1

Sensorless Field Oriented Control of 3-Phase

Permanent Magnet Synchronous Motors

with CLA

Authors: Bilal Akin, Manish Bhardwaj

Texas Instruments, Inc.

C2000 Systems and Applications

2

Contents

Introduction ................................................................................................................................................ 3

PMSM Motors ............................................................................................................................................ 3

Field Oriented Control ............................................................................................................................... 5

Benefits of 32-bit C2000 Controllers for Digital Motor Control ............................................................... .11

TI Motor Control Literature and DMC Library .......................................................................................... 12

System Overview ..................................................................................................................................... 13

Hardware Configuration ........................................................................................................................... 17

Software Setup Instructions to Run HVPMSM_Sensorless_CLA Project ............................................... 20

Incremental System Build ........................................................................................................................ 21

Abstract

This application note presents a solution to control a permanent magnet synchronous motor (PMSM)

using the Control Law Accelerator (CLA) which is a small foot print co processor present which is

present on some of the microcontrollers from the C2000 family of MCU. TMS320F2803x devices are

part of the family of C2000 microcontrollers which enable cost-effective design of intelligent controllers

for three phase motors by reducing the system components and increase efficiency. With these devices

it is possible to realize far more precise digital vector control algorithms like the Field Orientated Control

(FOC). This algorithm’s implementation is discussed in this document. The FOC algorithm maintains

efficiency in a wide range of speeds and takes into consideration torque changes with transient phases

by processing a dynamic model of the motor. Among the solutions proposed are ways to eliminate the

phase current sensors and use an observer for speed sensorless control.

This application note covers the following:

A theoretical background on field oriented motor control principle.

Incremental build levels based on modular software blocks

Experimental results

3

Introduction

A brushless Permanent Magnet Synchronous motor (PMSM) has a wound stator, a permanent magnet

rotor assembly and internal or external devices to sense rotor position. The sensing devices provide

position feedback for adjusting frequency and amplitude of stator voltage reference properly to maintain

rotation of the magnet assembly. The combination of an inner permanent magnet rotor and outer

windings offers the advantages of low rotor inertia, efficient heat dissipation, and reduction of the motor

size. Moreover, the elimination of brushes reduces noise, EMI generation and suppresses the need of

brushes maintenance.

This document presents a solution to control a permanent magnet synchronous motor using the

TMS320F2803x. This new family of DSPs enables cost-effective design of intelligent controllers for

brushless motors which can fulfill enhanced operations, consisting of fewer system components, lower

system cost and increased performances. The control method presented relies on the field orientated

control (FOC). This algorithm maintains efficiency in a wide range of speeds and takes into

consideration torque changes with transient phases by controlling the flux directly from the rotor

coordinates. This application report presents the implementation of a control for sinusoidal PMSM

motor. The sinusoidal voltage waveform applied to this motor is created by using the Space Vector

modulation technique. Minimum amount of torque ripple appears when driving this sinusoidal BEMF

motor with sinusoidal currents.

Permanent Magnet Motors

There are primarily two types of three-phase permanent magnet synchronous motors (PMSM). One

uses rotor windings fed from the stator and the other uses permanent magnets. A motor fitted with rotor

windings, requires brushes to obtain its current supply and generate rotor flux. The contacts are made

of rings and have any commutator segments. The drawbacks of this type of structure are maintenance

needs and lower reliability. Replacing the common rotor field windings and pole structure with

permanent magnets puts the motor into the category of brushless motors. It is possible to build

brushless permanent magnet motors with any even number of magnet poles. The use of magnets

enables an efficient use of the radial space and replaces the rotor windings, therefore suppressing the

rotor copper losses. Advanced magnet materials permit a considerable reduction in motor dimensions

while maintaining a very high power density.

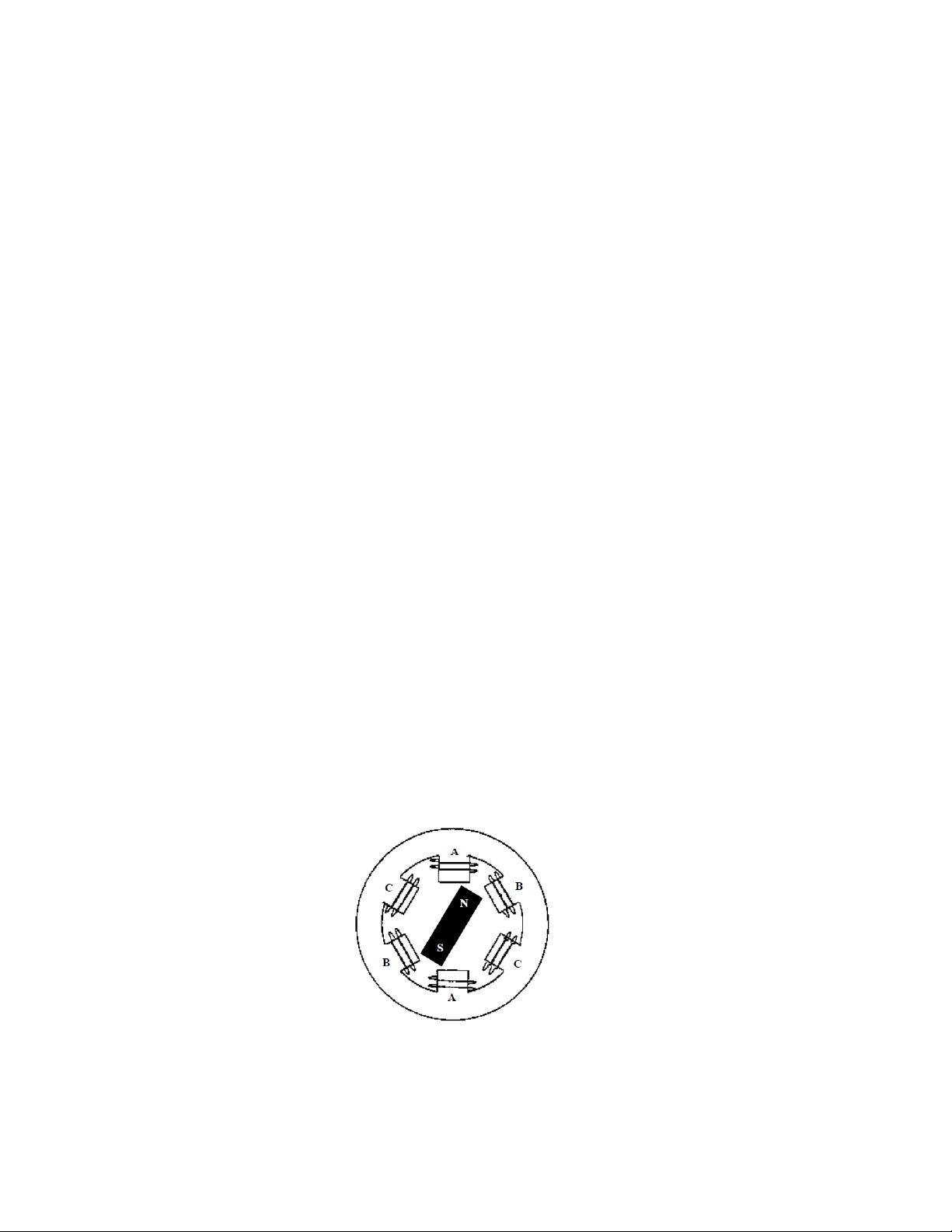

Fig. 1 A three-phase synchronous motor with a one permanent magnet pair

pole rotor

4

Synchronous Motor Operation

Synchronous motor construction: Permanent magnets are rigidly fixed to the rotating axis to create a

constant rotor flux. This rotor flux usually has a constant magnitude. The stator windings when

energized create a rotating electromagnetic field. To control the rotating magnetic field, it is

necessary to control the stator currents.

The actual structure of the rotor varies depending on the power range and rated speed of the

machine. Permanent magnets are suitable for synchronous machines ranging up-to a few Kilowatts.

For higher power ratings the rotor usually consists of windings in which a DC current circulates. The

mechanical structure of the rotor is designed for number of poles desired, and the desired flux

gradients desired.

The interaction between the stator and rotor fluxes produces a torque. Since the stator is firmly

mounted to the frame, and the rotor is free to rotate, the rotor will rotate, producing a useful

mechanical output.

The angle between the rotor magnetic field and stator field must be carefully controlled to produce

maximum torque and achieve high electromechanical conversion efficiency. For this purpose a fine

tuning is needed after closing the speed loop using sensorless algorithm in order to draw minimum

amount of current under the same speed and torque conditions.

The rotating stator field must rotate at the same frequency as the rotor permanent magnetic field;

otherwise the rotor will experience rapidly alternating positive and negative torque. This will result in

less than optimal torque production, and excessive mechanical vibration, noise, and mechanical

stresses on the machine parts. In addition, if the rotor inertia prevents the rotor from being able to

respond to these oscillations, the rotor will stop rotating at the synchronous frequency, and respond

to the average torque as seen by the stationary rotor: Zero. This means that the machine experiences

a phenomenon known as ‘pull-out’. This is also the reason why the synchronous machine is not self

starting.

The angle between the rotor field and the stator field must be equal to 90º to obtain the highest

mutual torque production. This synchronization requires knowing the rotor position in order to

generate the right stator field.

The stator magnetic field can be made to have any direction and magnitude by combining the

contribution of different stator phases to produce the resulting stator flux.

Fig. 2 The interaction between the rotating stator flux, and the rotor flux produces a torque

which will cause the motor to rotate.

5

Field Oriented Control

Introduction

In order to achieve better dynamic performance, a more complex control scheme needs to be applied,

to control the PM motor. With the mathematical processing power offered by the microcontrollers, we

can implement advanced control strategies, which use mathematical transformations in order to

decouple the torque generation and the magnetization functions in PM motors. Such de-coupled torque

and magnetization control is commonly called rotor flux oriented control, or simply Field Oriented

Control (FOC).

The main philosophy behind the FOC

In order to understand the spirit of the Field Oriented Control technique, let us start with an overview of

the separately excited direct current (DC) Motor. In this type of motor, the excitation for the stator and

rotor is independently controlled. Electrical study of the DC motor shows that the produced torque

and the flux can be independently tuned. The strength of the field excitation (i.e. the magnitude of

the field excitation current) sets the value of the flux. The current through the rotor windings determines

how much torque is produced. The commutator on the rotor plays an interesting part in the torque

production. The commutator is in contact with the brushes, and the mechanical construction is designed

to switch into the circuit the windings that are mechanically aligned to produce the maximum torque.

This arrangement then means that the torque production of the machine is fairly near optimal all the

time. The key point here is that the windings are managed to keep the flux produced by the rotor

windings orthogonal to the stator field.

AC machines do not have the same key features as the DC motor. In both cases we have only one

source that can be controlled which is the stator currents. On the synchronous machine, the rotor

excitation is given by the permanent magnets mounted onto the shaft. On the synchronous motor, the

only source of power and magnetic field is the stator phase voltage. Obviously, as opposed to the DC

motor, flux and torque depend on each other.

The goal of the FOC (also called vector control) on synchronous and asynchronous machine is to be

able to separately control the torque producing and magnetizing flux components. The control

technique goal is to (in a sense), imitate the DC motor’s operation. FOC control will allow us to

decouple the torque and the magnetizing flux components of stator current. With decoupled control of

the magnetization, the torque producing component of the stator flux can now be thought of as

independent torque control. To decouple the torque and flux, it is necessary to engage several

mathematical transforms, and this is where the microcontrollers add the most value. The processing

capability provided by the microcontrollers enables these mathematical transformations to be carried

out very quickly. This in turn implies that the entire algorithm controlling the motor can be executed at a

fast rate, enabling higher dynamic performance. In addition to the decoupling, a dynamic model of the

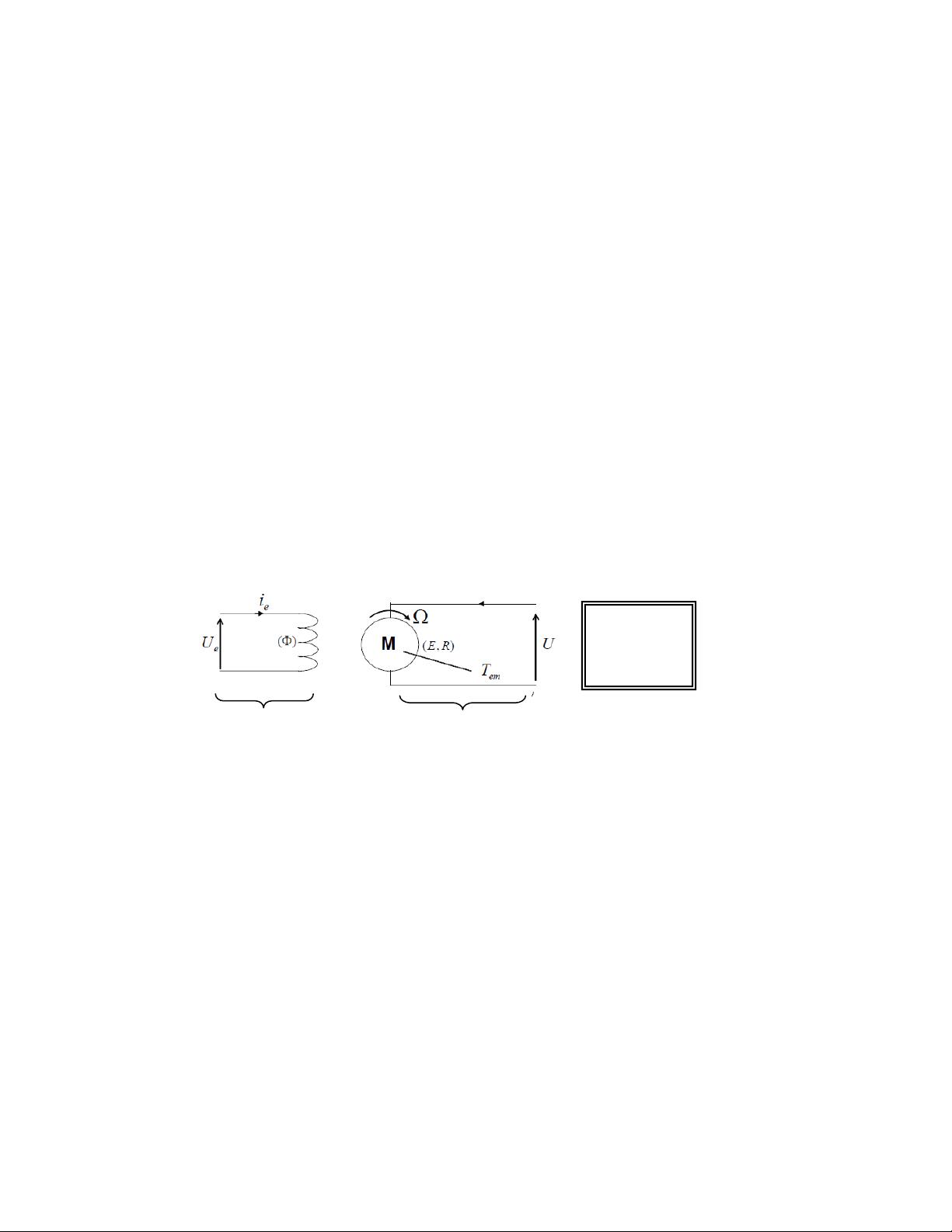

Fig 3. Separated excitation DC motor model, flux and torque are independently controlled

and the current through the rotor windings determines how much torque is produced.

)(

..

..

e

em

If

KE

IKT

=Φ

ΩΦ=

Φ=

Inductor (field

excitation)

Armature Circuit