Time-Dependent Dynamics in

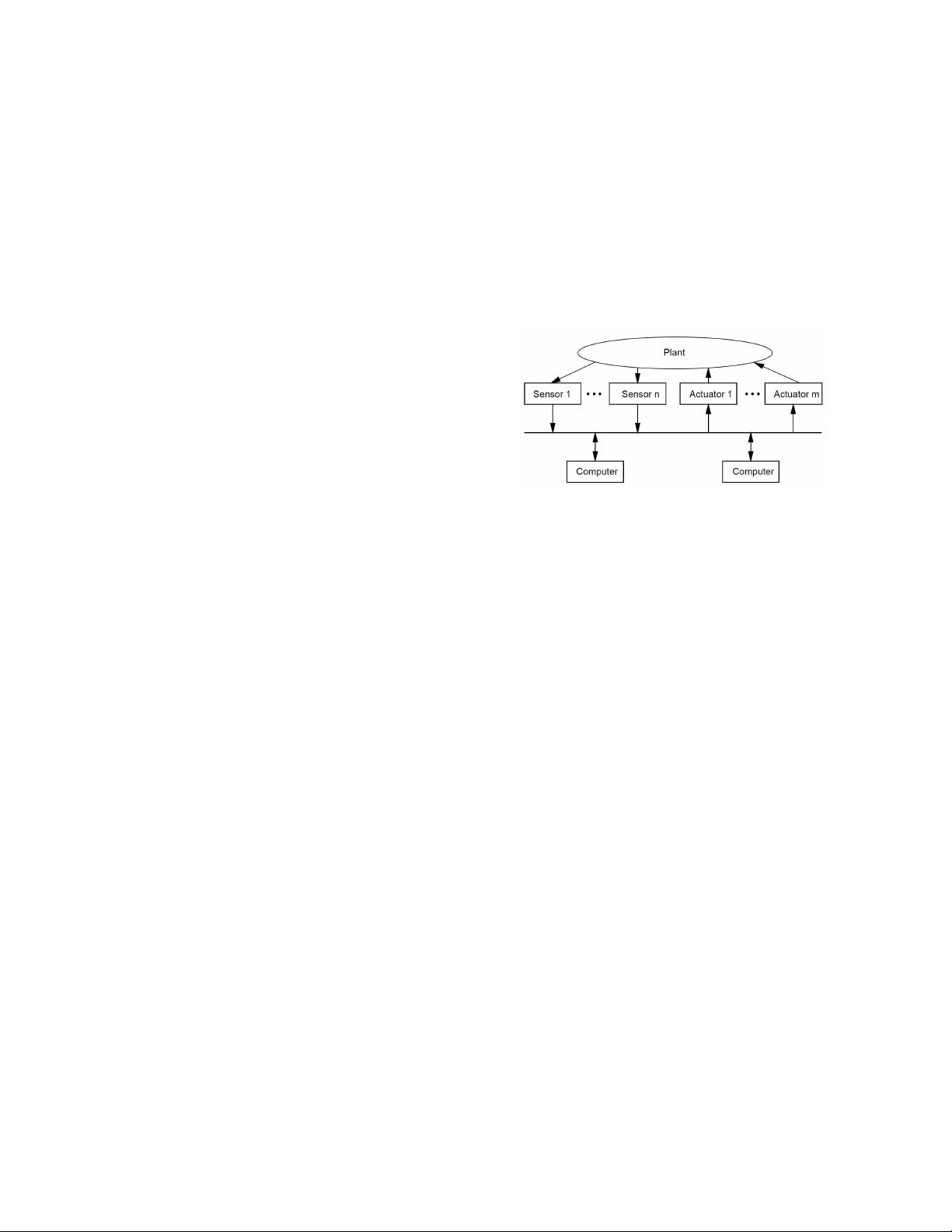

### 时间依赖动力学在网络化感知与控制系统中的应用 #### 概述 本文研究了网络化感知与控制系统(Networked Sensing and Control System, NSCS)的时间依赖动力学问题。NSCS是一种结合了网络化传感器与控制及执行单元的系统,用于控制物理环境。为了有效地利用感知信号与控制信号,这些信号必须及时传递。文章分析了NSCS的行为如何受到网络实时服务的影响,并特别考虑了有效的采样周期范围与网络延迟对被控物理环境稳定性的影响。 #### 网络化感知与控制系统(NSCS) NSCS是将网络化传感器与控制和执行单元相结合来控制物理环境的一种系统。它广泛应用于工业自动化、分布式仪器等领域。在NSCS中,如果传感器数据或控制指令传递得过晚,则这些数据可能变得无效甚至有害,可能导致物理环境的不稳定、不安全以及性能下降。因此,NSCS的工作原理高度依赖于网络的实时行为。 #### 实时网络行为的重要性 由于NSCS的关键任务性质,实时网络行为对其至关重要。网络延迟和丢包等时间依赖性因素直接影响系统的稳定性和安全性。因此,了解和建模这些动态变化对于设计可靠的NSCS系统极为重要。 #### 分析方法 - **系统建模**:首先介绍本文所分析的NSCS模型。该模型通常包括传感器、控制器、执行器以及连接这些组件的网络。 - **网络特性**:重点讨论了网络的实际行为,特别是时间变化的网络延迟和丢包率。这些特性直接影响到控制信号的有效传输。 - **稳定性分析**:研究了有效采样周期和网络延迟的范围,这些参数决定了被控物理环境的稳定性。文章探讨了实际稳定性区域如何受到包延迟和丢包的时间依赖行为的影响。 - **仿真结果**:通过仿真研究了不同网络条件下的系统行为,验证了理论分析的结果。 #### 时间依赖性因素 - **包延迟**:网络中的数据包从源到目的地的时间延迟会随时间而变化,这会影响控制信号的时效性。 - **丢包率**:网络中数据包丢失的概率也会随时间变化,这可能导致控制信号无法按时到达。 #### 稳定性区域分析 - **理想稳定性区域**:基于对丢包和延迟过程的综合视图得出的稳定性区域。 - **实际稳定性区域**:考虑到包延迟和丢包的时间依赖行为后得到的实际稳定性区域,与理想情况可能存在显著差异。 #### 研究贡献 本文通过分析和模拟一个代表性的物理系统在简单拓扑上的行为,探究了时间变化的网络动态如何被纳入控制理论模型中。重点关注了分组交换传感网络,因为这种网络在工业自动化中广泛应用且分析更为简便。 #### 结论 通过本文的研究可以得出,为了确保NSCS的有效运行,需要深入理解并处理网络中的时间依赖性因素,如包延迟和丢包率的变化。实际稳定性区域受到这些因素的影响,与理想情况下的稳定性区域可能有所不同。未来的研究将进一步探索如何优化网络设计和控制策略,以应对这些挑战,提高NSCS的整体性能和可靠性。

剩余7页未读,继续阅读

- 粉丝: 0

- 资源: 2

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- ASP.NET《数据库原理及应用技术》课程指导平台的开发(源代码+论文)(20248c).7z

- comsol 拓扑优化,流动传热拓扑优化,流固耦合拓扑优化 标准方程模型,温度,耗散双目标拓扑优化,材料插值模型,归一化

- 汽车基于动力学模型MPC的加入规划层的轨迹跟踪避障控制 双障碍物避障

- 目标检测(航拍)配网缺陷检测数据集1787张3类YOLO+VOC格式.zip

- Comsol隧道围岩流固耦合 1主题:岩溶隧道突水渗流和损伤 2内容:mph文件、力学参数文件,围岩损伤课题参考文献(500M) 3备注:看懂每一步建模过程,特别注意研究模态及matlab和comso

- 目标检测-6种常见宠物狗狗类别识别数据集1257张YOLO+VOC格式(已增强).zip

- 调频电路设计 Multisim.13

- 石英晶体振荡电路设计 Multisim.13

- 毕设-php电子商务网站-毕业设计3.zip

- 毕设-PHP基于Linux的远程管理系统客户端的实现(源代码+lw)6.zip

- 毕设-php进销存管理系统-毕业设计9.zip

- 毕设-php酒店预订管理系统-毕业设计pc10.zip

- 毕设-基于PHP的网上书店的设计(lw)20.zip

- 【未发表】基于海洋捕食者优化算法MPA优化宽度学习BLS实现光伏数据预测算法研究附Matlab代码.rar

- 【未发表】基于海洋捕食者优化算法MPA优化集成学习结合核极限学习机KELM-Adaboost实现风电数据时序预测算法研究附Matlab代码.rar

- 【未发表】基于海洋捕食者优化算法MPA优化集成学习结合鲁棒极限学习机RELM-Adaboost实现负荷数据回归预测算法研究附Matlab代码.rar

信息提交成功

信息提交成功