通过原子层沉积制造的高性能基于HfOx / AlOy的电阻开关存储器交叉点阵列

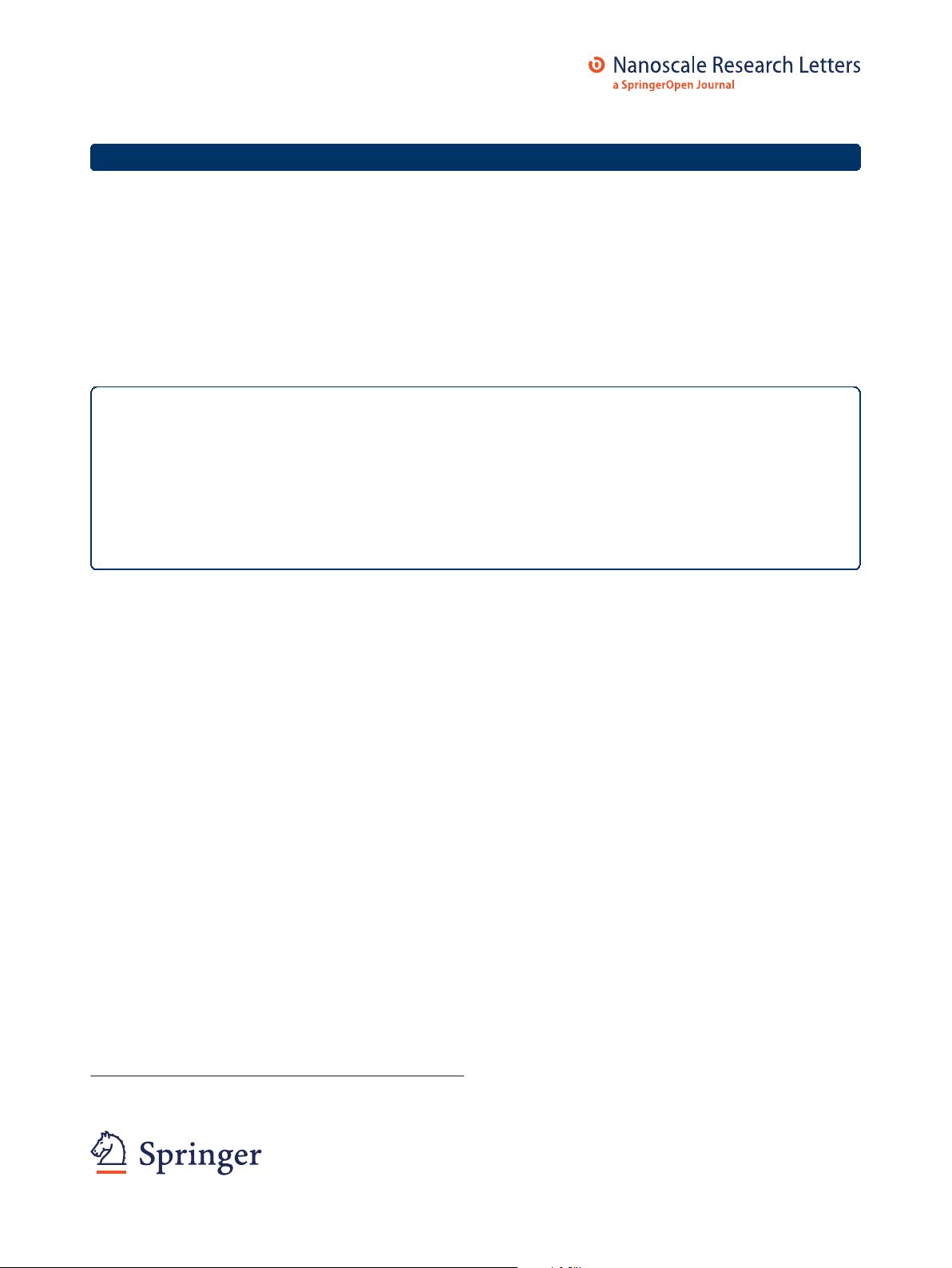

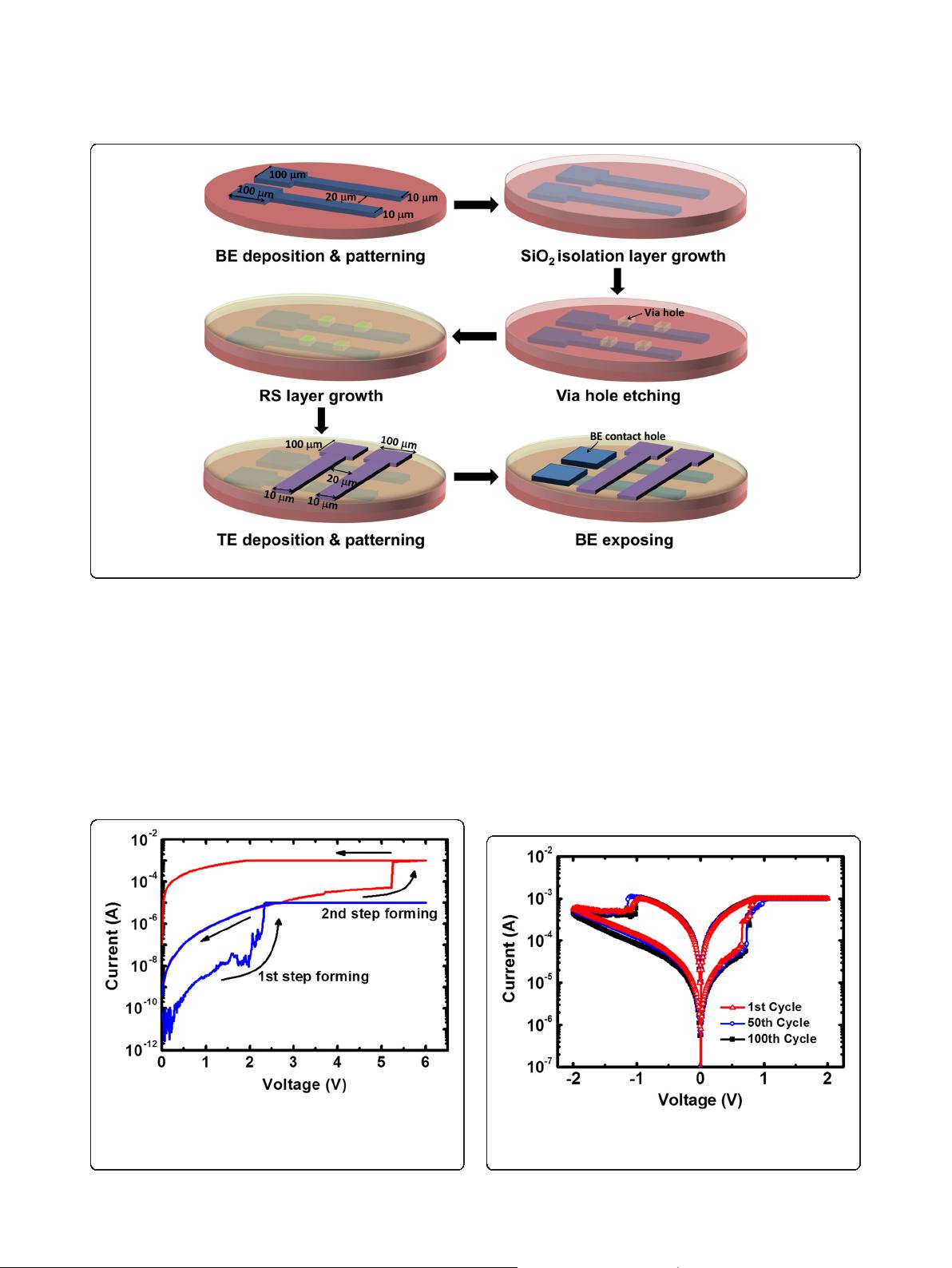

标题涉及的知识点有:原子层沉积技术(Atomic Layer Deposition, ALD)、基于HfOx和AlOy的电阻开关存储器(Resistive Switching Memory)、交叉点阵列(Cross-Point Array)。 描述主要强调的是,利用原子层沉积技术制造出的含有HfOx/AlOy双层结构的高性能电阻开关存储器交叉点阵列。这种存储器阵列表现出低开关电压、大电阻比、良好的循环一致性和器件间一致性,以及高产量等优秀性能。此外,还表现出多级数据存储能力和稳健的可靠性特点。这些成果展示了原子层沉积法制备的HfOx/AlOy双层结构在未来非易失性存储器应用中的巨大潜力。 从标签“研究论文”来看,本文属于学术研究范畴,研究的内容涉及新型存储技术的探索和实现。 从提供的部分内容来看,可以提取出以下详细知识点: 1. 电阻开关存储器(Resistive Random Access Memory, RRAM):一种基于金属氧化物的存储技术,被认为是下一代非易失性存储器的最有前景的候选之一。它拥有快速的开关速度、低操作电压、良好的3D集成能力,以及与CMOS制造工艺的良好兼容性。RRAM的核心是电阻开关材料,这类材料在施加电压后可以改变其电阻状态,实现数据的存储。 2. 原子层沉积技术(Atomic Layer Deposition, ALD):一种可以实现精确控制薄膜厚度和一致性的纳米制造技术,通过自限制化学反应过程,在基板上逐层沉积材料。ALD技术可以实现原子级的均匀性和平整度,非常适合于纳米尺度的电子元件生产。 3. 基于HfOx和AlOy的电阻开关膜:HfOx和AlOy是两种常用于RRAM的金属氧化物。HfOx被认为是优异的电阻开关材料,具有稳定的电学特性、良好的工艺可重复性以及低漏电流。在之前的研究基础上,通过增加一层具有大氧气离子迁移势垒的AlOy缓冲层,可以限制开关作用在活性氧化物中,进一步提高设备的均匀性。 4. 交叉点阵列(Cross-Point Array):一种存储器阵列结构,适用于高密度集成。这种结构的特点是每个存储单元都与两个交叉的线路相连,相邻单元共享一个选择器,从而实现密度最大化。最理想的单元面积是4F^2,其中F是特征尺寸。然而,由于基于金属氧化物的RRAM设备通常存在较大的变异性和分散性,这成为了其工业应用的障碍。 5. 多级数据存储能力(Multi-Level Data Storage):一些电阻开关存储器可以提供超过两个电阻状态,支持多级数据存储。这意味着每个存储单元可以存储更多的数据,增强了存储器的容量。 6. 稳健的可靠性特性(Robust Reliability Characteristics):对于存储器设备来说,可靠性至关重要。这意味着存储器在长期使用过程中,应保持其性能稳定,数据保持能力强,故障率低。 这些知识点涵盖了存储器的基本原理、关键的材料特性、制造技术以及器件结构设计等多个方面,对于深入理解高性能电阻开关存储器交叉点阵列的研究与应用具有重要意义。同时,文章中提到了制造过程和应用前景,说明了当前的研究成果在技术革新和产品应用层面具有实际价值,为存储器技术的发展方向提供了新的视角。

剩余6页未读,继续阅读

- 粉丝: 6

- 资源: 920

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- 微控制器固件包_STM32CubeG0_1741142084.zip

- 《ARM9嵌入式系统设计基础教程》第13章图形用户接口(GUI).ppt

- 《机械设计基础》课后习题答案

- C#调用Ni板卡进行实现采集任务(模拟量输入输出)示例2

- 《实验一 Java开发环境&语法基础》

- 2016级河南大学计算机与信息工程学院创新实践计划-消防机器人.zip

- Java课程设计-学生成绩管理系统-Swing+MySQL.zip

- 《AE影视后期特效制作实例教程》8-3++空中气流写字字帖.ppt

- Unwrap Pro是一个3ds Max插件,可以在产生低失真,无重叠,加权密度的UVs的同时展开网格,而不像3ds Max Peel命令,它产生具有高面积失真的重叠UV,UnwrapPro是非常快的

- 大二下SQL实验学生信息系统.zip

- macd指标算法 php语言编写 大智慧/同花顺 数据一致

- 2025修复版绿色全自适应php核心制作的邮编查询网整站源码带百万数据+定时触发更新

- 人工智能&深度学习:PyTorch 图像识别实战 - 卷积神经网络与模块应用资源(源码+数据集+说明资料)

- 《Java语言编程基础立体化实用教程》2-6+成绩增加和成绩修改窗体的实现.ppt

- ITECH艾德克斯交直流程控源使用手册

- 实时操作系统_FreeRTOS_内核组件_通用与特定_1741145229.zip

信息提交成功

信息提交成功