POWER DRIVER FOR STEPPER MOTORS INTEGRATED CIRCUITS

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

TMC5160 / TMC5160A DATASHEET

FEATURES AND BENEFITS

2-phase stepper motors from 1 to several 10A coil current

Motion Controller with SixPoint™

ramp

Step/Dir Interface with microstep interpolation MicroPlyer™

Voltage Range 8 … 60V DC

SPI & Single Wire UART

Encoder Interface and 2x Ref.-Switch Input

Highest Resolution 256 microsteps per full step

StealthChop2™ for quiet operation and smooth motion

Resonance Dampening for mid-range resonances

SpreadCycle™ highly dynamic motor control chopper

DcStep™ load dependent speed control

StallGuard2™ high precision sensorless motor load detection

CoolStep™ current control for energy savings up to 75%

Passive Braking and freewheeling mode

Full Protection & Diagnostics

Compact Size 7x7mm

2

(body) TQFP48 package / 8x8mm² QFN

APPLICATIONS

Robotics & Industrial Drives

Textile, Sewing Machines

Packing Machines

Factory & Lab Automation

High-speed 3D Printers

Liquid Handling

Medical

Office Automation

CCTV

ATM, Cash Recycler

Pumps and Valves

DESCRIPTION

The TMC5160 / TMC5160A is a high-power

stepper motor controller and driver IC

with serial communication interfaces. It

combines a flexible ramp generator for

automatic target positioning with indus-

tries’ most advanced stepper motor

driver. Using external transistors, highly

dynamic, high torque drives can be

realized. Based on TRINAMICs sophisti-

cated SpreadCycle and StealthChop

choppers, the driver ensures absolutely

noiseless operation combined with maxi-

mum efficiency and best motor torque.

High integration, high energy efficiency

and a small form factor enable miniatu-

rized and scalable systems for cost

effective solutions. The complete solution

reduces learning curve to a minimum

while giving best performance in class.

Universal high voltage controller/driver for two-phase bipolar stepper motor. StealthChop™ for quiet

movement. External MOSFETs for 1A to several 10A coil current. With Step/Dir Interface and SPI.

BLOCK DIAGRAM

TMC5160/TMC5160A DATASHEET (Rev. 1.17 / 2022-MAY-25) 2

www.trinamic.com

APPLICATION EXAMPLES: HIGH VOLTAGE – MULTIPURPOSE USE

The TMC5160 scores with complete motion controlling features, powerful external MOSFET driver stages,

and high-quality current regulation. It offers a versatility that covers a wide spectrum of applications from

battery powered high efficiency systems up to embedded applications with 10A or more motor current per

coil. The TMC5160 contains the complete intelligence which is required to drive a motor. Receiving target

positions, the TMC5160 manages motor movement. Based on TRINAMICs unique features StallGuard2,

CoolStep, DcStep, SpreadCycle, and StealthChop, it optimizes drive performance. It trades off velocity vs.

motor torque, optimizes energy efficiency, smoothness of the drive, and noiselessness. The small form

factor of the TMC5160 keeps costs down and allows for miniaturized layouts. Extensive support at the chip,

board, and software levels enables rapid design cycles and fast time-to-market with competitive products.

High energy efficiency and reliability deliver cost savings in related systems such as power supplies and

cooling. For smaller designs, the software compatible integrated TMC5130 driver provides up to 1.4A of

motor current. The TMC5041 and TMC5072 family offer dual motor driving up to 1A, or single 2A.

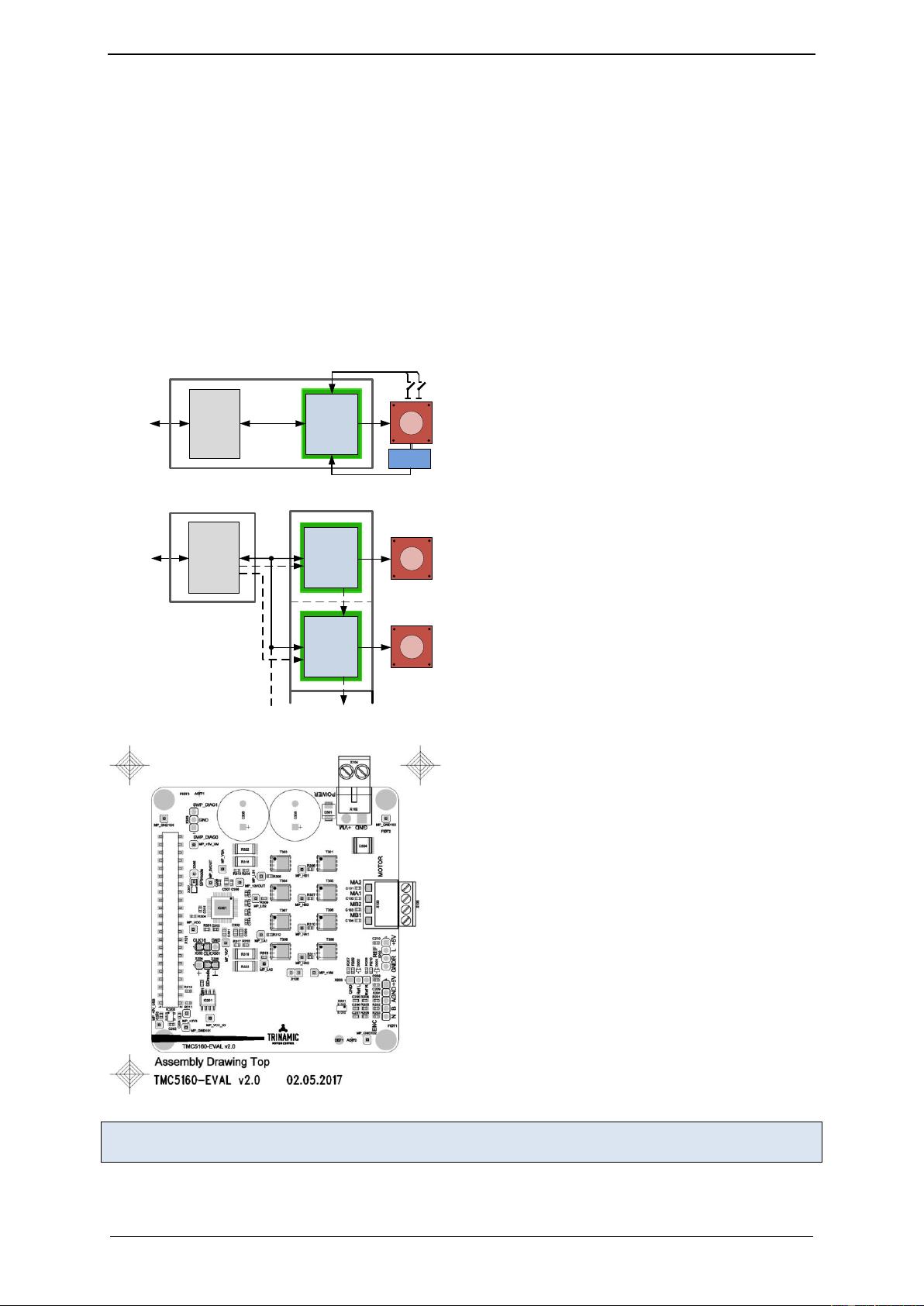

CPU

TMC5160

High-Level

Interface

SPI

CPU

High-Level

Interface

TMC5160

TMC5160

More TMC5160 or TMC5130 or TMC5072

SPI or

UART

MINIATURIZED DESIGN FOR ONE STEPPER MOTOR

COMPACT DESIGN FOR MULTIPLE STEPPER MOTORS

M

Encoder

Ref.

Switches

M

M

Addr.

Addr.

NCS signal for SPI

Chaining

with UART

Hint: TMC5160 in this manual always refers to both, the TMC5160A and TMC5160, unless explicitly noted

with “non-A-version” or “A-version”. The A-version compatibly replaces the non-A-version.

An optional ABN encoder interface with

scaler unit and two reference switch inputs

are used to ensure correct motor movement.

Automatic interrupt upon deviation is

available.

An application with 2 stepper motors is

shown. Additionally, the ABN Encoder

interface and two reference switches can be

used for each motor. A single CPU controls

the whole system, as there are no real time

tasks required to move a motor. The CPU-

board and the controller / driver boards are

highly economical and space saving.

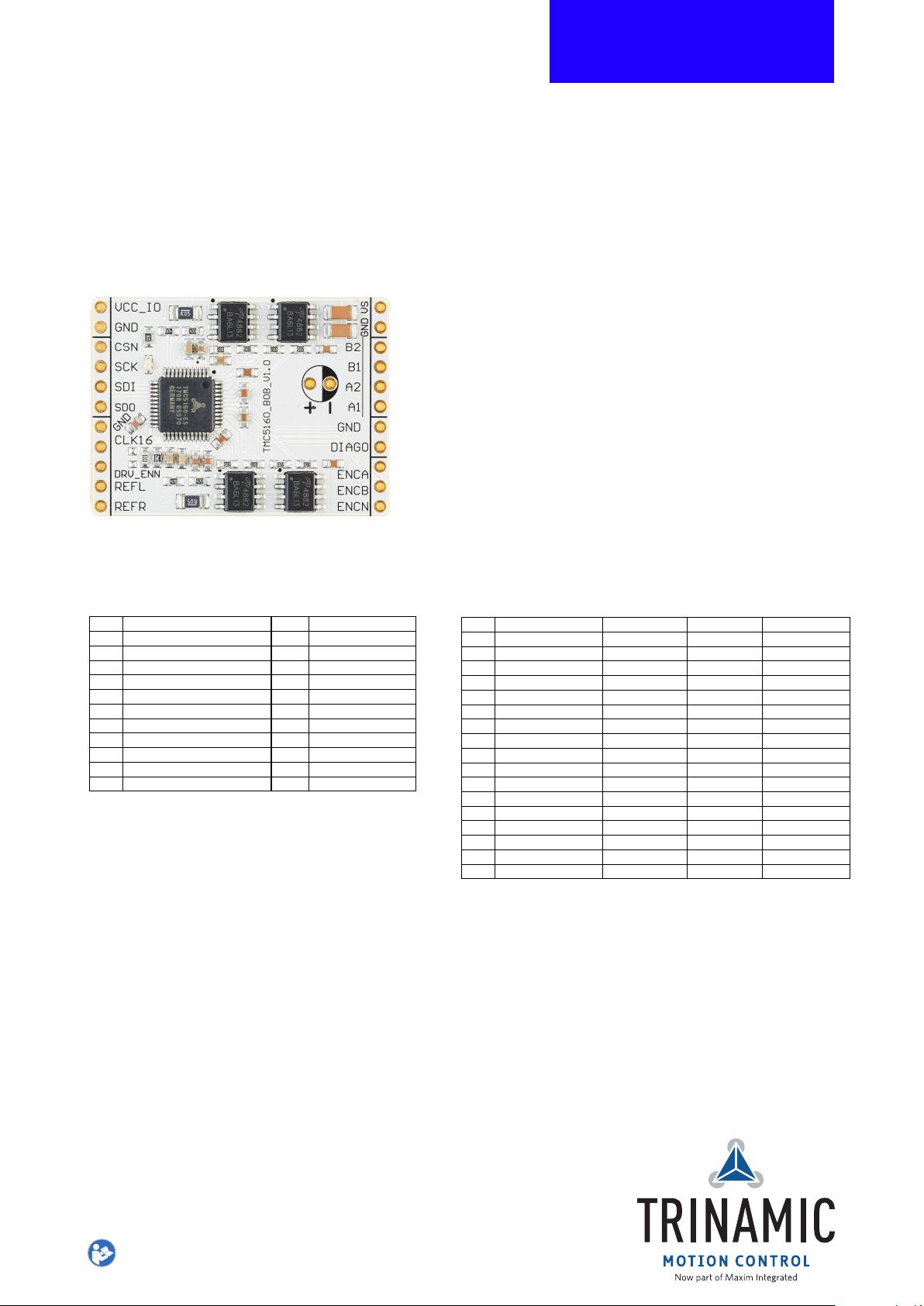

The TMC5160-EVAL is part of TRINAMICs

universal evaluation board system which

provides a convenient handling of the

hardware as well as a user-friendly

software tool for evaluation. The

TMC5160 evaluation board system

consists of three parts:

LANDUNGSBRÜCKE (base board),

ESELSBRÜCKE (connector board including

several test points), and TMC5160-EVAL.

TMC5160/TMC5160A DATASHEET (Rev. 1.17 / 2022-MAY-25) 3

www.trinamic.com

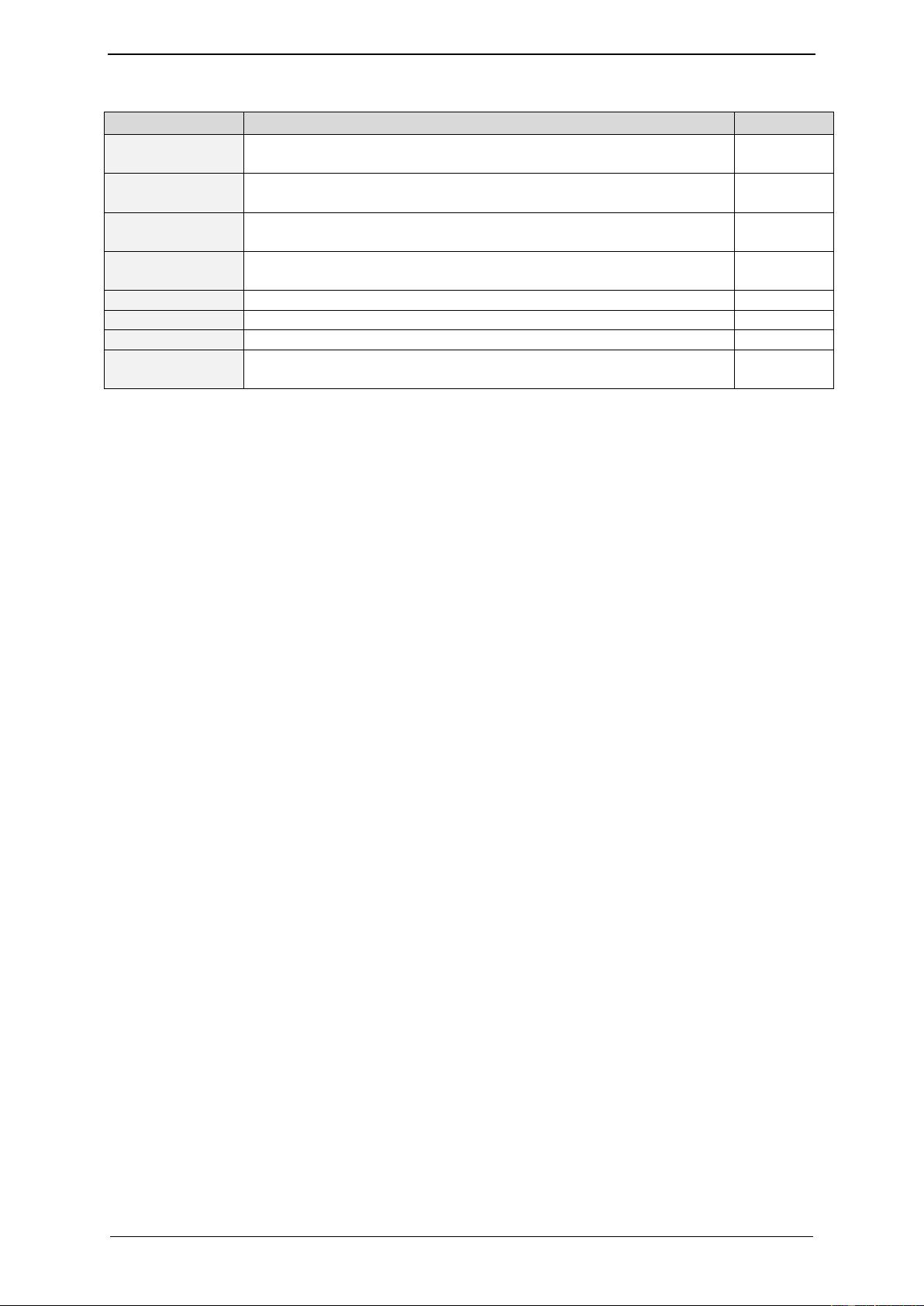

ORDER CODES

Order code

Description

Size [mm

2

]

TMC5160A-TA

Stepper Motor Controller/Driver IC, SPI, Step/Dir, UART, 8-60V,

eTQFP48, Tray

7 x 7 (body)

TMC5160A-TA-T

Stepper Motor Controller/Driver IC, SPI, Step/Dir, UART, 8-60V,

eTQFP48, Tape & Reel

7 x 7 (body)

TMC5160A-WA

Stepper Motor Controller/Driver IC, SPI, Step/Dir, UART, 8-60V, QFN56

Wettable Flanks, Tray

8 x 8

TMC5160A-WA-T

Stepper Motor Controller/Driver IC, SPI, Step/Dir, UART, 8-60V, QFN56

Wettable Flanks, Tape & Reel

8 x 8

TMC5160-EVAL-KIT

Full Evaluation Kit for TMC5160

126 x 85

TMC5160-EVAL

Evaluation Board for TMC5160 (excl. Landungsbrücke and Eselsbrücke)

85 x 55

TMC5160-BOB

Breakout Board with TMC5160

38 x 28

TMC5160Silent

StepStick

Step Direction Driver Board with TMC5160

20 x 15

Table of Contents

1 PRINCIPLES OF OPERATION ......................... 5

1.1 KEY CONCEPTS ................................................ 6

1.2 CONTROL INTERFACES ..................................... 7

1.3 SOFTWARE ...................................................... 7

1.4 MOVING AND CONTROLLING THE MOTOR ........ 8

1.5 AUTOMATIC STANDSTILL POWER DOWN......... 8

1.6 STEALTHCHOP2 & SPREADCYCLE DRIVER ....... 8

1.7 STALLGUARD2 – MECHANICAL LOAD SENSING .

....................................................................... 9

1.8 COOLSTEP – LOAD ADAPTIVE CURRENT .......... 9

1.9 DCSTEP – LOAD DEPENDENT SPEED ............. 10

1.10 ENCODER INTERFACE ..................................... 10

2 PIN ASSIGNMENTS ......................................... 11

2.1 PACKAGE OUTLINE ........................................ 11

2.2 SIGNAL DESCRIPTIONS ................................. 12

3 SAMPLE CIRCUITS .......................................... 15

3.1 STANDARD APPLICATION CIRCUIT ................ 15

3.2 EXTERNAL GATE VOLTAGE REGULATOR .......... 16

3.3 CHOOSING MOSFETS AND SLOPE ................ 17

3.4 TUNING THE MOSFET BRIDGE ..................... 19

3.5 HIGHER VOLTAGE APPLICATIONS .................. 22

4 SPI INTERFACE ................................................ 23

4.1 SPI DATAGRAM STRUCTURE ......................... 23

4.2 SPI SIGNALS ................................................ 24

4.3 TIMING ......................................................... 25

5 UART SINGLE WIRE INTERFACE ................ 26

5.1 DATAGRAM STRUCTURE ................................. 26

5.2 CRC CALCULATION ....................................... 28

5.3 UART SIGNALS ............................................ 28

5.4 ADDRESSING MULTIPLE SLAVES .................... 29

6 REGISTER MAPPING ....................................... 31

6.1 GENERAL CONFIGURATION REGISTERS .......... 32

6.2 VELOCITY DEPENDENT DRIVER FEATURE

CONTROL REGISTER SET ............................................. 38

6.3 RAMP GENERATOR REGISTERS ...................... 40

6.4 ENCODER REGISTERS .................................... 45

6.5 MOTOR DRIVER REGISTERS ........................... 47

7 STEALTHCHOP™ .............................................. 57

7.1 AUTOMATIC TUNING ..................................... 57

7.2 STEALTHCHOP OPTIONS ............................... 60

7.3 STEALTHCHOP CURRENT REGULATOR ............ 60

7.4 VELOCITY BASED SCALING ........................... 63

7.5 COMBINE STEALTHCHOP AND SPREADCYCLE 64

7.6 FLAGS IN STEALTHCHOP ............................... 66

7.7 FREEWHEELING AND PASSIVE BRAKING ........ 66

8 SPREADCYCLE AND CLASSIC CHOPPER ... 68

8.1 SPREADCYCLE CHOPPER ................................ 69

8.2 CLASSIC CONSTANT OFF TIME CHOPPER ...... 72

9 SELECTING SENSE RESISTORS .................... 74

10 VELOCITY BASED MODE CONTROL ....... 76

11 DIAGNOSTICS AND PROTECTION......... 78

11.1 TEMPERATURE SENSORS ................................ 78

11.2 SHORT PROTECTION ...................................... 78

11.3 OPEN LOAD DIAGNOSTICS ........................... 80

12 RAMP GENERATOR ..................................... 81

12.1 REAL WORLD UNIT CONVERSION ................. 81

12.2 MOTION PROFILES ........................................ 82

12.3 VELOCITY THRESHOLDS ................................. 84

12.4 REFERENCE SWITCHES .................................. 85

12.5 RAMP GENERATOR RESPONSE TIME .............. 86

13 STALLGUARD2 LOAD MEASUREMENT ... 87

13.1 TUNING STALLGUARD2 THRESHOLD SGT ..... 88

13.2 STALLGUARD2 UPDATE RATE AND FILTER .... 90

13.3 DETECTING A MOTOR STALL ......................... 90

TMC5160/TMC5160A DATASHEET (Rev. 1.17 / 2022-MAY-25) 4

www.trinamic.com

13.4 HOMING WITH STALLGUARD ......................... 90

13.5 LIMITS OF STALLGUARD2 OPERATION .......... 90

14 COOLSTEP OPERATION ............................. 91

14.1 USER BENEFITS ............................................. 91

14.2 SETTING UP FOR COOLSTEP .......................... 91

14.3 TUNING COOLSTEP ....................................... 93

15 STEP/DIR INTERFACE ................................ 94

15.1 TIMING ......................................................... 94

15.2 CHANGING RESOLUTION ................................ 95

15.3 MICROPLYER AND STAND STILL DETECTION . 96

16 DIAG OUTPUTS ........................................... 97

16.1 STEP/DIR MODE ......................................... 97

16.2 MOTION CONTROLLER MODE ........................ 97

17 DCSTEP........................................................... 99

17.1 USER BENEFITS ............................................. 99

17.2 DESIGNING-IN DCSTEP ................................. 99

17.3 DCSTEP INTEGRATION WITH THE MOTION

CONTROLLER............................................................ 100

17.4 STALL DETECTION IN DCSTEP MODE ......... 100

17.5 MEASURING ACTUAL MOTOR VELOCITY IN

DCSTEP OPERATION ................................................ 101

17.6 DCSTEP WITH STEP/DIR INTERFACE ........ 102

18 SINE-WAVE LOOK-UP TABLE ................ 105

18.1 USER BENEFITS .......................................... 105

18.2 MICROSTEP TABLE ..................................... 105

19 EMERGENCY STOP .................................... 106

20 ABN INCREMENTAL ENCODER

INTERFACE .............................................................. 107

20.1 ENCODER TIMING ....................................... 108

20.2 SETTING THE ENCODER TO MATCH MOTOR

RESOLUTION ............................................................ 108

20.3 CLOSING THE LOOP .................................... 109

21 DC MOTOR OR SOLENOID .................... 110

21.1 SOLENOID OPERATION ............................... 110

22 QUICK CONFIGURATION GUIDE .......... 111

23 GETTING STARTED ................................... 116

23.1 INITIALIZATION EXAMPLES ......................... 116

24 STANDALONE OPERATION .................... 117

25 POWER-UP RESET ..................................... 119

26 CLOCK OSCILLATOR AND INPUT ......... 119

26.1 USING THE INTERNAL CLOCK ...................... 119

26.2 USING AN EXTERNAL CLOCK ....................... 119

27 ABSOLUTE MAXIMUM RATINGS .......... 120

28 ELECTRICAL CHARACTERISTICS .......... 120

28.1 OPERATIONAL RANGE ................................. 120

28.2 DC AND TIMING CHARACTERISTICS ............ 121

28.3 THERMAL CHARACTERISTICS........................ 123

29 LAYOUT CONSIDERATIONS................... 125

29.1 EXPOSED DIE PAD ...................................... 125

29.2 WIRING GND ............................................ 125

29.3 WIRING BRIDGE SUPPLY ............................ 125

29.4 SUPPLY FILTERING ...................................... 125

29.5 LAYOUT EXAMPLE ....................................... 126

30 PACKAGE MECHANICAL DATA .............. 128

30.1 DIMENSIONAL DRAWINGS TQFP48-EP ..... 128

30.2 DIMENSIONAL DRAWINGS QFN-WA ......... 130

30.3 PACKAGE CODES ......................................... 131

31 DESIGN PHILOSOPHY ............................. 132

32 DISCLAIMER ............................................... 132

33 ESD SENSITIVE DEVICE.......................... 132

34 DESIGNED FOR SUSTAINABILITY ....... 132

35 TABLE OF FIGURES .................................. 133

36 REVISION HISTORY ................................. 134

37 REFERENCES ............................................... 134

TMC5160/TMC5160A DATASHEET (Rev. 1.17 / 2022-MAY-25) 5

www.trinamic.com

1 Principles of Operation

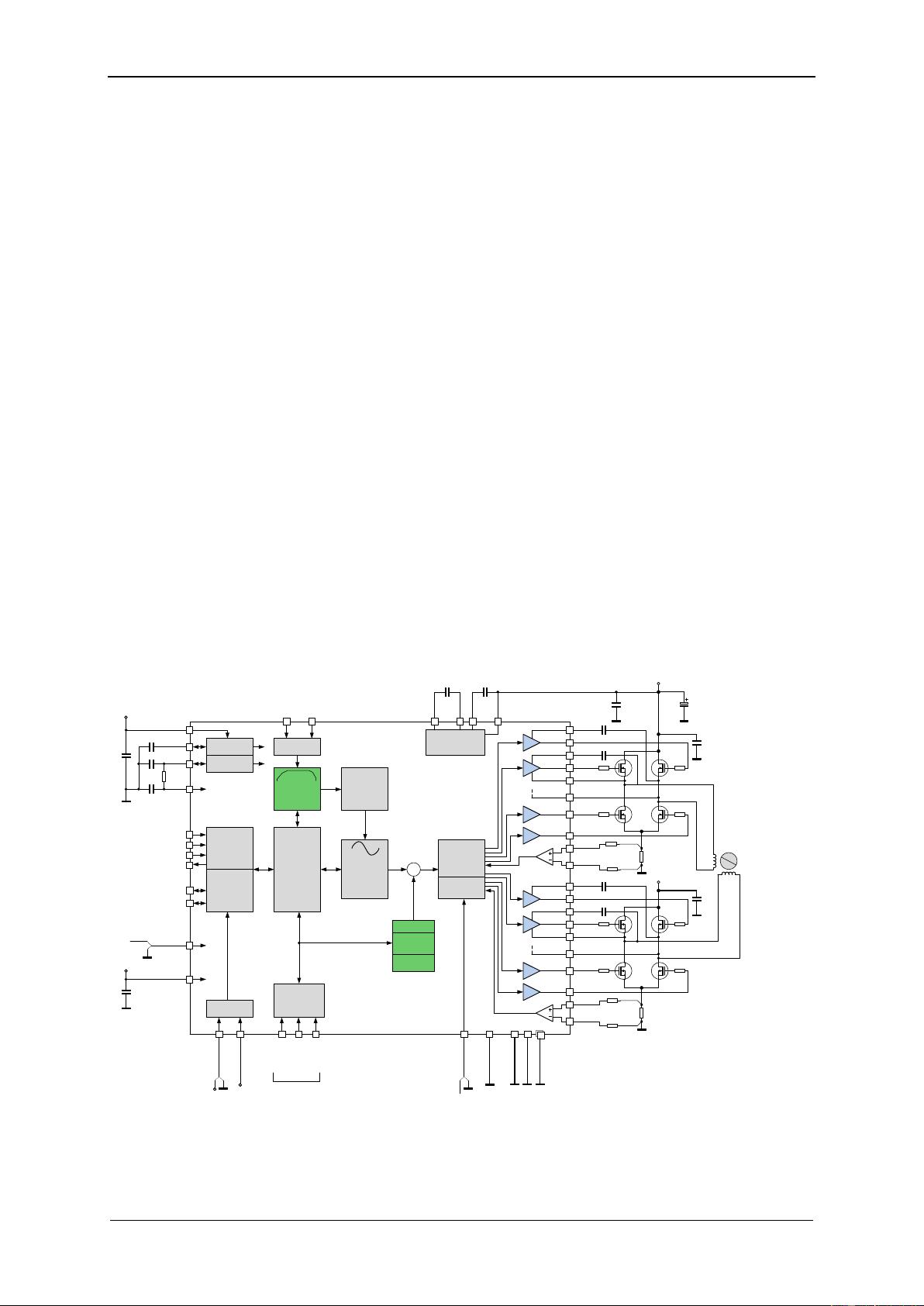

The TMC5160 motion controller and driver chip is an intelligent power component interfacing between

CPU and a high-power stepper motor. All stepper motor logic is completely within the TMC5160. No

software is required to control the motor – just provide target positions. The TMC5160 offers several

unique enhancements which are enabled by the system-on-chip integration of driver and controller.

The SixPoint ramp generator of the TMC5160 uses StealthChop, DcStep, CoolStep, and StallGuard2

automatically to optimize every motor movement. The TMC5160 ideally extends the TMC2100, TMC2130

and TMC5130 family to higher voltages and higher motor currents.

THE TMC5160 OFFERS THREE BASIC MODES OF OPERATION:

MODE 1: Full Featured Motion Controller & Driver

All stepper motor logic is completely within the TMC5160. No software is required to control the

motor – just provide target positions. Enable this mode by tying low pin SD_MODE.

MODE 2: Step & Direction Driver

An external high-performance S-ramp motion controller like the TMC4361 or a central CPU generates

step & direction signals synchronized to other components like additional motors within the system.

The TMC5160 takes care of intelligent current and mode control and delivers feedback on the state of

the motor. The MicroPlyer automatically smoothens motion. Tie SD_MODE high.

MODE 3: Simple Step & Direction Driver

The TMC5160 positions the motor based on step & direction signals. The MicroPlyer automatically

smoothens motion. No CPU interaction is required; configuration is done by hardware pins. Basic

standby current control can be done by the TMC5160. Optional feedback signals allow error detection

and synchronization. Enable this mode by tying pin SPI_MODE low and SD_MODE high.

47R

47R

LS

VCC_IO

TMC5160

SPI interface

CSN

SCK

SDO

SDI

Ref. switch

processing

REFL/STEP

REFR/DIR

DIAG / INT out

and

Single wire

interface

5V Voltage

regulator

charge pump

22n

100V

100n

16V

DIAG0/SWN

CLK_IN

DIAG1/SWP

+V

M

5VOUT

VSA

2.2µ

+V

IO

DRV_ENN

GNDD

GNDA

TST_MODE

DIE PAD

VCC

opt. ext. clock

12-16MHz

3.3V or 5V

I/O voltage

100n

100n

LS

stepper

motor

N

S

BMA2

100n

SRAH

C

E

2R2

470n

Encoder

unit

A B N

ENCB_DCEN

ENCA_DCIN

ENCN_DCO

Encoder input /

dcStep control in S/D

mode

SD_MODE

SPI_MODE

opt. driver enable

B.Dwersteg, ©

TRINAMIC 2014

R

S

SRAL

LA1

LA2

HA1

HA2

BMA1

HS

HS

CA1

C

B

CA2

C

B

+V

M

LS

LS

BMB2

SRBH

R

S

SRBL

LB1

LB2

HB1

HB2

BMB1

HS

HS

CB1

C

B

CB2

C

B

+V

M

Both GND: UART mode

CPI

CPO

VCP

VS

11.5V Voltage

regulator

12VOUT

2.2µ

mode selection

470n

470n

R

G

R

G

R

G

R

G

R

G

R

G

R

G

R

G

47R

47R

+V

IO

pd pd pd

+V

IO

Stepper driver

Protection

& diagnostics

spreadCycle &

stealthChop

Chopper

programmable

sine table

4*256 entry

stallGuard2™

coolStep™

x

linear 6 point

RAMP generator

Step &

Direction pulse

generation

Control register

set

Interface

dcStep™

coolStep

&

stealthChop

motor driver

B.Dwersteg, ©

TRINAMIC 2014

Motion control

Figure 1.1 TMC5160 basic application block diagram (motion controller)