General

Specifications

<<Contents>> <<Index>>

EJX430A

Gauge Pressure Transmitter

Yokogawa Electric Corporation

2-9-32 Nakacho, Musashino-shi, Tokyo, 180-8750 Japan

Phone: 81-422-52-5690 Fax.: 81-422-52-2018

GS 01C25E01-01E

GS 01C25E01-01E

©Copyright Feb. 2004

4th Edition Jan. 2005

The high performance gauge pressure transmitter

EJX430A features single crystal silicon resonant

sensor and is suitable to measure liquid, gas, or

steam pressure. The EJX430A outputs a 4 to 20 mA

DC signal corresponding to the measured pressure. It

also features quick response, remote setup and

monitoring via BRAIN or HART communications, and

self-diagnostics. FOUNDATION Fieldbus protocol type

is also available.

All EJX series models in their standard configuration,

with the exception of the Fieldbus type, are certified by

TÜV as complying with SIL 2 for safety requirement.

STANDARD SPECIFICATIONS

Refer to GS 01C25T02-01E for Fieldbus communica-

tion type marked with “.”

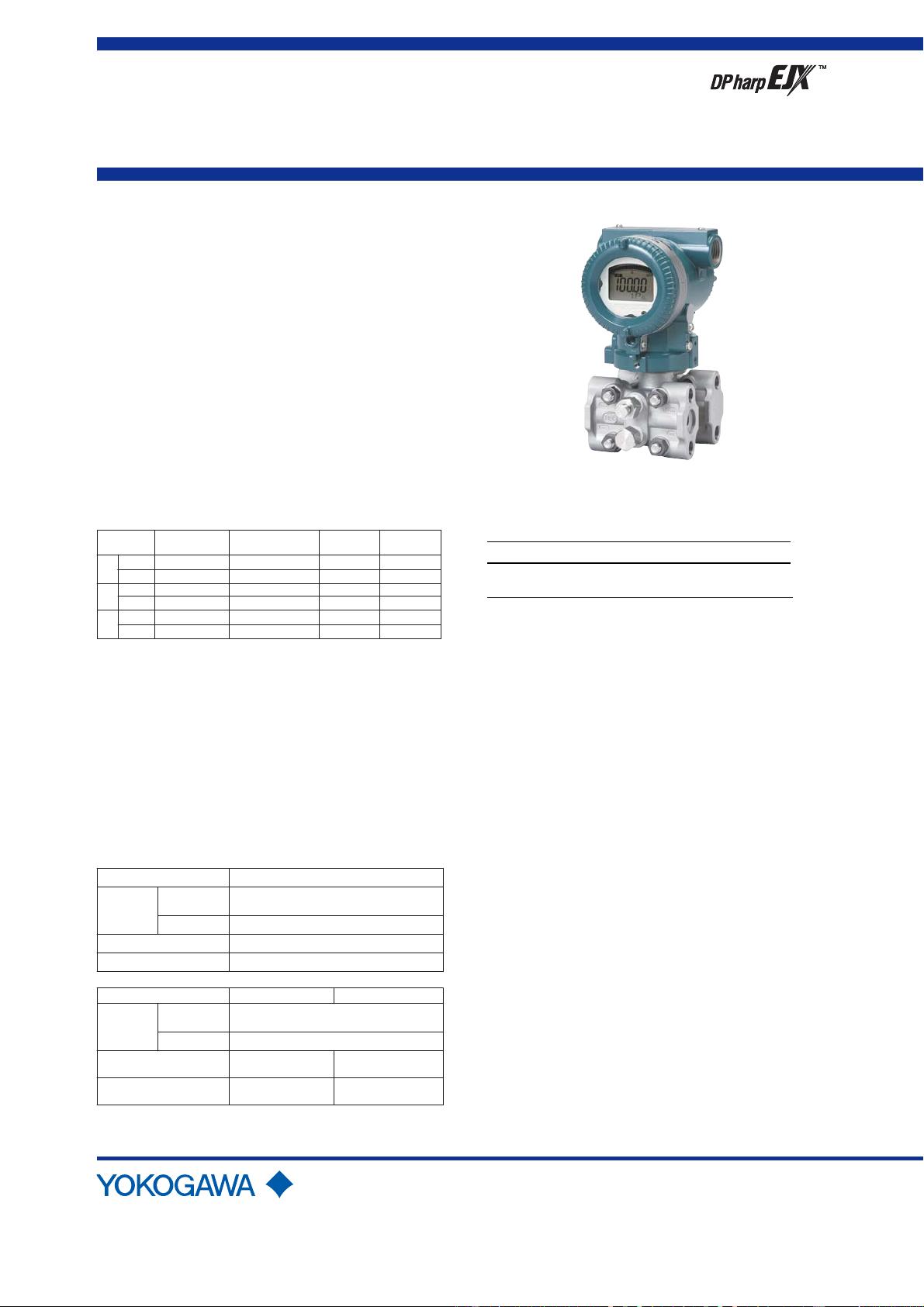

SPAN AND RANGE LIMITS

Measurement

Span/Range

H

A

B

2.5 to 500 kPa

– 0.1 to 3.5

–1 to 160

Span

Span

Span

Range

Range

Range

MPa

10 to 2000 inH

2

O

–400 to 2000 inH

2

O

–14.5 to 500

2.5 to 500

–100 to 500 kPa

0.0175 to 3.5

0.08 to 16

– 0.1 to 16

psi (/D1)

12 to 2300

–14.5 to 2300

bar(/D3)

0.025 to 5

–1 to 35

–1 to 5

0.175 to 35

0.8 to 160

–1 to 160

kgf/cm

2

(/D4)

0.025 to 5

–1 to 5

0.175 to 35

–1 to 35

0.8 to

1

60

T01E.EPS

PERFORMANCE SPECIFICATIONS

Zero-based calibrated span, linear output, wetted

parts material code ‘S’ and silicone oil, unless

otherwise mentioned.

For Fieldbus communication type, use calibrated

range instead of span in the following specifications.

Specification Conformance

EJX series ensures specification conformance to at

least ⫾3.

Reference Accuracy of Calibrated Span

(includes the effects of terminal-based linearity,

hysteresis, and repeatability)

Measurement span

Reference

accuracy

⫾0.04% of Span

⫾(0.005⫹0.0049 URL/Span)% of Span

H

T03E.EPS

X

X ⬎ span

X ⱕ span

URL (upper range limit)

70 kPa (280inH

2

O)

500 kPa (2000inH

2

O)

Measurement span

Reference

accuracy

⫾0.04% of Span

⫾(0.005⫹0.0035 URL/Span)% of Span

T02E.EPS

X

X ⬎ span

X ⱕ span

URL (upper range limit)

A

0.35 MPa

(50 psi)

1.6 MPa

(230 psi)

3.5 MPa

(500 psi)

16 MPa

(2300 psi)

B

Ambient Temperature Effects per 28˚C (50˚F)

Change

Capsule Effect

H ⫾(0.04% Span⫹0.0125% URL)

A, B ⫾(0.04% Span⫹0.009% URL)

Stability (All normal operating condition)

⫾0.1% of URL per 10 years

Power Supply Effects (Output signal code D and E)

⫾0.005% per Volt (from 21.6 to 32 V DC, 350 ⍀)

Vibration Effects

Less than 0.1% of URL when tested per the require-

ments of IEC60770-1 field or pipeline with high

vibration level (10-60 Hz, 0.21 mm peak to peak

displacement/60-2000 Hz 3g)

Mounting Position Effects

Rotation in diaphragm plane has no effect. Tilting up

to 90 degree will cause zero shift up to 0.4 kPa (1.6

inH

2

O) which can be corrected by the zero adjust-

ment.

Response Time (All capsules) “”

95 msec

When software damping is set to zero and including

dead time of 45 msec (nominal)

FUNCTIONAL SPECIFICATIONS

Output “”

Two wire 4 to 20 mA DC output with digital communi-

cations, linear or square root programmable. BRAIN

or HART FSK protocol are superimposed on the 4 to

20 mA signal.

Output range: 3.6 mA to 21.6 mA

Output limits conforming to NAMUR NE43 can be

pre-set by option code C2 or C3.

Failure Alarm (Output signal code D and E)

Output status at CPU failure and hardware error;

Up-scale: 110%, 21.6 mA DC or more (standard)

Down-scale: ⫺5%, 3.2 mA DC or less

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功