3.2.4. Other algorithms . . . . . . . .................................................................................. 64

3.3. Classification . . . . ................................................................................................ 65

3.3.1. Fuzzy clustering and neural network . . . . . . . .................................................................. 65

3.3.2. Rough sets. . . . . . . . . . . . . .................................................................................. 65

3.3.3. Support vector machines . .................................................................................. 65

4. Applications and case studies . . .......................................................................................... 65

4.1. On-line foreign fibers inspection with an AVI system . . . . . . ............................................................. 65

4.2. Multi-wavelength imaging system. . . . . . ............................................................................. 66

4.3. White light and UV light alternating system. . . . . . . . . . . . . . ............................................................. 66

4.4. X-ray imaging system . . . . . . . . . . . . . . . . ............................................................................. 66

4.5. Linear laser imaging system . . . . . . . . . . . ............................................................................. 67

4.6. Hyperspectral imaging system . . . . . . . . . ............................................................................. 67

5. Conclusions and future perspectives. . . . . . . . . . . . . . . . ....................................................................... 68

Acknowledgments . . . . . . . . . . . .......................................................................................... 68

References . .......................................................................................................... 68

1. Introduction

Cotton is an important resource related to numerous nations’

economies. Cotton processing and cotton spinning play an impor-

tant role in the Chinese national economy in particular. When har-

vesting, cotton is subject to contamination from numerous sources,

and a variety of foreign matter may become mixed with raw cotton

during cotton processing. Foreign matter, also called foreign mate-

rials, foreign contaminants, or cotton trash, refers to both botanical

trash and non-botanical trash which are inadvertently mixed with

cotton during picking, storing, drying, transporting, purchasing,

and processing (Yang et al., 2009a). Botanical trash includes hull,

leaf, bark, seed coat, etc. Non-botanical trash is also called foreign

fibers including hair, binding rope, plastic film, candy wrappers,

polypropylene twine, etc. Foreign matter is difficult to remove

and is easily broken into countless tiny parts that in turn increase

the breakability of cotton yarn and reduce the processing efficiency

and market value according to the cotton grading system. Foreign

matter also affects the quality of yarn and woven cloth as well as

the appearance of dyed cloth.

Conventional detection methods for foreign matter in cotton

have been performed by human workers, but most of these manual

inspections are time-consuming, inefficient, and have unverifiable

accuracy rates (Yang et al., 2009b; Li et al., 2006). The poor perfor-

mance of conventional detection methods and the bad effect of for-

eign matter on cotton industry have attracted great attention from

research institutes and cotton enterprises (Luo, 2007). Researchers

in China and abroad have been conducting research on foreign

matter detection for some time and have made significant pro-

gress. Several instrumental and sensory methods have been devel-

oped for the detection of foreign matter. The main detecting

principles can be categorized into three types: photoelectric detec-

tion, ultrasonic detection, and optical recognition (Shi, 2007).

Photoelectric detection detects foreign matter in cotton using a

phototransistor. It is used to identify foreign matter according to

the color variation between cotton and foreign matter. The method

is simple and has a low manufacturing cost. However, the detec-

tion rate is low due to the great attenuation of sensitivity and poor

stability of the phototransistor. It is also impossible to identify tiny

colored foreign matter as well as foreign matter that has a similar

brightness to cotton, such as white polypropylene (Chang, 2006).

Ultrasonic sensors transmit ultrasonic waves at the cotton and

receive the reflected information. Ultrasonic signals reflected by

objects with different densities are different. Therefore, the foreign

matter is identified by signal processing and comparison because

the signals reflected by foreign matter are typically stronger than

those reflected by cotton. It can be used to detect certain types of

foreign matter such as bulked paper strips, cloth strips, plastics,

etc. However, the speed of ultrasonic transmission is lower than

that of light, so the identification process is slow and sometimes

cannot be completed in the time allotted. In addition, ultrasonic

sensors are not able to identify small foreign matter (Chang, 2006).

Using a high-speed CCD or CMOS camera, the optical detection

method scans the surface of the cotton layer, and the images gen-

erated from the scanning signals are sent to a computer system for

processing. Both line scan cameras and area scan cameras can be

used, the first of which is more flexible and convenient. In contrast

to the two former methods, the advantage to optical detection is

that it can recognize small foreign matter in cotton and meet the

requirements of real time inspection. The only disadvantage is

the high cost of manufacturing the system (Chang, 2006). However,

with scientific and technological development, the cost will drop.

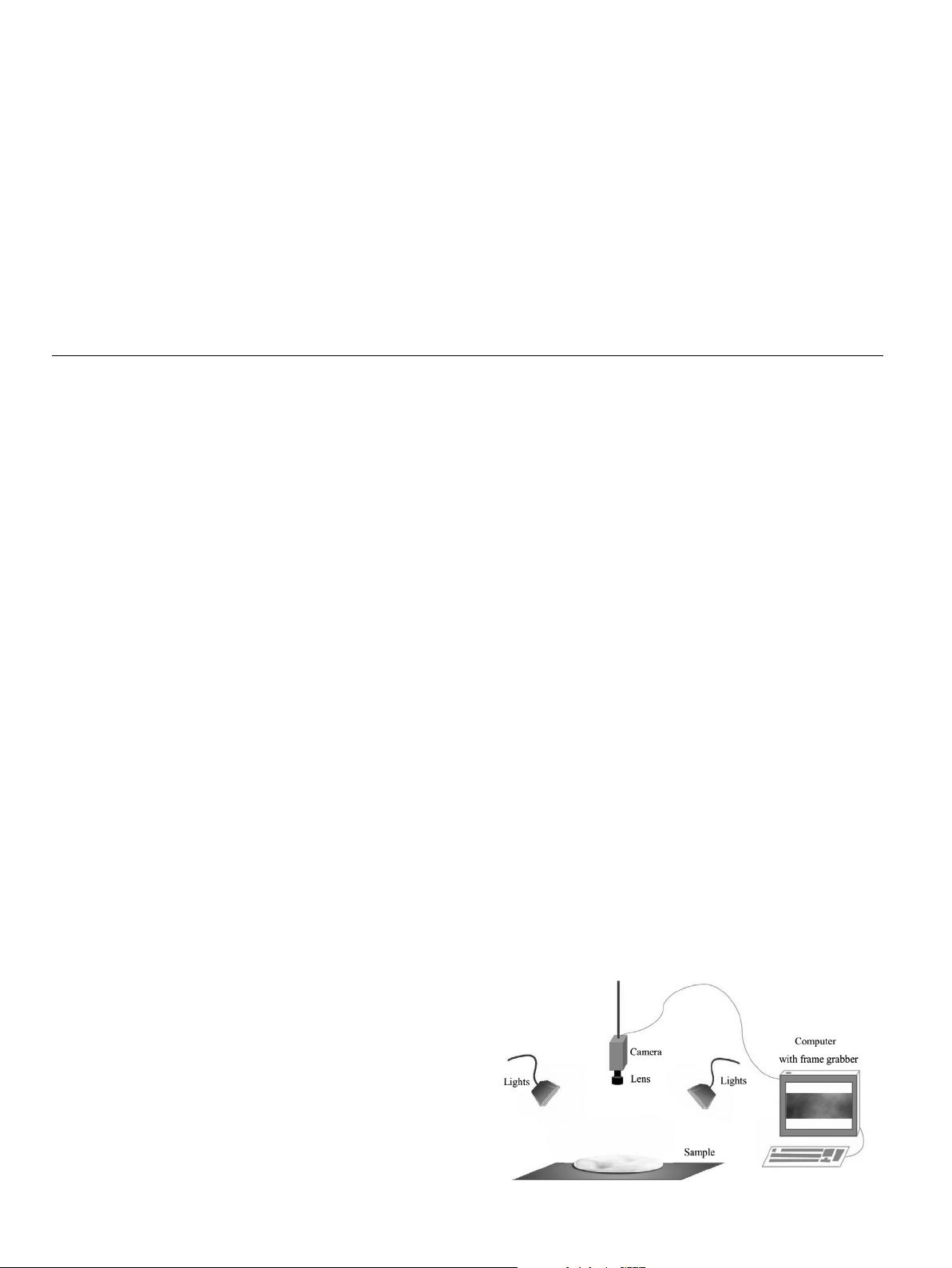

Based on the optical detection principle, computer vision tech-

niques have the advantages of cost effectiveness, consistency,

superior speed, objectiveness, and accuracy. With the advances

in hardware and software for digital image processing, automatic

inspection systems known as computer vision or machine vision,

mainly based on camera-computer technology, have been investi-

gated for the sensory analysis of agricultural and food products and

have been proven successful for the objective measurement of var-

ious agricultural products (Brosnan and Sun, 2004). Furthermore,

applications of these techniques have now expanded to various

areas such as medical diagnosis, automatic manufacturing and sur-

veillance, remote sensing, technical diagnostics, and autonomous

vehicle and robot guidance (Brosnan and Sun, 2002). In recent

years, computer vision systems have been applied to the textile

industries (Tantaswadi et al., 1999; Millman et al., 2001;

Abouelela et al., 2005) for inspection and/or removal of foreign

matter in cotton (Lieberman et al., 1998) and wool (Zhang et al.,

2005a–c; Su et al., 2006). These systems hold great potential for

the inspection of cotton foreign matter.

Fig. 1. Components of a basic computer vision system.

60 H. Zhang, D. Li / Computers and Electronics in Agriculture 109 (2014) 59–70

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功