Texas Instruments 16 AAJ 3Q 2015

IndustrialAnalog Applications Journal

Ceramic or electrolytic output capacitors

in DC/DC converters—Why not both?

Introduction

Switching power supplies are used in almost every end-

equipment that needs a long battery life, low heat genera-

tion, or to meet ENERGY STAR

®

guidelines. When

designing a switching power supply, it is difficult to decide

which output capacitor type to use.

Electrolytic capacitors have high equivalent series resis-

tance (ESR), making power loss high and transient

response too poor for use with tough load-response

requirements. However, electrolytic capacitors have stable

capacitance with high bias voltage and are inexpensive.

Ceramic capacitors have very low ESR, but capacitance

is reduced greatly with high bias voltage and can be

expensive for large values. The effective capacitance of a

ceramic capacitor can be less than half the rated capaci-

tance in many buck converters.

Today’s buck regulators typically use just one type of

output capacitor because it becomes too difficult to design

with different capacitances and ESRs. This forces many

designers to use more expensive capacitor types like

polymer or tantalum that provide lower ESR than electro-

lytic, but not as low as ceramic. Now a stable design with

mixed output capacitors can be prepared in minutes by

using new design tools. To illustrate this concept, this

article describes the design of a DC/DC supply with mixed

output capacitors.

Causes of output variation under load

The first step is to understand what the output capacitor

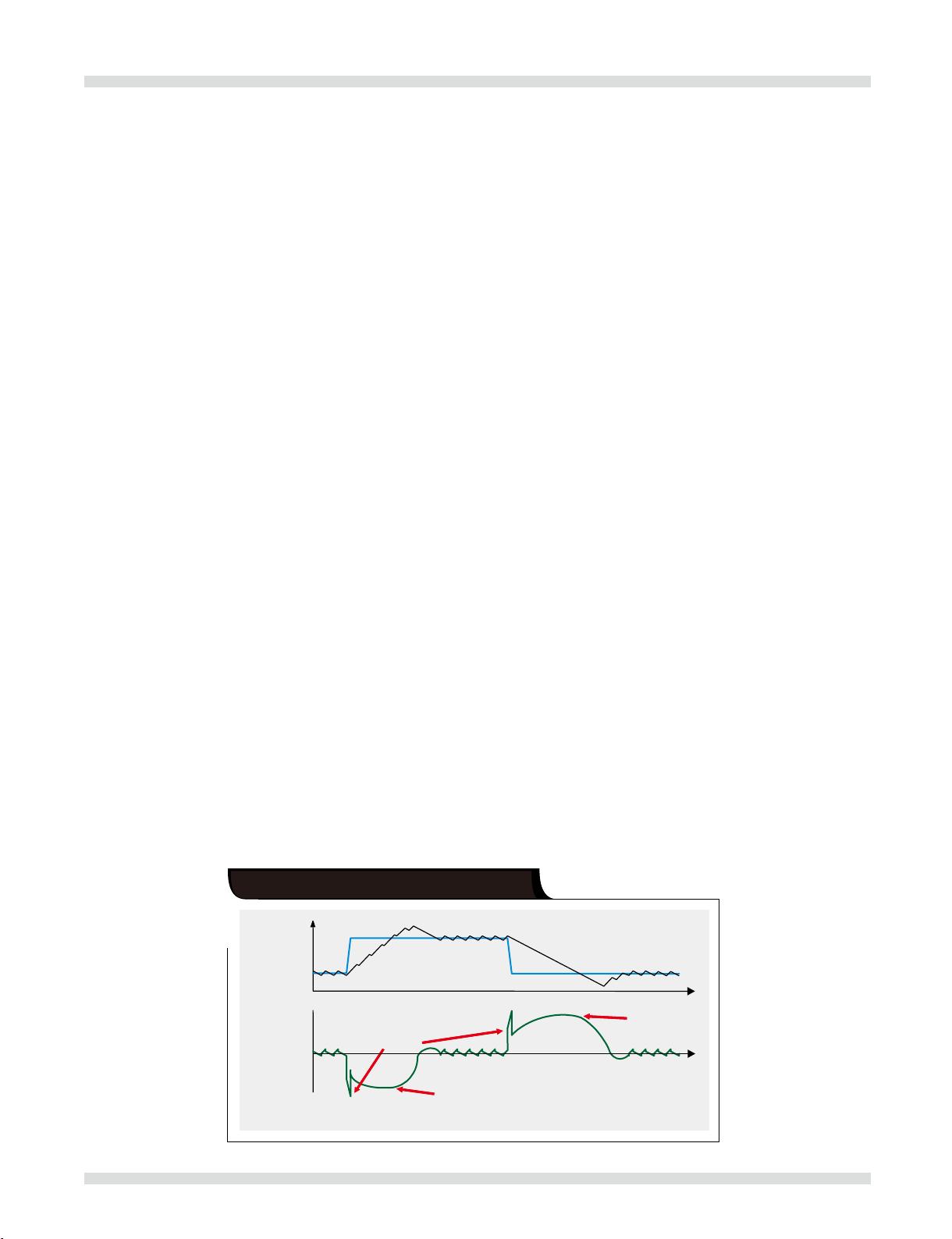

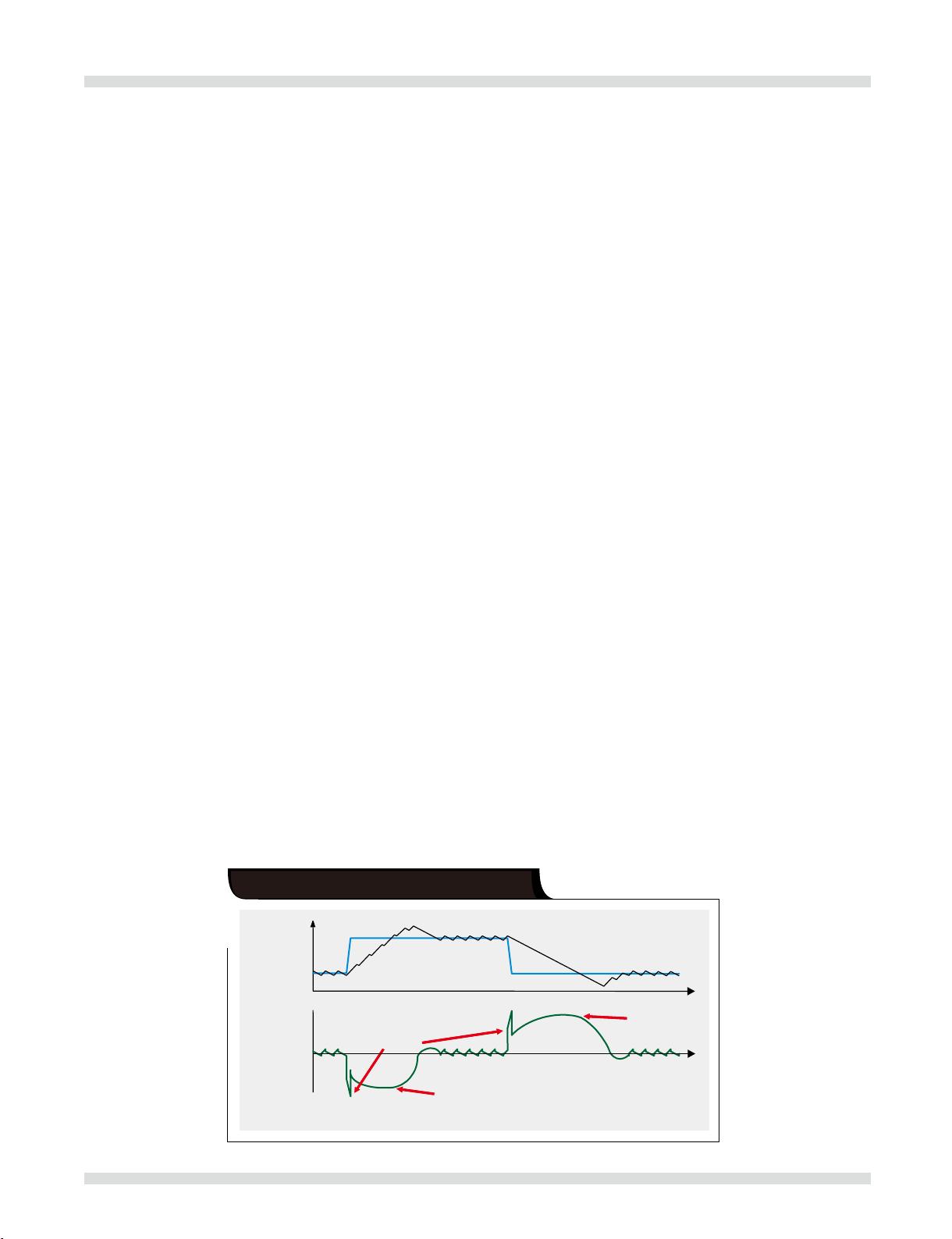

does in the system. Figure 1 shows idealized waveforms

with contributions of output-capacitor characteristics and

where they occur in a load-transient event.

The spikes at the load transients are primarily caused by

equivalent series inductance (ESL) or impedance of the

output cap at very high frequencies. Fixed inductor-

current slopes cause the bulk of the transient-event

disturbance in the inductor current to overshoot and

undershoot.

[1]

Recovery from the load-step transient also

causes overshoot and undershoot. Minimizing these lower

frequency errors relies on energy stored in the output

capacitor and the voltage-loop response time. So, it is

important to have a wide loop bandwidth, low ESR, and

enough output capacitance for adequate storage.

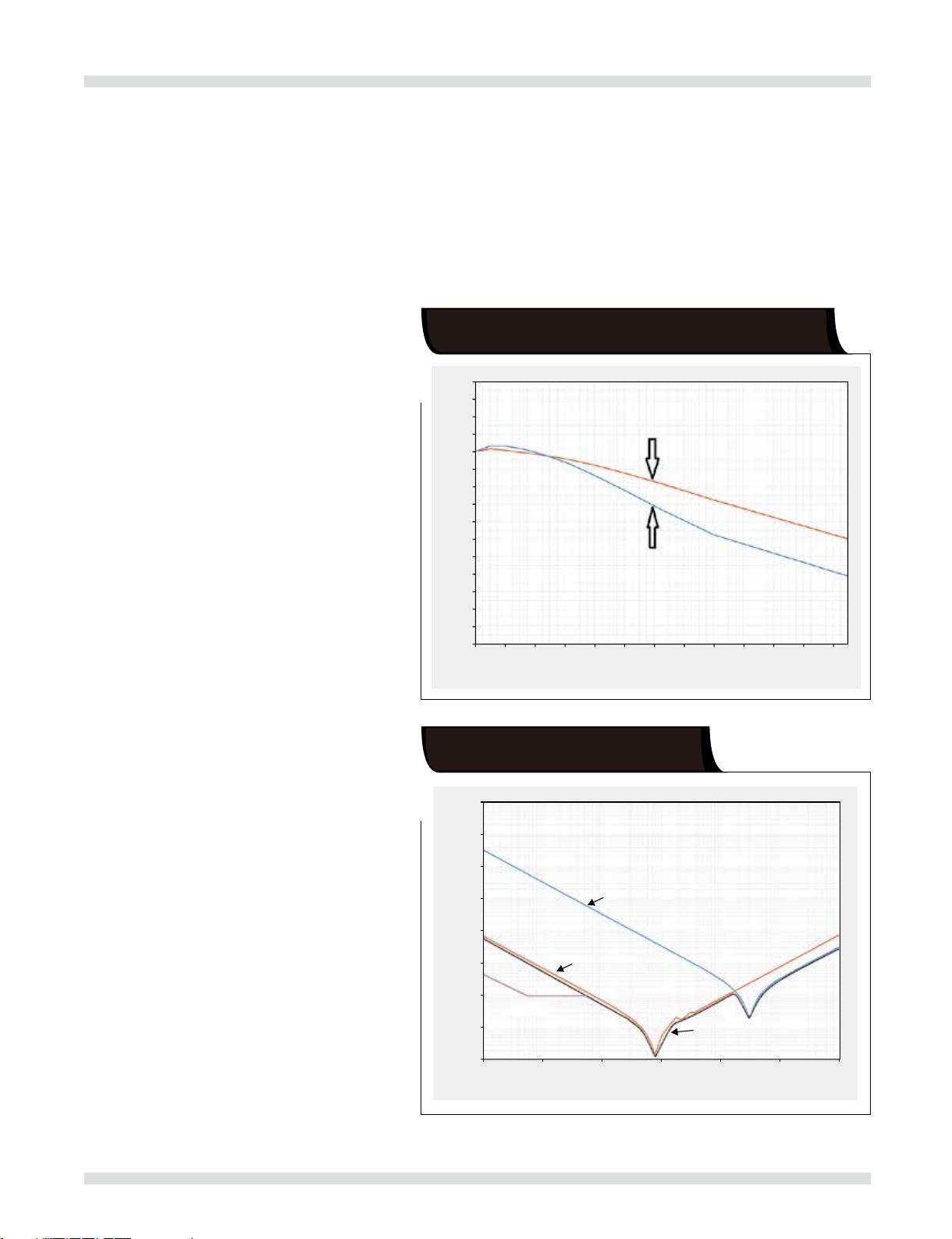

There are two primary factors for maintaining low-noise

output under load: 1) how much overshoot and under-

shoot the regulator will have; and 2) how much ripple

voltage occurs at the switching frequency. Peak overshoot/

undershoot is approximately the load-step current times

the impedance of output capacitors at the loop crossover

frequency (Equation 1). The equation emphasizes the

importance of having low output-capacitor impedance at

the loop crossover frequency (f

C

) to get low overshoot or

undershoot. The loop crossover frequency is usually

targeted to be one-tenth the switching frequency. A higher

loop crossover frequency minimizes overshoot/undershoot.

V

OVER/UNDER SHOOT

≈ D I

OUT

× Z

OUT

(f

C

) (1)

An approximation for output ripple voltage is the output

capacitor’s impedance at the switching frequency times

the peak-to-peak inductor current.

[2]

V

RIPPLE

≈ I

L(P-P)

× Z

OUT

(f

SW

) (2)

Equation 2 shows that the output ripple voltage can be

reduced by reducing the peak-to-peak inductor current,

which is controlled by increasing the inductance value.

By Michael Score

Senior Member Technical Staff, Field Applications Engineering

Figure 1. An idealized load-transient plot

Output

Currents

V

OUT

(AC

Coupled)

I

Load

0

ESR & ESL

ESR & ESL

C

Out

C

Out

I

Inductor

C

Out

& ESR

V

Spike

V

Under

V

Over

引言

在几乎所有需要长电池寿命

、

低发热量及满足能源之星

(ENERGY STAR

®

)

指导方针的终端设备中

,

都采用了开

关电源

。

当设计开关电源时

,

决定使用哪种类型的输出

电容器是一件很困难的事情

。

电解电容器具有高等效串联电阻

(ESR)

,

这使得功率损

耗很高且瞬态响应过差

,

因而无法在负载响应要求严苛

的场合中使用

。

然而

,

电解电容器在高偏置电压条件下

拥有稳定的电容

,

而且价格便宜

。

陶瓷电容器具有非常低的

ESR

,

但其电容在高偏置电压

下大幅减小

,

而且大数值陶瓷电容器的价格会很昂贵

。

在许多降压型转换器中

,

陶瓷电容器的有效电容有可能

不到其额定电容的一半

。

如今的降压型转换器通常只采用一种类型的输出电容

器

,

因为针对不同的电容和

ESR

进行设计将变得过于困

难

。

这造成许多设计人员被迫采用诸如聚合物或钽等更

加昂贵的电容器类型

,

此类电容器可提供低于电解电容

器的

ESR

,

但没有陶瓷电容器那么低

。

现在

,

通过运用

新型设计工具

,

只需短短几分钟便可做好使用混合型输

出电容器来实现稳定设计的准备

。

为了阐明该原理

,

本

文将描述采用混合型输出电容器进行的

DC/DC

电源设

计

。

在负载条件下发生输出变化的原因

第一步需要弄清输出电容器在系统所起的作用

。

图

1

给

在

DC/DC

转换器中采用陶瓷或电解输出

电容器

-

为什么不能兼用呢?

作者:

Michael Score

高级技术组成员,现场应用工程

图

1

:理想化的负载瞬变曲线图

AAJ 2015

年第三季度

德州仪器

模拟应用期刊

工业

出了理想化波形

,

并示出了输出电容器特性产生的影响

以及它们在负载瞬变过程中出现的位置

。

负载瞬变时出现的尖峰主要是由输出电容器的等效串联

电阻

(ESR)

或阻抗在非常高的频率下引起的

。

固定的电

感器电流斜坡导致电感器中的大部分瞬变扰动产生过冲

和下冲

。

[1]

另外

,

从负载阶跃瞬变的恢复过程也会引发

过冲和下冲

。

要想最大限度地减少这些低频误差

,

则需

仰仗输出电容器中存储的电能和电压环路响应时间

。

因

此

,

应拥有宽环路带宽

、

低

ESR

以及足够的输出电容

(

以提供充足的电能存储

),

这一点很重要

。

在负载条件下保持低噪声输出涉及两个主要的因素

:

1)

稳压器将具有多大的过冲和下冲

;

2)

在开关频率下出现

的纹波电压有多大

。

峰值过冲

/

下冲约为负载阶跃电流乘

以输出电容器在环路交叉频率下的阻抗

(

(1)

式

)。

该式

强调了在环路交叉频率

(f

C

)

下拥有低输出电容器阻抗对

于实现低过冲或下冲的重要性

。

环路交叉频率通常被定

为开关频率的十分之一

。

较高的环路交叉频率可最大限

度地抑制过冲

/

下冲

。

V

OVER/UNDER SHOOT

≈

Δ

I

OUT

x Z

OUT

(f

C

) (1)

输出纹波电压的一种近似计算法为

:

输出电容器在开关

频率下的阻抗乘以峰至峰电感器电流

。

[2]

V

RIPPLE

≈

I

L(P-P)

x Z

OUT

(f

SW

) (2)

(2)

式表明

:

输出纹波电压可通过减小峰至峰电感器电流

(

其通过增加电感值来控制

)

得以降低

。

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功