed to serve the public interest through eliminating

misunderstandings between manufacturers and purchasers, facilitating interchangeability and

improvement of products, and assisting the purchaser in selecting and obtaining with minimum

delay the proper product for use by those other than JEDEC members, whether the standard is to

be used either domestically or internationally.

JEDEC standards and publications are adopted without regard to whether or not their adoption

may involve patents or articles, materials, or processes. By such action JEDEC does not assume

any liability to any patent owner, nor does it assume any obligation whatever to parties adopting

the JEDEC standards or publications.

The information included in JEDEC standards and publications represents a sound approach to

product specification and application, principally from the solid state device manufacturer

viewpoint. Within the JEDEC organization there are procedures whereby a JEDEC standard or

publication may be further processed and ultimately become an ANSI standard.

No claims to be in conformance with this standard may be made unless all requirements stated in

the standard are met.

Inquiries, comments, and suggestions relative to the content of this JEDEC standard or

publication should be addressed to JEDEC at the address below, or call (703) 624-9230 or

www.jedec.org

Published by

©JEDEC Solid State Technology Association 2018

3103 North 10th Street

Suite 240 South

Arlington, VA 22201-2107

This document may be downloaded free of charge; however JEDEC retains the

copyright on this material. By downloading this file the individual agrees not to

charge for or resell the resulting material.

PRICE: Please refer to the current

Catalog of JEDEC Engineering Standards and Publications online at

http://www.jedec.org/Catalog/catalog.cfm

Printed in the U.S.A.

All rights reserved

JEDEC Standard No. 22-B112B

Page 1

Test Method B112B

(Revision of Test Method B112A)

Package Warpage Measurement of Surface-Mount Integrated Circuits

at Elevated Temperature

(From JEDEC Board Ballot JCB-18-22, formulated under the cognizance of the JC-14.1

Subcommittee on Reliability Test Methods for Packaged Devices.)

1 Scope

The purpose of this test method is to measure the deviation from uniform flatness of an

integrated circuit package body for the range of thermal conditions experienced during the

surface-mount soldering operation.

2 Background

When integrated circuit packages are subjected to the high-temperature solder reflow operation

associated with circuit board assembly, deformation and deviation from an ideal state of uniform

planar flatness, i.e., warpage, often results. The package warpage during board assembly can

cause the package terminals to have open or short circuit connections after the reflow soldering

operation. Certain package types, such as ball grid arrays (BGAs), have been found to be more

susceptible to component warpage. Intrinsic package warpage is largely driven by coefficient of

thermal expansion mismatch between the various packaging material constituents, but can also

be affected by absorbed moisture. Package warpage is temperature dependent, and the final

warpage state is a function of the entire temperature history or reflow profile.

JESD22-B108A measures device terminal coplanarity only at room temperature and cannot be

used to predict warpage at elevated temperatures. The worst-case warpage may be at room

temperature, maximum reflow temperature, or any temperature in-between; consequently,

package warpage must be characterized during the entire reflow soldering thermal cycle.

Critical engineering evaluations of the package and printed circuit board warpage should be

conducted in the laboratory under simulated reflow conditions. For many packages, warpage

can change with continued reflow cycles so this measurement should be made and reported for

the first reflow cycle.

JEDEC Standard No. 22-B112B

Page 2

Test Method B112B

(Revision of Test Method B112A)

3 Terms and definitions

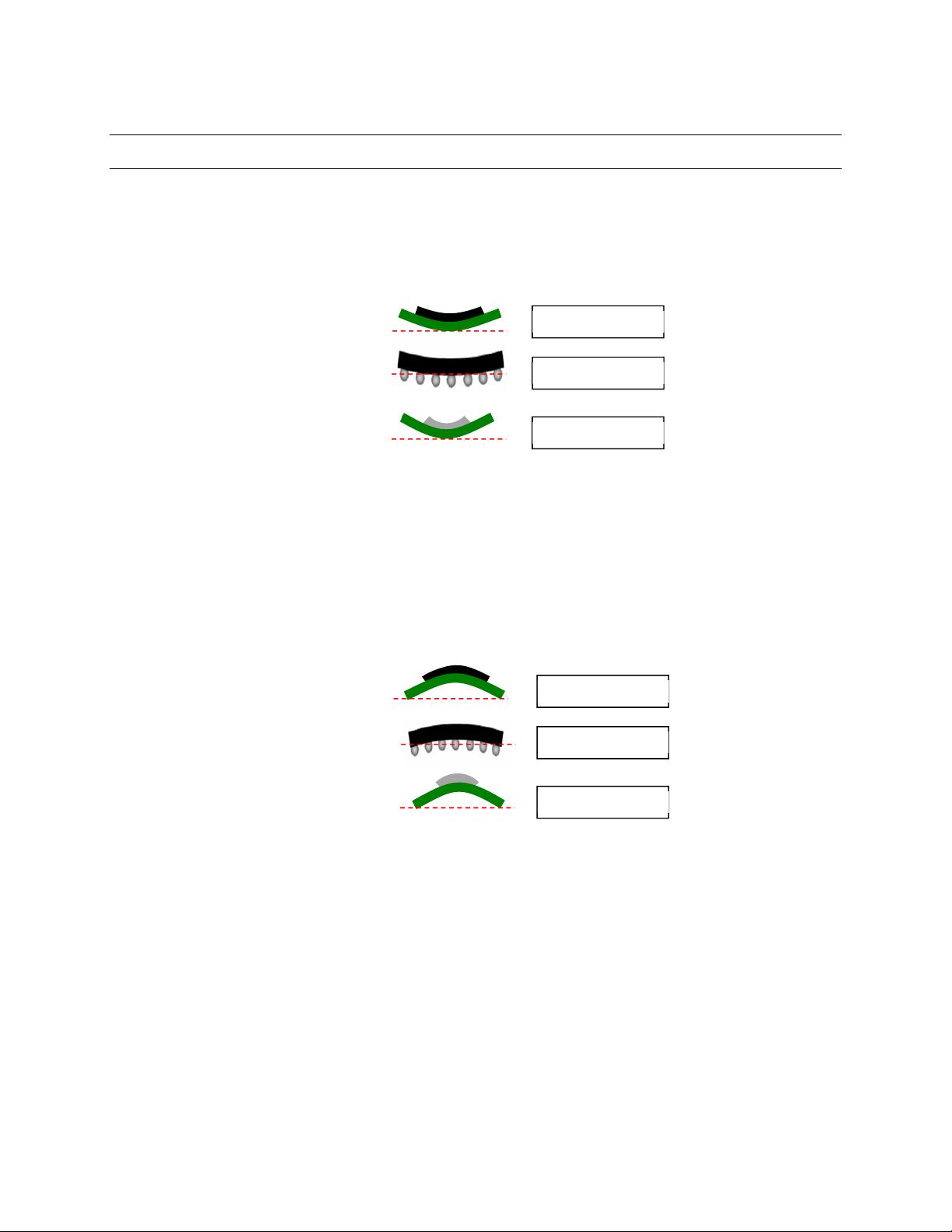

concave warpage: Negative (-) warpage resulting in the package corners being farther from

the contact plane than the center of the bottom surface of the package substrate. This is

figuratively referred as a smiling face occurrence. See Figure 1a.

Figure 1a — Package concave warpage

contact plane: A plane parallel to the reference plane passing through the lowest contact point

on the package substrate.

convex warpage: Positive (+) warpage resulting in the package corners being closer to the

contact plane than the center of the bottom surface of the package substrate. This is figuratively

referred as a frowning face occurrence. See Figure 1b.

Figure 1b — Package convex warpage

complex warpage:

Various warpage shapes that are not represented by the convex or

concave warpage such as ‘M’ shaped warpage, ‘W’ shaped warpage, or twist warpage

deviation from planarity: The difference in height between the highest point and the lowest

point on the package substrate bottom surface measured with respect to the reference plane.

digital image correlation: A 3D imaging technique utilizing multiple triangulated cameras and

computerized image matching.

fringe projection: The projection of structured light on the sample utilizing image processing to

determine package surface displacement.

Smiling (-) Concave Warpage

overmolded BGA

exposed flipchip die

Contact Plane

Contact Plane

Contact Plane

Frowning (+) Concave Warpage

overmolded BGA

exposed flipchip die

Contact Plane

Contact Plane

Contact Plane

JEDEC Standard No. 22-B112B

Page 3

Test Method B112B

(Revision of Test Method B112A)

3 Terms and definitions (cont’d)

laser reflectometry: Use of a confocal microscope to determine focal plane and thereby

measure the displacement of a surface.

package warpage: The maximum distance between the contact plane and the bottom package

surface within the measurement area.

peak reflow temperature: The maximum package reflow temperature as specified in

J-STD-020 depending on package dimensions and whether the product is intended for eutectic

Sn-Pb or Pb-free reflow soldering temperature.

rated moisture sensitivity level (MSL): The moisture sensitivity level as determined by

J-STD-020.

reference plane; regression plane: A least-squares fit of all the bottom-side or top-side

measurement points on a package.

shadow moiré: Referring to an optical noncontact method to measure warpage using a moiré

fringe pattern resulting from the geometric interference between a flat reference grating and the

projected shadow of the grating on a warped test object.

4 Reference documents (informative)

JEITA ED-7306, Measurement methods of package warpage at elevated temperature and the

maximum permissible warpage

JEP-113, Symbols and Labels for Moisture Sensitive Devices

J-STD-020, Moisture/Reflow Sensitivity Classification for Nonhermetic Solid State Surface

Mount Devices.

JESD22-A113, Preconditioning of Nonhermetic Solid State Surface Mount Components Prior to

Reliability Testing.

JESD22-B100, Physical Dimensions.

JESD22-B108, Coplanarity Test for Surface-Mount Semiconductor Devices.