没有合适的资源?快使用搜索试试~ 我知道了~

温馨提示

The minimally invasive surgery in spinal surgery has become increasingly popular in recent years as it reduces the chances of complications during post-operation. However, the procedure of spinal surgery is complicated and the surgical vision of minimally invasive surgery is limited. In order to increase the quality of percutaneous pedicle screw placement, the O-arm that is a mobile intraoperative imaging system is used to assist surgery. The robot navigation system combined with O-arm is also i

资源推荐

资源详情

资源评论

1

Content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence. Any further distribution

of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

Published under licence by IOP Publishing Ltd

1234567890 ‘’“”

ICMCE IOP Publishing

IOP Conf. Series: Journal of Physics: Conf. Series 1016 (2018) 012006 doi :10.1088/1742-6596/1016/1/012006

A spatial registration method for navigation system

combining O-arm with spinal surgery robot

H Bai

1,2

, G L Song

1

Y W Zhao

1

X Z Liu

1,2

and Y X Jiang

1

1

Shenyang Institute of Automation, Chinese Academy of Sciences, China.

2

Northeastern University, China.

Email: songgl@sia.cn

Abstract. The minimally invasive surgery in spinal surgery has become increasingly popular

in recent years as it reduces the chances of complications during post-operation. However, the

procedure of spinal surgery is complicated and the surgical vision of minimally invasive

surgery is limited. In order to increase the quality of percutaneous pedicle screw placement, the

O-arm that is a mobile intraoperative imaging system is used to assist surgery. The robot

navigation system combined with O-arm is also increasing, with the extensive use of O-arm.

One of the major problems in the surgical navigation system is to associate the patient space

with the intra-operation image space. This study proposes a spatial registration method of

spinal surgical robot navigation system, which uses the O-arm to scan a calibration phantom

with metal calibration spheres. First, the metal artifacts were reduced in the CT slices and then

the circles in the images based on the moments invariant could be identified. Further, the

position of the calibration sphere in the image space was obtained. Moreover, the registration

matrix is obtained based on the ICP algorithm. Finally, the position error is calculated to verify

the feasibility and accuracy of the registration method.

1. Introduction

In the past two decades, minimally invasive spine surgery (MISS) has been increasingly applied and

drawn much attention in the treatment of spinal disorders[1]. The development of image technology

has led to a more significant development of minimally invasive spinal surgery. Not only can MISS

minimize injury to paraspinal back muscles, connective tissues, and joints but it can also decrease the

amount of bleeding, infection, hospital stay, and postoperative pain[2].It decreases the incidence of

complications and approach-related morbidity and mortality associated with conventional open

surgery. The traditional open spine surgery has gradually been replaced with MISS. According to the

reports[1], the number of MISS conducted in 2010 accounted for 1/6 of the total number of all spine

surgeries in the United States and 1/3 in 2016, which is anticipated to be more than 1/2 in 2020.

Although MISS has the above advantages, it still faces to the following problems: (1) Surgeon's

surgical vision is limited. (2) With the increasing number of surgery, the surgeon's intra-operative

radiation exposure will accumulate. (3) The lack of surgical instrument's real-time position, reduces

the safety of surgical procedures.

In order to solve the above problems, some scholars have proposed that the robot navigation

technology could assist surgeons. A study assessed the feasibility and clinical value of robot assisted

navigation drilling for pedicle screw placement and the results confirmed that robot assisted surgery

could increase the quality of percutaneous pedicle screw placement[3]. The accuracy of guidance

systems in screw insertion procedures is particularly notable in anatomically difficult cases, such as

2

1234567890 ‘’“”

ICMCE IOP Publishing

IOP Conf. Series: Journal of Physics: Conf. Series 1016 (2018) 012006 doi :10.1088/1742-6596/1016/1/012006

scoliosis correction surgeries, with a reported 6-fold reduction in perforation rates and mean insertion

angle errors compared with conventional methods[4]. In the meta-comparison of navigation-assisted

versus conventional screw placement covering 28 clinical, 14 cadaveric, and 1 model-based study,

Tian [5], reported a higher overall accuracy of screw position in navigation-assisted procedures.

The Rosa spine robot[6], which has been used clinically, combines robots and navigation systems

to obtain the pose of surgical instruments and patients through two IR cameras. Under the assistance

of intra-operative images, the surgical robot is guided to the surgical position and finally assists

surgeons place pedicle screws. The navigation system of Rosa spine robot is through the optical

imaging system to achieve spatial positioning and such systems are vulnerable to the effect of intra-

operative objects' shelter, the surrounding light and metallic objects mirror reflection. What' s more,

the Renaissance guidance system[7], uses operating forceps or Hover-T to fix a miniature parallel

robot on the patient's spine. The C-arm takes anterior–posterior and lateral intra-operative fluoroscopic

images of the patient and transfers them to the workstation system for automatic image registration.

But the specially designed jig with three marker holes need to be fixed to the patient's body, causing

additional trauma to the patient.

In order to solve the above problems, this paper proposes a robotic navigation system based on O-

arm. One of the major problems of this system is to registration of patient space and intra-operation

image space. This study mainly introduces the registration method of the system.

2. Material and method

2.1. Material

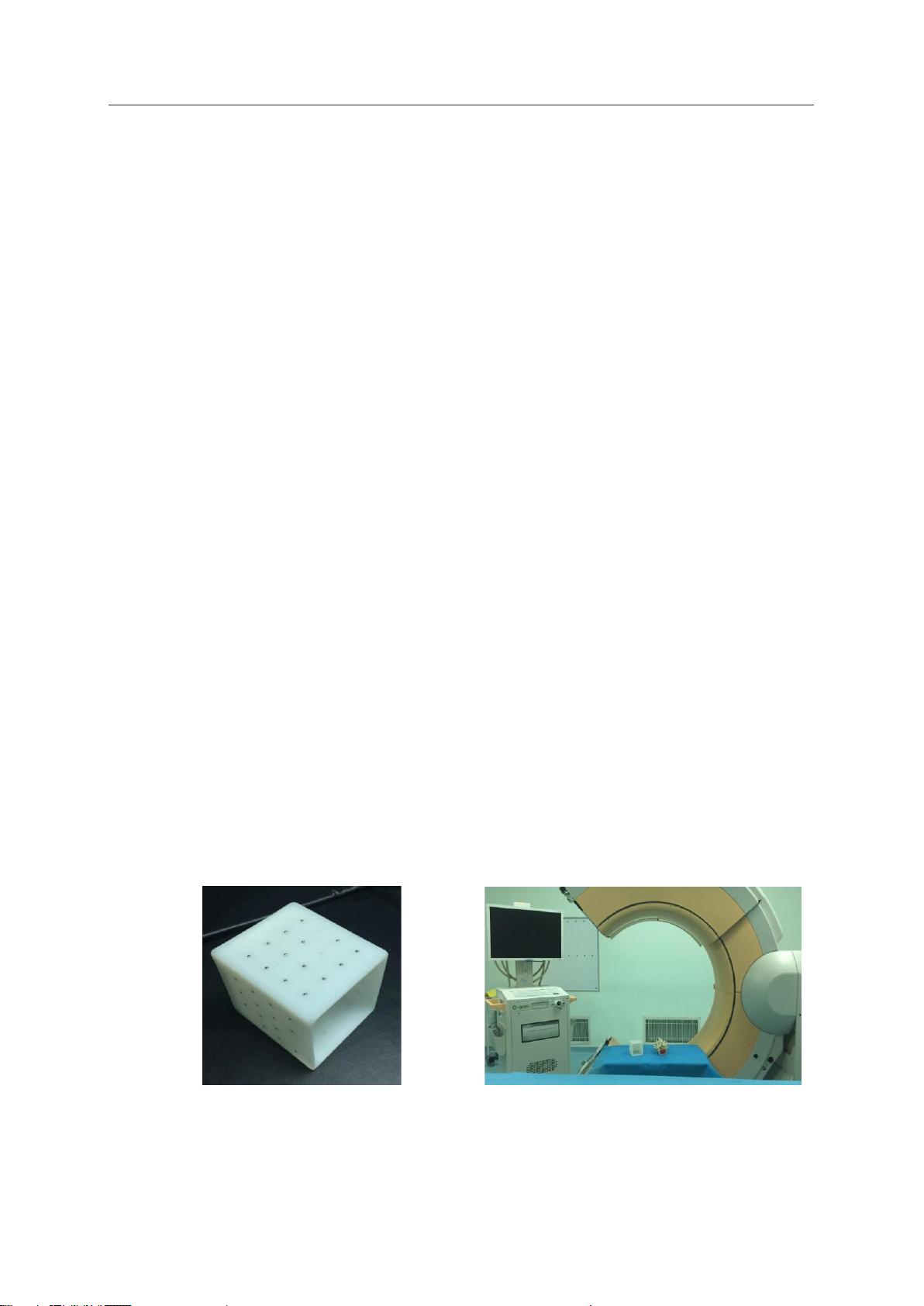

This study designed a calibration phantom to assist spatial registration and error calculations. Taking

the registration into account, the main criterion given for the phantom was the need to provide

multiple surfaces for placement the calibration sphere[8]. The solution for this criterion was to design

a 70mm × 70mm × 80mm cube calibration phantom. The four faces of which are accurately placed

with calibration holes, each with 16 calibration holes on each plane to provide sufficient test volume.

Figure 1 illustrates the used calibration phantom. The calibration holes were machined 15mm apart,

and the position error for the distance horizontally and vertically was within ± 0.02 mm. The diameter

and depth of the calibration hole is 2.5 mm, which ensures that the calibration sphere is exactly filled

in the hole.

The use of O-arm has been increasing in recent years, because the medical staff can leave the

operating theatre to decrease their exposure to radiation, during an O-arm 3D image acquisition[9].

The O-arm is a mobile intra-operative computed tomography imaging system optimized for bony

structures in spinal and orthopedic surgery [10]. Pixel size is 0.424 × 0.424 mm within a slice

thickness of 0.625 mm. Figure 2 illustrates the calibration phantom and the spinal phantom with the O-

arm.

Figure 1. The present calibration phantom. Figure 2. The two phantom with O-arm.

剩余6页未读,继续阅读

资源评论

weixin_38579899

- 粉丝: 2

- 资源: 979

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- 西门子S7-300博途植物萃取饮料生产线控制系统程序案例,编程软件采用博途STEP7加博途WINCC RT Pro 内有CAD工艺流程图和PDF版电气图供参考 博图版本V15.1及以上

- 西门子S7-1200博图程序案例,具体为一个3轴伺服螺丝机程序,画面采用西门子KTP700组态,程序语言采用SCL,程序结构清晰,写法十分经典,参考价值高 ,打开版本TIA V14及以上

- 西门子PLC1200伺服库卡机器人12工位博图程序例程,组态采用昆仑通态触摸屏,详细中文注释,PDF电路图参考,设备操作说明,物料BOM ,PLC和一台库卡机器人profinet通讯 PTO模式控制

- 西门子PLC-PVC送料配料系统控制程序画面实例,结构采用S7-314C+Wincc 程序内容包括1.配料系统物料分配 2.模拟量转,监测压力,称重程序, 3.PROFI

- 合资品牌汽车尾翼组装线(sw16可编辑+工程图+bom)全套技术资料100%好用.zip

- 147-西门子S7-1200博图程序案例, PID 恒温恒压供冷却水程序.触摸屏画面TP1200组态 霍尼韦尔电动比例阀PID控制水温,与两台西门子v20变频器模拟量PID控制水压 包括程序和Ep

- No.943 基于S7-300 PLC和Wincc Flexible触摸屏温室大棚控制 带解释的梯形图程序,接线图原理图图纸,io分配,组态画面

- FX5U程序框架模板(10轴) 程序由老工程师费尽心力的整理,把控制允许整理成简单的模板架构程序 程序讲解 1 轴的参数初始化 2 自动启动条件 3 安全条件(台湾称许可条件,这个可以避免运动打架

- 2022最新款程序,切条机切带机选用中达优控定长送料触摸屏一体机程序 三菱work2编辑软件,能用于超声切带和热切 配有触摸屏软件 送料方式可以自由选择,根据实际切长的用夹手加滚筒送料,切短的用滚

- 三相三电平PWM整流器闭环控制策略,采用三电平SVPWM算法

- 二极管箝位型三电平逆变器,NPC三电平逆变器 主要难点:三电平空间矢量调制(SVPWM),中点电位平衡调制等 MATLAB Simulink仿真模型,可提供参考文献

- 基于PLC的三部十层群控电梯,采用博途编写,提供程序,画面,接线图,设计报告,以及PPT,详情见图 需要的话,点击“加好友”和我加好友吧比心

- BootLoader IAP 上位机使用C#语言编程,下位机以STM32 系列为例,方便移植到其他厂家的MCU芯片,采用YModem协议传输文件 实现完成一键下载,含有上位机源码及MCU源码 企业

- 基于plc的污水处理厂控制系统,全部采用博途仿真完成,提供程序,画面,接线图.流程图,报告,PPT等相关文档 最终运行效果,详见上方演示视频

- fx5u 完整项目案例 包含触摸屏 ,6路脉冲控制 程序简单 适合新手学习

- Mitsubishi 三菱电机马达PMSM电机负载观测转矩前馈simulink 基于Luenberger降阶状态观测器,包含PMSM数学模型,PMSM双闭环PI矢量控制,并添加了前馈控制,采用SVP

资源上传下载、课程学习等过程中有任何疑问或建议,欢迎提出宝贵意见哦~我们会及时处理!

点击此处反馈

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功