没有合适的资源?快使用搜索试试~ 我知道了~

The IEEE Journal of Solid-State Circuits publishes papers each month in the broad area of solid-state circuits with particular emphasis on transistor-level design of integrated circuits.

资源推荐

资源详情

资源评论

FEBRUARY 2020

VOLUME 55

NUMBER 2

IJSCBC

(ISSN 0018-9200)

REGULAR PAPERS

A 6.5–8.1-GHz Communication/Ranging VWB Transceiver for Secure Wireless Connectivity With Enhanced

Bandwidth Efficiency and Energy Detection ................ H. Song, D. Liu, Y. Zhang, W. Rhee, and Z. Wang

219

A CMOS 76–81-GHz 2-TX 3-RX FMCW Radar Transceiver Based on Mixed-Mode PLL Chirp Generator ..........

........................................ T. Ma, W. Deng, Z. Chen, J. Wu, W. Zheng, S. Wang, N. Qi, Y. Liu, and B. Chi

233

A Batteryless Padless Crystalless 116 μm ×116 μm “Dielet” Near-Field Radio With On-Chip Coil Antenna ........

........................................................ B. Zhao, N.-C. Kuo, B. Liu, Y.-A. Li, L. Iotti, and A. M. Niknejad

249

A Reconfigurable Spectrum-Compressing Receiver for Non-Contiguous Carrier Aggregation in CMOS SOI ..........

.................................................................. H. AlShammary, A. Hamza, C. Hill, an d J. F. Buckwalter

261

High Linearity Transmit Power Mixers Using Baseband Current Feedback ...... M. V. Praveen and N. Krishnapura 272

A CMOS Two-Element 170-GHz Fundamental-Frequency Transmitter With Direct RF-8PSK Modulation ............

.......................................................................................... P. Nazari, S. Jafarlou, and P. Heydari

282

An Event-Driven Quasi-Level-Crossing Delta Modulator Based on Residue Quantization ................................

................................................................................. H. Wang, F. Schembari, and R. B. Staszewski

298

A 12.5-MHz Bandwidth 77-dB SNDR SAR-Assisted Noise Shaping Pipeline ADC .......................................

.............................................................................. Y. Song, C.-H. Chan, Y. Zhu, and R. P. Martins

312

A Temperature-Stabilized Single-Channel 1-GS/s 60-dB SNDR SAR-Assisted Pipelined ADC With Dynamic

Gm-R-Based Amplifier ................................... W. Jiang, Y. Zhu, M. Zhang, C.-H. Chan, and R. P. Martins

322

A Discrete-Time Audio Modulator Using Dynamic Amplifier With Speed Enhancement and Flicker Noise

Reduction Techniques .......................................................... S.Ma,L.Liu,T.Fang,J.Liu,andN.Wu

333

A 76.6-dB-SNDR 50-MHz-BW 29.2-mW Multi-Bit CT Sturdy MASH With DAC Non-Linearity Tolerance ..........

...................................................... L. Qi, A. Jain, D. Jiang, S.-W. Sin, R. P. Martins, and M. Ortmanns

344

A Second-Order Purely VCO-Based CT ADC Using a Modified DPLL Structure in 40-nm CMOS ..............

............................................................ Y. Zhong, S. Li, X. Tang, L. Shen, W. Zhao, S. Wu, and N. Sun

356

A BJT-Based Temperature-to-Digital Converter With a ±0.25

◦

C3σ -Inaccuracy From −40

◦

Cto+180

◦

CUsing

Heater-Assisted Voltage Calibration .............................................. B. Yousefzadeh and K. A. A. Makinwa

369

A 0.3 lx–1.4 Mlx Monolithic Silicon Nanowire Light-to-Digital Converter With Temperature-Independent Offset

Cancellation ..................................................................................... C. Rhee, J. Park, and S. Kim

378

Combined In-Pixel Linear and Single-Photon Avalanche Diode Operation With Integrated Biasing for

Wide-Dynamic-Range Optical Sensing ........................................... H. Ouh, B. Shen, and M. L. Johnston

392

A 10-mA LDO With 16-nA IQ and Operating From 800-mV Supply .......... N. Adorni, S. Stanzione, and A. Boni 404

A 13.9-nA ECG Amplifier Achieving 0.86/0.99 NEF/PEF Using AC-Coupled OTA-Stacking ...........................

........................................................................................................ S. Mondal and D. A. Hall

414

A 951-fs

rms

Period Jitter 3.2% Modulation Range In-Band Modulation Spread-Spectrum Clock Generator ............

.............................................................. H. Sun, K. Sobue, K. Hamashita, T. Anand, and U.-K. Moon

426

A 32-Gb/s Simultaneous Bidirectional Source-Synchronous Transceiver With Adaptive Echo Cancellation

Techniques .......................... Y.-H. Fan, A. Kumar, T. Iwai, A. Roshan-Zamir, S. Cai, B. Sun, and S. Palermo

439

A 1.9-mW SVM Processor With On-Chip Active Learning for Epileptic Seizure Control ................................

..................................................................... S.-A. Huang, K.-C. Chang, H.-H. Liou, and C.-H. Yang

452

STICKER: An Energy-Efficient Multi-Sparsity Compatible Accelerator for Convolutional Neural Networks in 65-nm

CMOS ............................... Z. Yuan, Y. Liu, J. Yue, Y. Yang, J. Wang, X. Feng, J. Zhao, X. Li, and H. Yang

465

Enhanced Power and Electromagnetic SCA Resistance of Encryption Engines via a Security-Aware Integrated

All-Digital LDO ...... A. Singh, M. Kar, V. C. K. Chekuri, S. K. Mathew, A. Rajan, V. De, and S. Mukhopadhyay

478

Computationally Enabled Minimum Total Energy Tracking for a Performance Regulated Sub-Threshold Microprocessor

in 65-nm CMOS ................................................................ F. ur Rahman, R. Pamula, and V. S. Sathe

494

A 2.92-Gb/s/W and 0.43-Gb/s/MG Flexible and Scalable CGRA-Based Baseband Processor for Massive MIMO

Detection ...................................................................... G. Peng, L. Liu, S. Zhou, S. Yin, and S. Wei

505

378 IEEE JOURNAL OF SOLID-STATE CIRCUITS, VOL. 55, NO. 2, FEBRUARY 2020

A 0.3 lx–1.4 Mlx Monolithic Silicon Nanowire

Light-to-Digital Converter With

Temperature-Independent Offset Cancellation

Cyuyeol Rhee , Junyoung Park, Student Member, IEEE, and Suhwan Kim , Senior Member, IEEE

Abstract—This article presents a monolithic light-to-digital

converter (LDC) based on silicon nanowires. The silicon

nanowires are arranged in a configuration, which allows can-

cellation for the offset due to dark leakage current and facil-

itates system-level chopping of the signal chain, including the

nanowires. The readout integrated circuit (ROIC) has an ana-

log front end (AFE) with a resistive-feedback transimpedance

amplifier (TIA) to provide a constant voltage that strongly

biases the nanowires. A programmable-gain switched-capacitor

incremental delta–sigma analog-to-digital converter doubles the

output of the TIA and feeds a digital back end that provides

a decimated output. Finally, system-level chopping reduces the

residual offset and 1/f noise, and 50-/60-Hz rejection suppresses

interference from mains lighting. Fabricated in a 0.18-µmCMOS

process, the LDC has an input-referred current noise density

of 235 fA/

√

Hz, and a dynamic range of 106.7, from 0.3 lx to

1.4 Mlx. The offset from the nanowires and the AFE is reduced

to less than 30 µV and offset drift of 193 nV/°C in a temperature

range of −40 °C–85 °C. The AFE of the LDC draws 59.5 µAat

3.3 V, and the digital back end draws 8 µAat1.8V.

Index Terms— 1/f noise, 50-/60-Hz rejection, dark leakage

current, light-to-digital converter (LDC), programmable-gain

incremental delta–sigma analog-to-digital converter (ADC),

silicon nanowires, system-level chopping.

I. INTRODUCTION

L

IGHT sensor systems are used in a variety of applications,

such as light energy monitoring, proximity detection,

and non-invasive physiological monitoring [1]–[5]. A light

sensor system, which usually consists of a photodetector and

a readout integrated circuit (ROIC), must be able to handle

a wide range of illumination conditions from a very dark

environment (<1 lx) to bright sunlight (∼1 Mlx) [1], [2].

A light sensor system is usually based on a photodiode

(PD) [1]–[5]. This type of photodetector is widely used

because it has high linearity and is relatively insensitive to

changes in bias voltages. However, PDs require an illumination

area of several square millimeters due to their relatively

low photoresponsivity, making them less suitable for use in

Manuscript received March 15, 2019; revised July 5, 2019 and

September 16, 2019; accepted October 12, 2019. Date of publication

November 7, 2019; date of current version January 28, 2020. This article

was approved by Associate Editor David Stoppa. (Corresponding author:

Suhwan Kim.)

The authors are with the Department of Electrical and Computer Engi-

neering, Seoul National University, Seoul 08826, South Korea, and also

with the Inter-University Semiconductor Research Center (ISRC), College of

Engineering, Seoul 151-742, South Korea (e-mail: suhwan@snu.ac.kr).

Color versions of one or more of the figures in this article are available

online at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/JSSC.2019.2949257

ROICs [6]. Other types of photodetector can be integrated

into a system on a chip. For example, an array of single-

photon avalanche diodes (SPADs) with a very small area

(∼0.00072 mm

2

) and high photosensitivity has been integrated

into an ROIC [7]–[9]. However, SPADs require a high voltage

between 8 and 20 V, which involves an extra charge pump,

which increases power consumption [8]–[10], and the sys-

tem with SPADs provides a limited optical dynamic range

of 48 dB [8]. Silicon nanowires do not require high-voltage

biasing, high sensitivity to light and the high surface-to-

volume ratio [6], [11], [12], and, therefore, emerged as a very

promising photodetector.

Light falling on a silicon nanowire creates electron–hole

pairs, and thus, its resistance decreases [6]. This response

is monotonic, but the resulting photocurrent depends on the

voltage applied to the nanowire [6], [11]. A nanowire, which

is not illuminated at all, still has a finite resistance, and if

the voltage is applied, the current will flow. This is called the

dark leakage current. The equivalent resistance of a silicon

nanowire at a specific bias voltage varies with temperature,

even in very low illumination [14], [17], which means that

the offset arising from the dark leakage current is sensitive

to temperature. When silicon nanowires are integrated with

other circuits, this current can be affected by waste heat

from other circuits, as well as the ambient temperature. The

offsets produced not only by the dark leakage current but also

by the ROIC are generally undesirable and are cumbersome

when temperature changes because a one-time calibration is

not enough to eliminate offset errors across all temperature.

Therefore, these offsets must be suppressed over the operating

temperature range.

To overcome these issues, we present a monolithic light-

to-digital converter (LDC), which compensates for the offset

voltages generated by dark leakage current and ROIC, over

its entire temperature range. This LDC consists of a silicon

nanowire sensor (R

S

), a dark cell (R

D

), an analog front end

(AFE), a digital back end, and peripheral blocks. The AFE,

which largely determines the performance of the LDC, con-

sists of a resistive-feedback transimpedance amplifier (TIA)

and a programmable-gain switched-capacitor (SC) incremental

delta–sigma () analog-to-digital modulator. Within the

TIA, a chopping technique is combined with a ripple-reduction

loop (RRL) to achieve constant biasing of the sensor, low

1/ f noise corner, and a reduced offset. This TIA operates

in conjunction with system-level chopping, which takes place

0018-9200 © 2019 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission.

See http://www.ieee.org/publications_standards/publications/rights/index.html for more information.

RHEE et al.: 0.3 lx–1.4 Mlx MONOLITHIC SILICON NANOWIRE LDC WITH TEMPERATURE-INDEPENDENT OFFSET CANCELLATION 379

across the entire system, including the sensor, to eliminate

the offset due to dark leakage current and the ROIC, across

the operating temperature range. System-level chopping also

reduces the residual 1/ f noise and sensor bias voltage. This

eliminates the need for offset calibration when the sensor is

interfaced with the ROIC. A digital rejection filter notches out

50-/60-Hz noise from any mains light source.

The remainder of this article is organized as follows.

In Section II, we describe silicon nanowires. In Section III,

we introduce the LDC. Section IV is devoted to the details of

the TIA. In Section V, we introduce the programmable-gain

SC incremental analog-to-digital converter (ADC). Exper-

imental results are presented in Section VI. We draw conclu-

sions in Section VII.

II. S

ILICON NANOWIRESASALIGHT-SENSING ELEMENT

Silicon nanowires can be constructed by bottom–up or

top–down fabrication. Bottom–up fabrication is synthesis-

based, which is incompatible with the standard process of

CMOS ICs [15], [16]. In this case, nanowires and ICs must

be connected by wire bonding, resulting in a high packaging

cost. A sensing system created in this manner would be

large and noisy due to the parasitic capacitance formed by

the bonding process. An integrated configuration of silicon

nanowires can be produced by top–down fabrication, such as

photolithography and etching [6], [13]–[16].

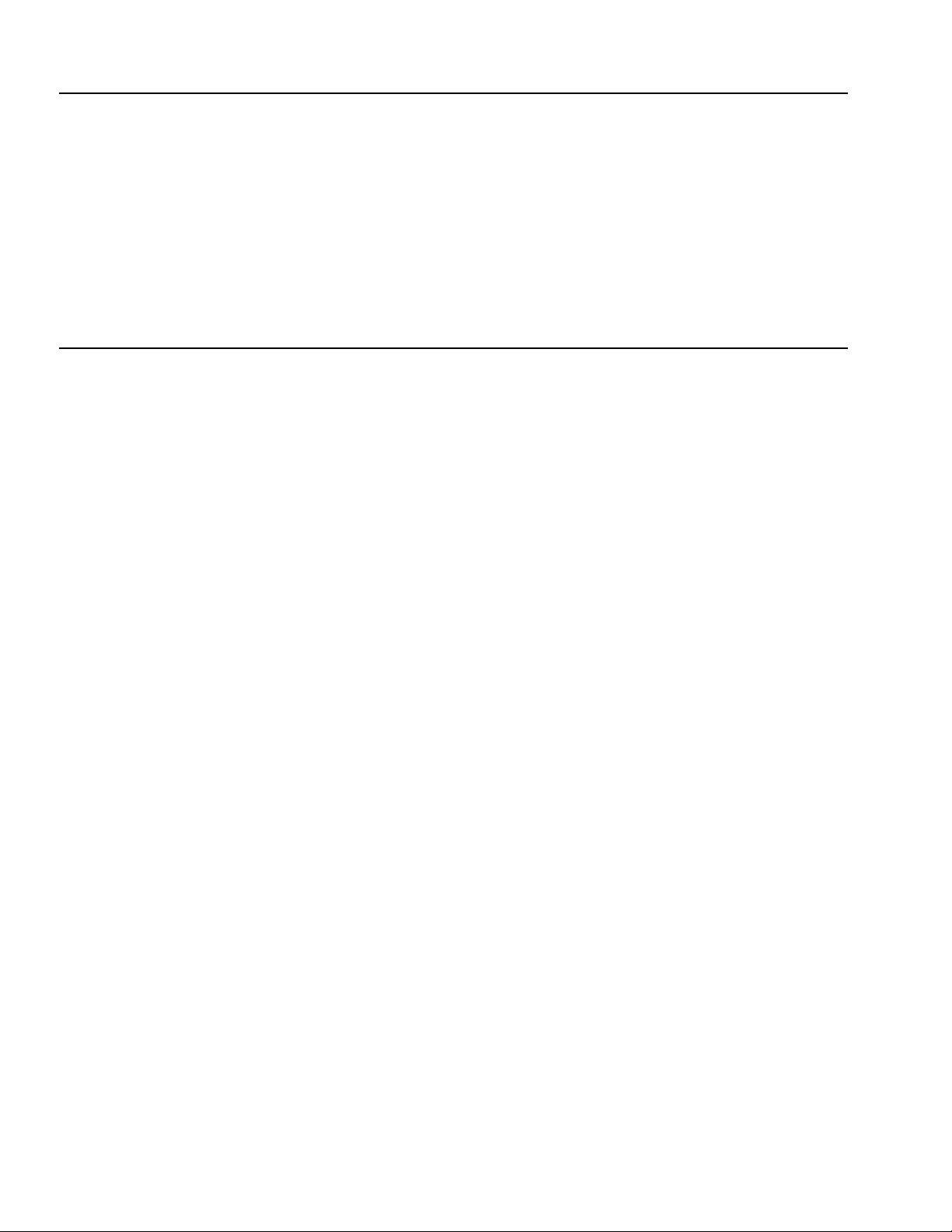

Within a CMOS standard process, silicon nanowires, such

as that shown in Fig. 1(a) and (b), can be produced by

the following fabrication process. A p-type substrate lightly

doped with boron is prepared, and thermal oxide is grown

by a wet oxidation process. Line patterns of 0.5 μmare

defined by a photolithography process, and rectangular sil-

icon columns are fabricated by silicon reactive ion etching

process. Afterward, a wet etching process using tetramethy-

lammonium hydroxide (TMAH) solution forms hour-glass-

shaped structures. In this process, anisotropic wet etching is

performed utilizing that the etch rate of (111)-plane is more

than one hundred times slower than that of the (100)-plane.

Then, the second wet oxidation process is performed to fabri-

cate triangular-shaped silicon nanowires by thermal oxidation.

Gaps between the silicon nanowires are filled with oxida-

tion layer by high-density plasma chemical vapor deposition

(HDPCVD). Silicon nanowires are covered with oxide and

nitride passivation layer. After fabrication of silicon nanowires,

CMOS circuits are processed. The CMOS process provides

four interconnect layers (metal 1 –metal 4). The dark cell is

shielded by placing the metals available in the CMOS process

on the top of the dark cell [18]–[22]. Fig. 1(c) is a scanning

transmission electron microscope (STEM) image of a silicon

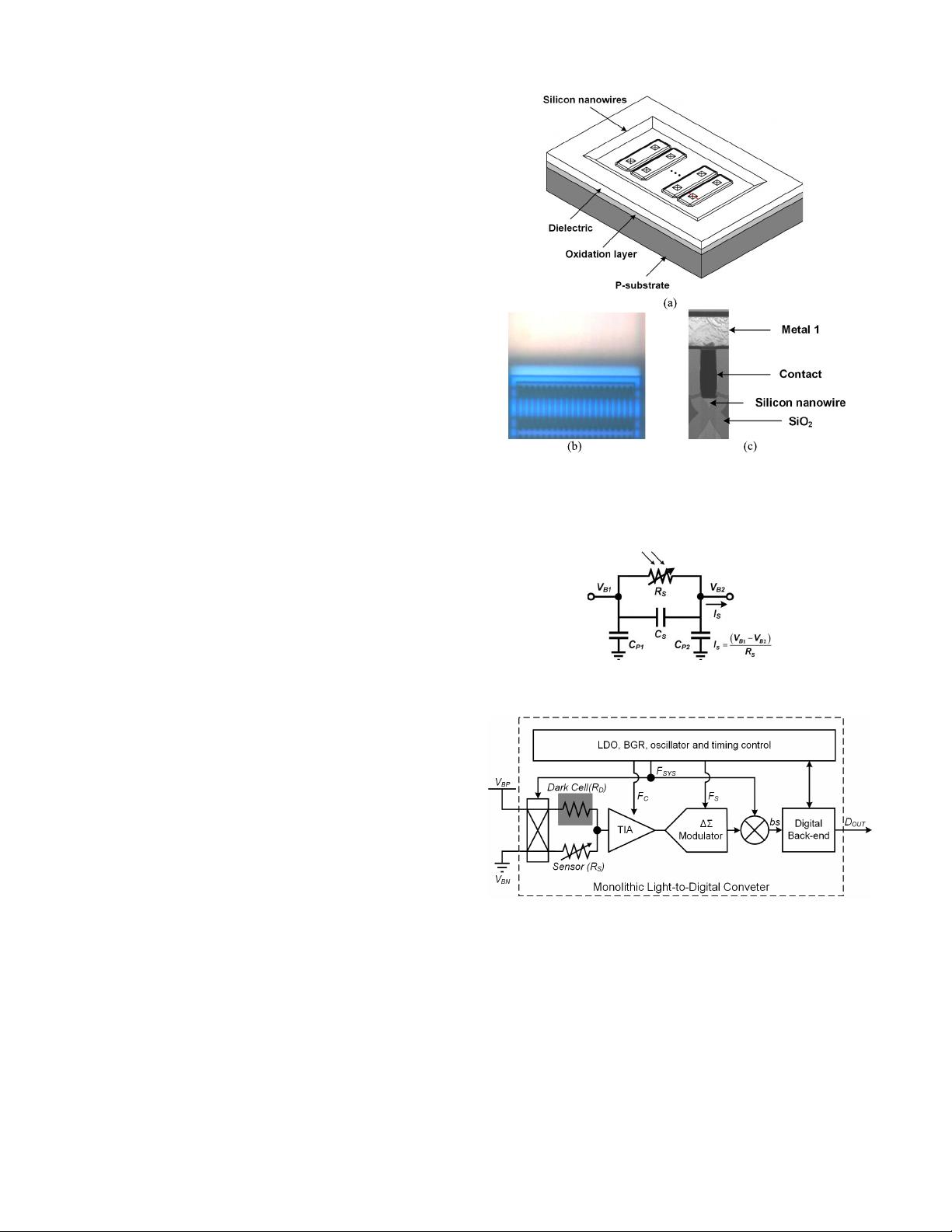

nanowire with a width of 300 nm. Fig. 2 is the equivalent

electrical model of the sensor, which is an array of silicon

nanowires. The model consists of an equivalent resistance R

S

,

a shunt capacitance C

S

, and two parasitic capacitances C

P1

and C

P2

due to interconnections to the terminals of the silicon

nanowires. Rs decreases from a few G down to 11 M as

the light intensity changes from 0 lx to 28 000 lx. C

S

can be

ignored in a relatively slow system, which is likely to have

Fig. 1. (a) Arrangement of CMOS-compatible silicon nanowires in an array.

Metal connections to contact holes are not shown. (b) Top view of an array of

silicon nanowires and the dark cell (white). (c) STEM image of the vertical

cross section view [dashed line in Fig. 1(a)] of a silicon nanowire.

Fig. 2. Electrical model of the silicon nanowire sensor.

Fig. 3. Monolithic silicon nanowire LDC.

a bandwidth below 10 Hz. On-chip integration of the sensor

and the ROIC can keep the values of C

P1

and C

P2

smaller

than a few hundred femtofarads.

III. M

ONOLITHIC LDC

The LDC shown in Fig. 3 consists of a silicon nanowire

sensor, a dark cell, a TIA, an incremental modulator,

a digital back end, and peripherals, such as a bandgap voltage

reference (BGR), a low-dropout (LDO) voltage regulator, and

an oscillator. The sensor R

S

is an array of silicon nanowires,

380 IEEE JOURNAL OF SOLID-STATE CIRCUITS, VOL. 55, NO. 2, FEBRUARY 2020

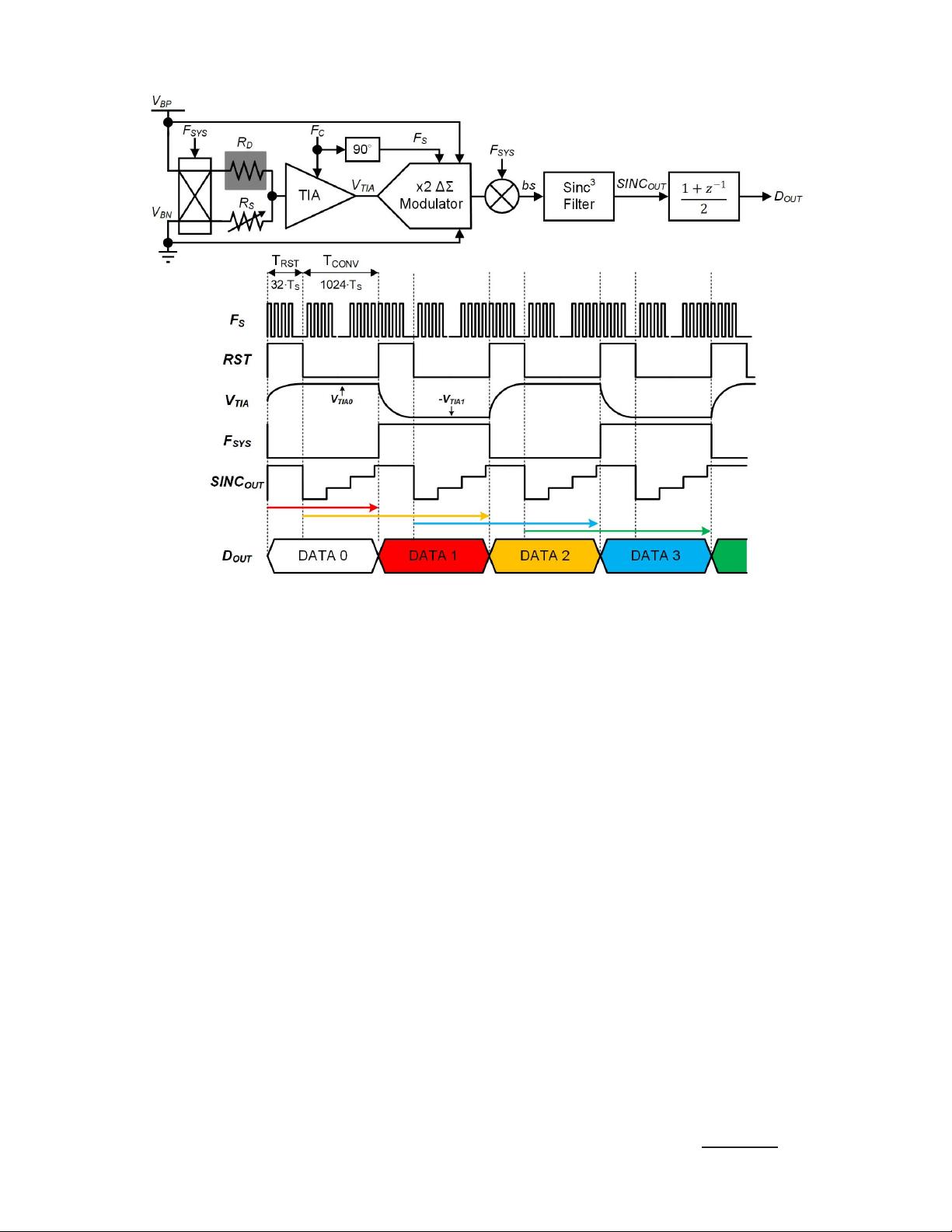

Fig. 4. Architecture of the analog front end and its timing diagram.

and the dark cell R

D

is a duplicate of the sensor, except that it

is covered and surrounded by metal layers. There is chopping

on the entire system from sensor bias voltages to the output

of the modulator by F

SYS

, and a decimation filter decimates

the modulator’s output bs and provides a robust rejection

capability. The decimated 18-bit digital codes D

OUT

are passed

through a serial communication in the digital back end. The

internal oscillator generates a 4-MHz clock signal for I

2

C and

SPI for serial communications. The clock generator receives an

86.4-kHz clock signal from the digital back end and generates

a 21.6-kHz clock signal F

C

for chopping the main amplifier

in the TIA and the RRL and 90° shifted sampling clock

signal F

S

for the modulator. A voltage V

BP

of 3.3 V

biases the sensor and provides the reference voltage to the

modulator. The BGR and LDO generate 1.8-V supply

for the digital circuits. A biasing circuit distributes a current

of 200 nA to bias amplifiers in the TIA and the modulator.

The system can save energy by going into sleep mode after a

conversion. The power-on reset (POR) puts the system into a

known state after wakeup.

The architecture of the AFE and its timing diagram are

shown in Fig. 4. The transimpedance gain of the TIA can

be controlled from 200 k to 10 M to accommodate the

wide dynamic range of ambient light while providing sub-lx

resolution. To achieve sub-lx resolution, the AFE requires the

transimpedance gain of 10 M and a 16.5-bit ADC, with

a single-ended operation of the TIA. This corresponds to a

noise voltage of 20 μV

rms

in the band of interest. The

modulator has a gain of 2, but its integrators are not saturated

at full-scale input because the output of the TIA and the

common-mode voltage V

CM

are connected to the differential

inputs of the modulator. The noise and offset of the readout IC

are primarily suppressed by a chopping scheme in the TIA.

The chopping ripple of the input stage is suppressed by a

continuous-time RRL to provide constant biasing of the sensor.

Asinc

3

filter is used for decimation, and a finite impulse

response filter provides a moving average of the SINC

OUT

signal for system-level chopping.

IV. I

MPLEMENTATION OF THE TIA

A. Sensor Configuration

In LDCs based on PDs, a dark PD is used to cancel a sensing

PD’s dark leakage current by connecting the sensing PD to one

input of a differential TIA and a dark PD to the other input,

as shown in Fig. 5(a) [18]–[22]. Since the equivalent resistance

of a PD is large and insensitive to light intensity, the circuit

in Fig. 5(a) does not affect the input common-mode voltage

of the TIA. However, if silicon nanowires are substituted

for the PDs, as shown in Fig. 5(b), the voltage across the

sensor will vary, changing the relationship between light

intensity and current. Fig. 5(c) shows the dc common-mode

equivalent circuit if the circuit described in Fig. 5(b). The input

common-mode voltage V

IN,dc

of the amplifier would vary as

follows:

V

IN,DC

= V

TIACOM

·

R

P

R

P

+ R

F

/2

(1)

剩余302页未读,继续阅读

资源评论

netshell

- 粉丝: 11

- 资源: 185

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

资源上传下载、课程学习等过程中有任何疑问或建议,欢迎提出宝贵意见哦~我们会及时处理!

点击此处反馈

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功