174

IEEE

TRANSACTIONS ON

ROBOTICS

AND

AUTOMATION,

VOL.

9,

NO.

2,

APRIL

1993

A

Linear Solution to the Kinematic Parameter

Identification

of

Robot Manipulators

Hanqi Zhuang,

Member, IEEE,

and Zvi

S.

Roth,

Senior Member, IEEE

Abstruct-

An important step in a model-based robot calibra-

tion process is the identification of the manipulator’s unknown

kinematic model parameters from end-effector pose measure-

ments and robot joint position readings at known measurement

configurations. A linear solution method for the unknown kine-

matic parameters directly from the forward kinematic model is

presented. The proposed method requires the use of neither a

nominal model nor a linearized error model of the robot. Such

a solution is possible for two reasons:

1)

the use of a special

robot kinematic modeling convention known as the CPC model,

in which the independent CPC link parameters appear linearly in

the system of equations to be solved; and

2)

the use of a particular

sequence of robot pose measurements. The CPC orientation

parameters of the revolute joints are first determined recursively

under the condition that the pose measurements of the robot

are taken while releasing each revolute joint one at a time and

successively. The remaining CPC parameters are then computed

in terms of the orientation parameters obtained earlier.

For

explicit solution formulas of an

TI

degree-of-freedom manipulator,

end-effector pose measurements from

n

+

1

configurations need

to be acquired. Additional pose measurements can be handled

by least squares techniques. Some practical issues related to

kinematic parameter identification with the proposed approach

are addressed through simulation studies.

I. INTRODUCTION

INEMATIC IDENTIFICATION is the process by which

K

all kinematic model parameters of a robot manipulator

are identified given a set of end-effector pose measurements

and the corresponding joint position measurements. This is an

important phase in a model-based robot calibration

[

1

I-[3].

Determining kinematic parameters directly from the kine-

matic model given the measurement data, although appealing

both theoretically and practically, is difficult since pose com-

ponents of the robot end-effector are in general nonlinear func-

tions of the robot link parameters. Linearization techniques

have been widely used to construct kinematic error models

relating robot pose errors to its kinematic parameter errors,

based on which kinematic parameter deviations are found

by iteratively solving linear least squares problems

[3]-[

121.

This type of technique often allows effective implementa-

tion and requires a relatively small number of measurement

configurations. A fairly extensive off-line simulation study

is often required to determine, for each individual robot,

the number of and the optimal choice of measurement con-

figurations to ensure a reasonably small condition number

for the “Identification Jacobian”

[

1314 151. Kinematic error

parameters often lack a simple geometric interpretation. For

example, as some of the robot pose error sources correspond

to joint axis misalignment, an actual joint rotation

8i

and

a nominal joint rotation

are,

in general, rotations with

respect to different lines in space. An error parameter

6Bi

is

therefore not the joint position encoder offset but an element

in a set of abstract mathematical entities which account for

robot pose errors in the least squares sense. For the linearized

error model to be valid, the nominal model of the robot has

to be sufficiently close to the actual model. Although certain

nonlinear optimization algorithms may be applied to handle

large parameter deviations, their convergence properties need

to be established for each case.

An alternative case of robot kinematic identification tech-

niques consists of extracting the kinematic parameters from

identified orientation and position of the joint axes obtained by

tracking one or more target points located on the robot, while

moving each robot one joint at a time through a significant

portion

of

the joint travel [16]-[ 181. The technique is attractive

for studying joint imperfections. It allows an estimation of joint

features (such as center of rotation, plane of rotation, etc.)

from relatively noisy measurements of the target positions.

A disadvantage of the method is that in order to increase

the robustness of the identification, a relatively large number

of target position measurements need to be taken to perform

least squares curve fitting to a target trajectory resulting from

joint motion of each identified joint axis

[

171,

[

181. The shape

matrix approach proposed by Broderick and Cipra [19] also

employed a measurement strategy by which each joint is

individually and successively moved. A similar measurement

strategy was employed by Lenz and Tsai [20] for calibration

of a Cartesian robot.

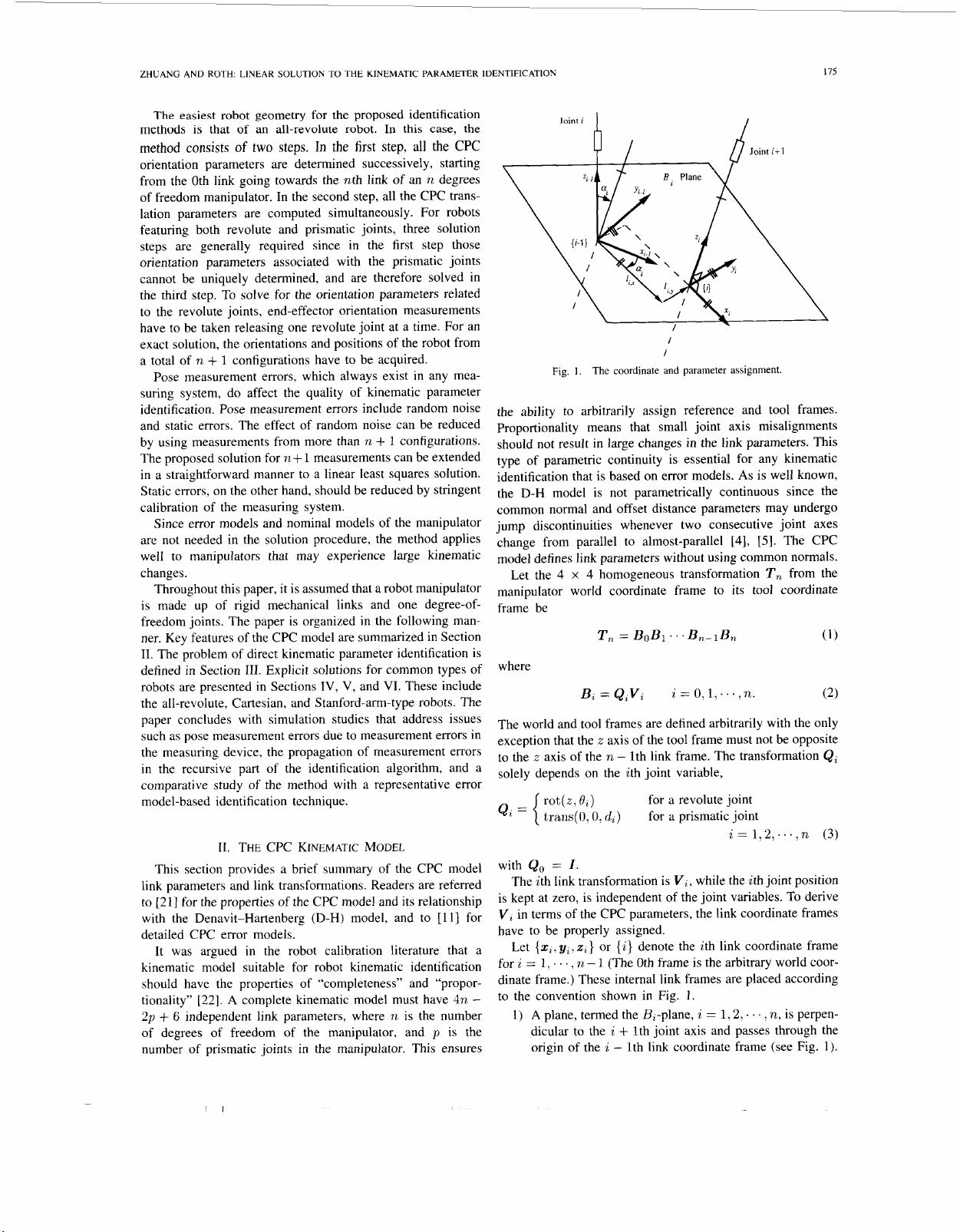

This paper presents a linear solution for the identification

of unknown robot kinematic parameters. The solution method

employs a recently proposed robot kinematic modeling con-

vention termed the Complete and Parametrically Continuous

(CPC) model [lo], [21]. One reason for choosing the CPC

model is that there exists a sequence of pose measurements

for which all CPC link parameters except for one appear

linearly in the system of equations to be solved. Another

Manuscript received

June

14,

1991; revised July

8,

1992. Portions

of

this

paper were presented at the IEEE International Conference

on

Robotics and

is

that

the

redundant

parameters

in

the

‘pc

can be systematically eliminated, which is a crucial step in

Automation,- Sacramento, CA, May 1991.

334314991.

the solution method. While the pose measurements procedure

resembles the one used for joint axis identification, it involves

The authors are with the Florida Atlantic University,

Boca

Raton, FL

IEEE Log

Number

9207356.

a drastically reduced number of pose measurements.

1042-296X/93$03.00

0

1993 IEEE

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功