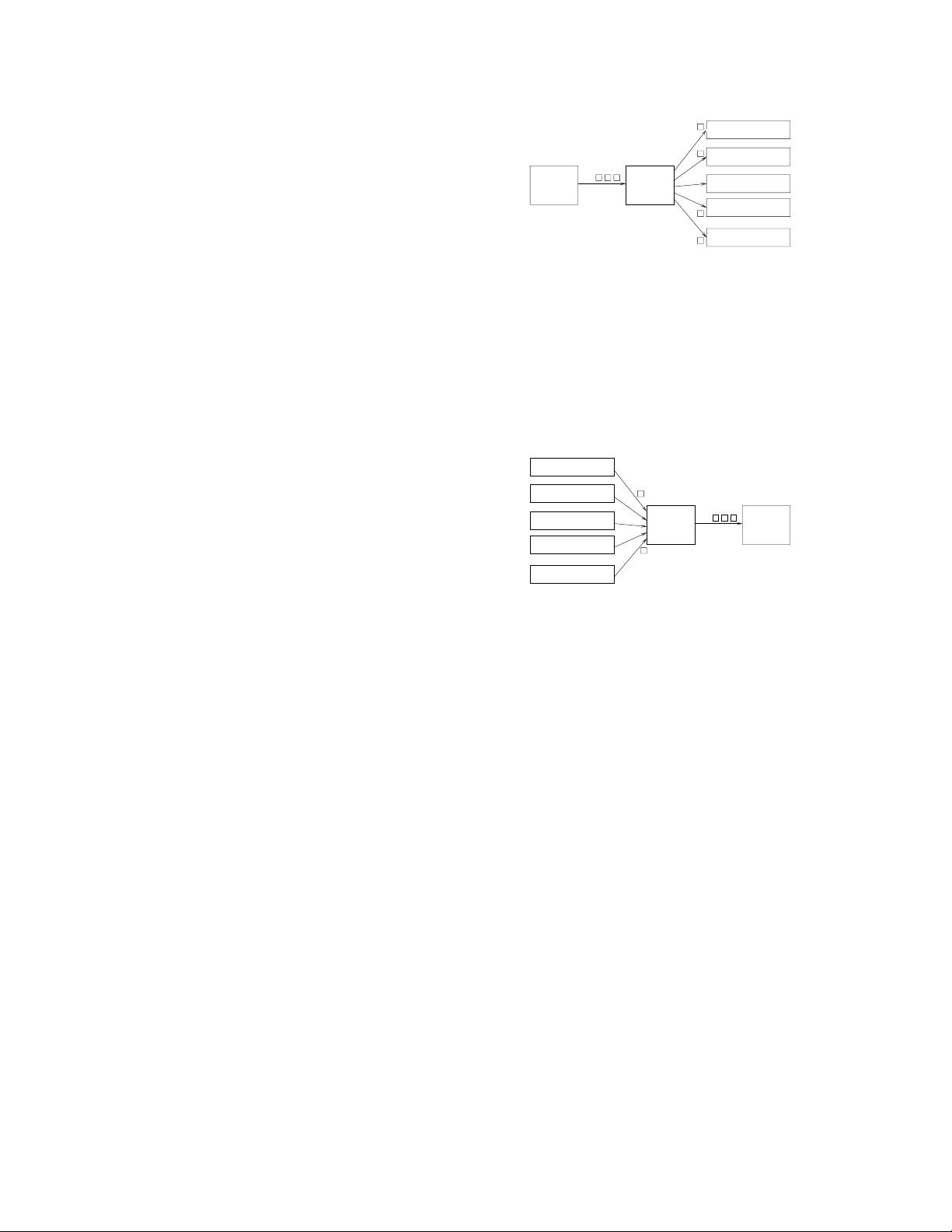

PWM

nSLEEP

nFAULT

2.7 to 10.8 V

Controller

M

+ t

+ t

DRV8833

Stepper or

Brushed DC

Motor Driver

1.5 A

1.5 A

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

Reference

Design

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

English Data Sheet: SLVSAR1

DRV8833

ZHCS016E –JANUARY 2011–REVISED JULY 2015

DRV8833 双双路路 H 桥桥电电机机驱驱动动器器

1

1 特特性性

1

• 双路 H 桥电流控制电机驱动器

– 可以驱动两部直流电机或一部步进电机

– 低金属氧化物半导体场效应晶体管 (MOSFET)

导通电阻:高侧 (HS) + 低侧 (LS) 360mΩ

• 输出电流(V

M

= 5V,25°C 时)

– 采用 PWP/RTY 封装:每条 H 桥的 RMS 电流

为 1.5A,峰值电流为 2A

– 采用 PW 封装:每条 H 桥的 RMS 电流为

500mA,峰值电流为 2A

• 可以将输出并联,以实现

– 3A RMS 电流、4A 峰值电流(PWP 和 RTY 封

装)

– 1A RMS 电流、4A 峰值电流(PW 封装)

• 宽电源电压范围:

2.7V 至 10.8V

• PWM 绕组电流调节/电流限制

• 耐热增强型表面贴装封装

2 应应用用

• 电池供电式玩具

• 服务点 (POS) 打印机

• 视频安保摄像机

• 办公自动化设备

• 游戏机

• 机器人

3 说说明明

DRV8833器件为玩具、打印机及其他机电一体化应用

提供了一款双桥电机驱动器 解决方案。

该器件具有两个 H 桥驱动器,能够驱动两部直流刷式

电机、一部双极步进电机、多个螺线管或其他感性负

载。

每个 H 桥的输出驱动器模块由配置为 H 桥的 N 沟道功

率 MOSFET 组成,用于驱动电机绕组。每个 H 桥均

具备调节或限制绕组电流的电路。

该器件利用故障输出引脚实现内部关断功能,提供过流

保护、短路保护、欠压锁定和过热保护。另外,还提供

了一种低功耗休眠模式。

DRV8833 采用带有 PowerPAD™16 引脚超薄型四方

扁平无引线 (WQFN) 封装(环保型:符合 RoHS 标准

且不含锑/溴)。

器器件件信信息息

(1)

器器件件型型号号 封封装装 封封装装尺尺寸寸((标标称称值值))

DRV8833

TSSOP (16) 5.00mm x 4.40mm

HTSSOP (16) 5.00mm x 4.40mm

WQFN (16) 4.00mm x 4.00mm

(1) 要了解所有可用封装,请见数据表末尾的可订购产品附录。

简简化化电电路路原原理理图图

2

DRV8833

ZHCS016E –JANUARY 2011 –REVISED JULY 2015

www.ti.com.cn

Copyright © 2011–2015, Texas Instruments Incorporated

目目录录

1 特特性性.......................................................................... 1

2 应应用用.......................................................................... 1

3 说说明明.......................................................................... 1

4 修修订订历历史史记记录录 ........................................................... 2

5 Pin Configuration and Functions......................... 3

6 Specifications......................................................... 5

6.1 Absolute Maximum Ratings ...................................... 5

6.2 ESD Ratings ............................................................ 5

6.3 Recommended Operating Conditions....................... 5

6.4 Thermal Information.................................................. 5

6.5 Electrical Characteristics........................................... 6

6.6 Typical Characteristics.............................................. 7

7 Detailed Description.............................................. 8

7.1 Overview ................................................................... 8

7.2 Functional Block Diagram ......................................... 8

7.3 Feature Description................................................... 9

7.4 Device Functional Modes........................................ 11

8 Application and Implementation ........................ 12

8.1 Application Information............................................ 12

8.2 Typical Application .................................................. 12

9 Power Supply Recommendations...................... 14

9.1 Bulk Capacitance .................................................... 14

9.2 Power Supply and Logic Sequencing ..................... 14

10 Layout................................................................... 15

10.1 Layout Guidelines ................................................. 15

10.2 Layout Example .................................................... 15

10.3 Thermal Considerations........................................ 16

10.4 Power Dissipation ................................................. 16

11 器器件件和和文文档档支支持持 ..................................................... 17

11.1 文档支持................................................................ 17

11.2 社区资源................................................................ 17

11.3 商标 ....................................................................... 17

11.4 静电放电警告......................................................... 17

11.5 Glossary................................................................ 17

12 机机械械、、封封装装和和可可订订购购信信息息....................................... 17

4 修修订订历历史史记记录录

注:之前版本的页码可能与当前版本有所不同。

Changes from Revision D (March 2015) to Revision E Page

• 已更新

特性

分项,以包括其他封装规范................................................................................................................................... 1

• Added note back to Pin Functions regarding the different I/O types ..................................................................................... 3

• Corrected the device name and current regulation description in Overview ......................................................................... 8

• Corrected output current to 1.5-A RMS from 700-mA RMS .................................................................................................. 8

Changes from Revision C (January 2013) to Revision D Page

• 已添加 ESD

额定值表

,

特性 描述

部分,

器件功能模式

,

应用和实施

部分,

电源相关建议

部分,

布局

部分,

器件和文

档支持

部分以及

机械、封装和可订购信息

部分 ....................................................................................................................... 1

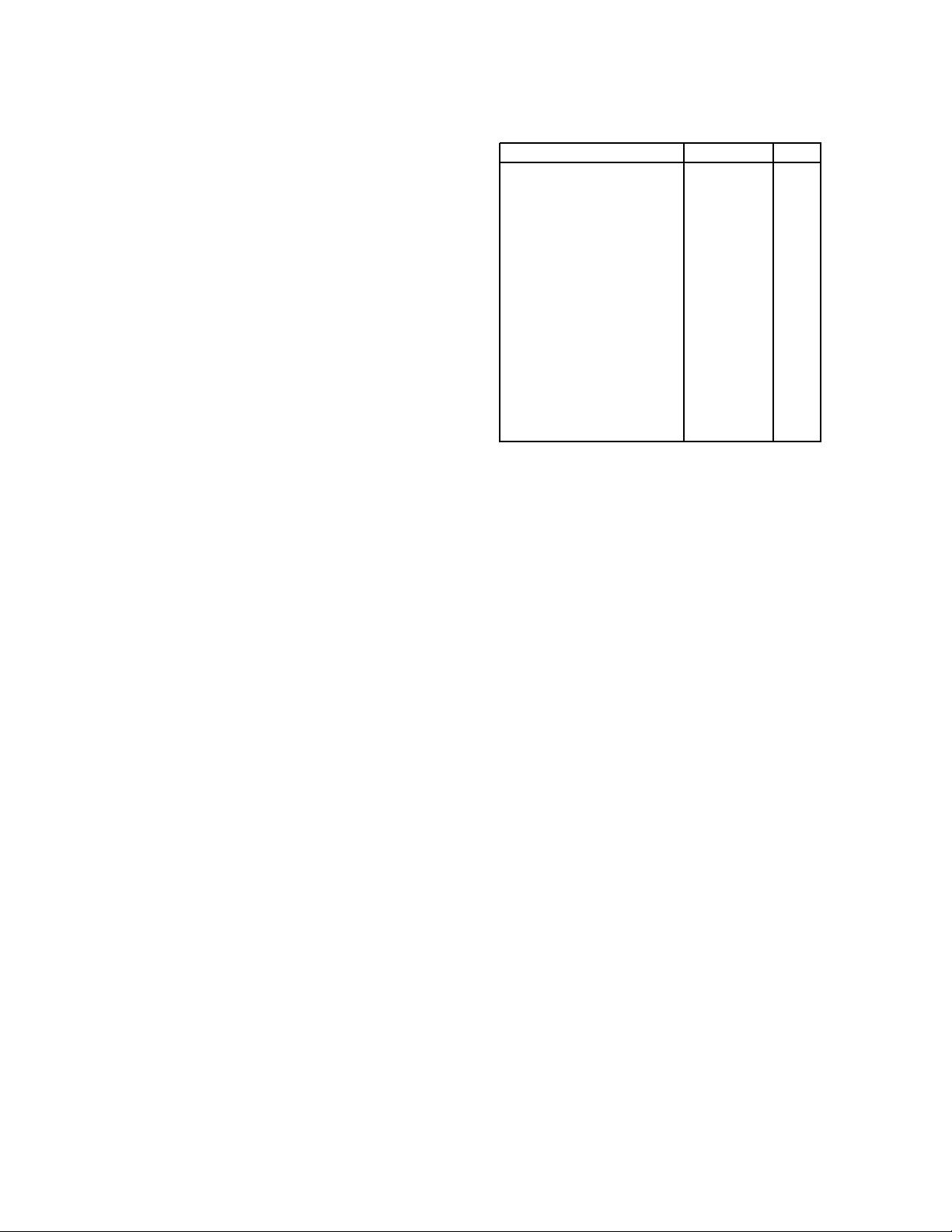

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

AIN1

AIN2

VINT

GND

VM

VCP

BIN2

BIN1

BOUT1

nFAULT

BOUT2

BISEN

AISEN

AOUT2

AOUT1

nSLEEP

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

GND

(PPAD)

AOUT1

nSLEEP

AIN1

AIN2

VINT

GND

VM

VCP

BIN1

BIN2

BOUT1

nFAULT

BOUT2

BISEN

AOUT2

AISEN

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

GND

(PPAD)

AIN1

AIN2

VINT

GND

VM

VCP

BIN2

BIN1

BOUT1

nFAULT

BOUT2

BISEN

AISEN

AOUT2

AOUT1

nSLEEP

3

DRV8833

www.ti.com.cn

ZHCS016E –JANUARY 2011–REVISED JULY 2015

Copyright © 2011–2015, Texas Instruments Incorporated

5 Pin Configuration and Functions

PWP Package

16-Pin HTSSOP

Top View

PW Package

16-Pin TSSOP

Top View

RTY Package

16-Pin WQFN

Top View

(1) I = Input, O = Output, OZ = Tri-state output, OD = Open-drain output, IO = Input/output

Pin Functions

PIN

I/O

(1)

DESCRIPTION

EXTERNAL COMPONENTS

OR CONNECTIONS

NAME WQFN

HTSSOP,

TSSOP

POWER AND GROUND

GND

11

PPAD

13 —

Device ground. HTSSOP package

has PowerPAD.

Both the GND pin and device PowerPAD

must be connected to ground.

VINT 12 14 — Internal supply bypass

Bypass to GND with 2.2-μF, 6.3-V

capacitor.

VM 10 12 — Device power supply

Connect to motor supply. A 10-µF

(minimum) ceramic bypass capacitor to

GND is recommended.

VCP 9 11 IO High-side gate drive voltage

Connect a 0.01-μF, 16-V (minimum) X7R

ceramic capacitor to VM.

CONTROL

AIN1 14 16 I Bridge A input 1

Logic input controls state of AOUT1.

Internal pulldown.

AIN2 13 15 I Bridge A input 2

Logic input controls state of AOUT2.

Internal pulldown.

BIN1 7 9 I Bridge B input 1

Logic input controls state of BOUT1.

Internal pulldown.

BIN2 8 10 I Bridge B input 2

Logic input controls state of BOUT2.

Internal pulldown.

nSLEEP 15 1 I Sleep mode input

Logic high to enable device, logic low to

enter low-power sleep mode and reset all

internal logic. Internal pulldown.

4

DRV8833

ZHCS016E –JANUARY 2011 –REVISED JULY 2015

www.ti.com.cn

Copyright © 2011–2015, Texas Instruments Incorporated

Pin Functions (continued)

PIN

I/O

(1)

DESCRIPTION

EXTERNAL COMPONENTS

OR CONNECTIONS

NAME WQFN

HTSSOP,

TSSOP

STATUS

nFAULT 6 8 OD Fault output

Logic low when in fault condition

(overtemperature, overcurrent)

OUTPUT

AISEN 1 3 IO Bridge A ground / I

SENSE

Connect to current sense resistor for bridge

A, or GND if current control not needed

BISEN 4 6 IO Bridge B ground / I

SENSE

Connect to current sense resistor for bridge

B, or GND if current control not needed

AOUT1 16 2 O Bridge A output 1

Connect to motor winding A

AOUT2 2 4 O Bridge A output 2

BOUT1 5 7 O Bridge B output 1

Connect to motor winding B

BOUT2 3 5 O Bridge B output 2

5

DRV8833

www.ti.com.cn

ZHCS016E –JANUARY 2011–REVISED JULY 2015

版权 © 2011–2015, Texas Instruments Incorporated

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

6 Specifications

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

(1)

MIN MAX UNIT

VM Power supply voltage –0.3 11.8 V

Digital input pin voltage –0.5 7 V

xISEN pin voltage –0.3 0.5 V

Peak motor drive output current Internally limited A

T

J

Operating junction temperature –40 150 °C

T

stg

Storage temperature –60 150 °C

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

6.2 ESD Ratings

VALUE UNIT

V

(ESD)

Electrostatic

discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all pins

(1)

±4000

V

Charged device model (CDM), per JEDEC specification JESD22-C101, all

pins

(2)

±1500

(1) R

DS(ON)

increases and maximum output current is reduced at VM supply voltages below 5 V.

(2) V

M

= 5 V, power dissipation and thermal limits must be observed.

6.3 Recommended Operating Conditions

T

A

= 25°C (unless otherwise noted)

MIN NOM MAX UNIT

V

M

Motor power supply voltage range

(1)

2.7 10.8 V

V

DIGIN

Digital input pin voltage range –0.3 5.75 V

I

OUT

RTY package continuous RMS or DC output current per bridge

(2)

1.5 A

(1) For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report, SPRA953.

6.4 Thermal Information

THERMAL METRIC

(1)

DRV8833

UNIT

PWP

(HTSSOP)

RTY

(WQFN)

PW

(TSSOP)

16 PINS 16 PINS 16 PINS

R

θJA

Junction-to-ambient thermal resistance 40.5 37.2 103.1 °C/W

R

θJC(top)

Junction-to-case (top) thermal resistance 32.9 34.3 38 °C/W

R

θJB

Junction-to-board thermal resistance 28.8 15.3 48.1 °C/W

ψ

JT

Junction-to-top characterization parameter 0.6 0.3 3 °C/W

ψ

JB

Junction-to-board characterization parameter 11.5 15.4 47.5 °C/W

R

θJC(bot)

Junction-to-case (bottom) thermal resistance 4.8 3.5 N/A °C/W