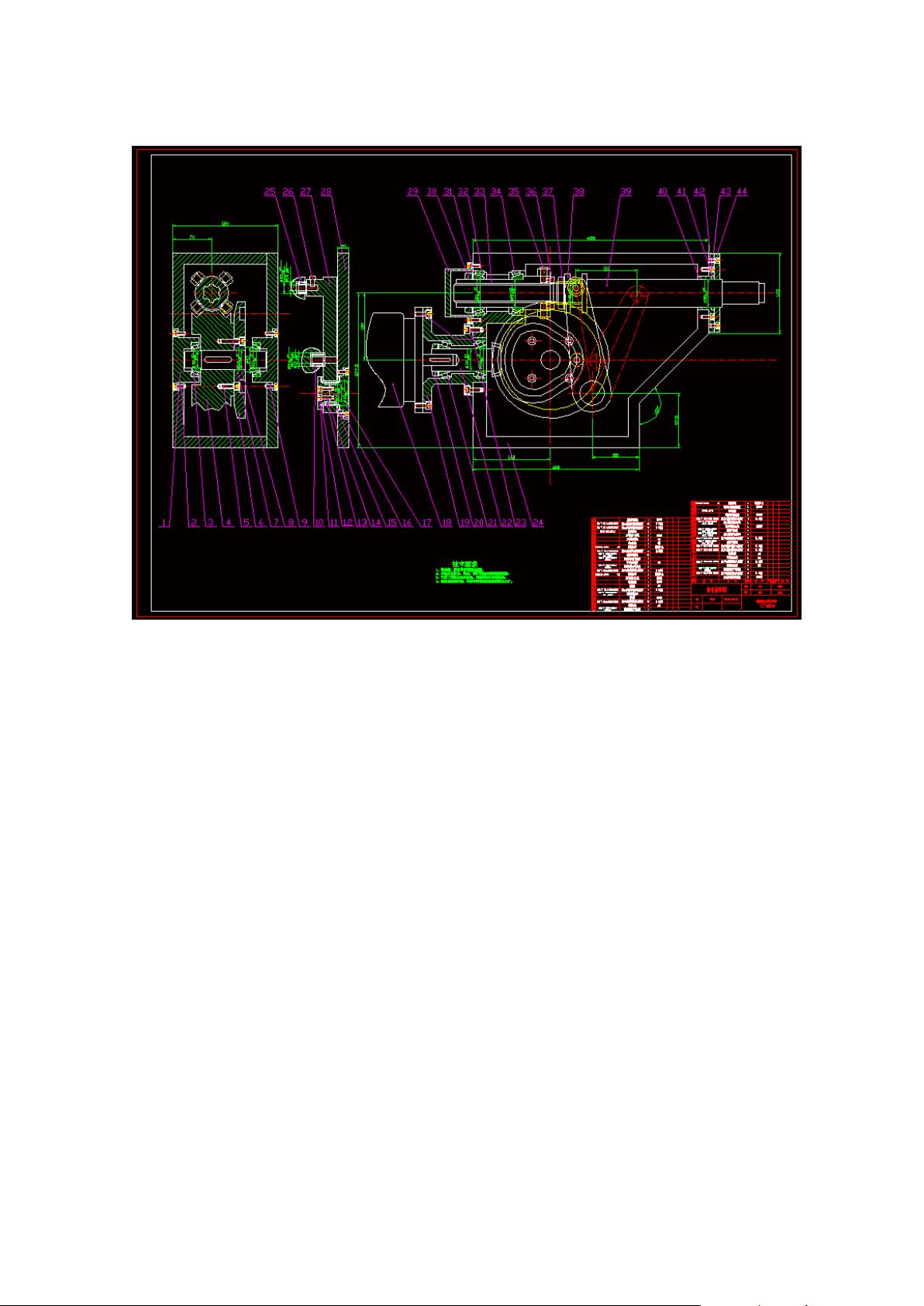

在现代制造业中,随着自动化和智能化水平的不断提高,自动换刀机械手的设计变得尤为重要。自动换刀机械手是加工中心的核心组件之一,它使机床能够在一次装夹中完成铣削、钻孔、镗孔、铰孔、攻丝等多种工序的加工任务,从而大大提高了加工效率和加工精度。 自动换刀机械手的设计主要围绕着其核心功能——自动更换刀具展开。这一功能的实现依赖于机床的自动换刀系统,该系统通常由刀库和机械手两大部分组成。刀库负责储存备用刀具,而机械手则负责刀具的选取和更换工作。自动换刀(ATC)功能是衡量加工中心技术水平的一个重要标志。 在自动换刀机械手的设计中,刀库和机械手之间的配合尤为重要。机械手的设计需要确保能够快速、准确地将所需刀具从刀库中取出,并安装到主轴上。与此同时,它还应该能够将使用过的刀具迅速地返回刀库,以便下一次使用。这种换刀动作的高效性对于缩短非切削时间、提升加工效率至关重要。 在自动换刀机械手的设计上,还需注重机械手的结构和驱动方式的选择。现代自动换刀机械手多采用电动驱动,相比液压驱动具有结构简单、工作可靠、维护简便等优点。电动驱动的机械手可以更精准地控制刀具的选取和更换动作,同时避免了液压系统可能出现的漏油问题。此外,机械手手臂的回转和刀具的插入拔出动作是联动的,可以实现部分动作时间的重叠,这进一步缩短了换刀时间。 在选择机械手时,需要综合考虑加工中心的技术要求和生产需求。机械手的负载能力、定位精度、速度和加速度等参数都必须满足特定加工工艺的需要。例如,对于高精度加工要求,就需要选用定位精度更高、速度更快的机械手。而对于大批量生产,则可能需要选择能够承受高频率换刀动作且可靠性高的机械手。 除了上述技术要求之外,自动换刀机械手的设计还必须充分考虑到安全性和可靠性。机械手的操作动作要确保安全,避免在运行过程中发生碰撞或其他意外事故,对操作人员和机床设备造成损害。同时,设计应保证机械手在长期运行中具备高度的可靠性,不会因故障而频繁停机,保证加工中心的持续运行能力。 自动换刀机械手的设计是一项复杂而精细的工作,它涉及到机械设计、电子控制、自动化技术等多个领域。合理的自动换刀机械手设计需要根据加工中心的具体需求,综合考虑技术参数、生产效率、操作安全、设备可靠等多方面因素,才能确保加工中心在实际应用中能够达到高效、稳定、安全的生产目的。随着科技的不断进步,自动换刀机械手的设计将更加智能化和人性化,为现代制造业的发展提供更加强大的支持。

剩余59页未读,继续阅读

- 粉丝: 389

- 资源: 8万+

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- 车用驱动电机原理与控制基础-P140公式(6-57)~(6-58)

- MATLAB编程入门指南:环境搭建、基础语法及实用功能

- Oracle SQL Developer Data Modeler:数据建模与模型文档化及分享的最佳实践

- 使用 Python 为新年创建倒数计时器

- python语言huochepiao爬虫程序代码QZQ1.txt

- 2025 年新年快乐 -使用 HTML、CSS 和 JavaScript 设计新年贺卡

- Java毕设项目:基于spring+mybatis+maven+mysql实现的小区停车管理系统【含源码+数据库+毕业论文】

- Java毕设项目:基于spring+mybatis+maven+mysql实现的校园车辆管理系统【含源码+数据库+开题报告+毕业论文】

- 如何使用 Python 创建倒数计时器?

- Java毕设项目:基于spring+mybatis+maven+mysql实现的学生公寓管理系统【含源码+数据库+答辩PPT+毕业论文】

- 电子产品IM端子自动组装机sw14全套技术资料100%好用.zip

- Java毕设项目:基于spring+mybatis+maven+mysql实现的电动车租赁管理系统【含源码+数据库+毕业论文】

- 基于java的酒店客房管理系统的开题报告.docx

- 基于java的酒店预约及管理系统的开题报告.docx

- 电芯铝塑膜冲坑机sw14全套技术资料100%好用.zip

- 基于java的旅游攻略网站的开题报告.docx

信息提交成功

信息提交成功