1880 IEEE JOURNAL OF SOLID-STATE CIRCUITS, VOL. 40, NO. 9, SEPTEMBER 2005

A 700

+

-mW Class D Design With Direct Battery

Hookup in a 90-nm Process

Brett Forejt, Senior Member, IEEE, Vijay Rentala, Jose Duilio Arteaga, and Gangadhar Burra

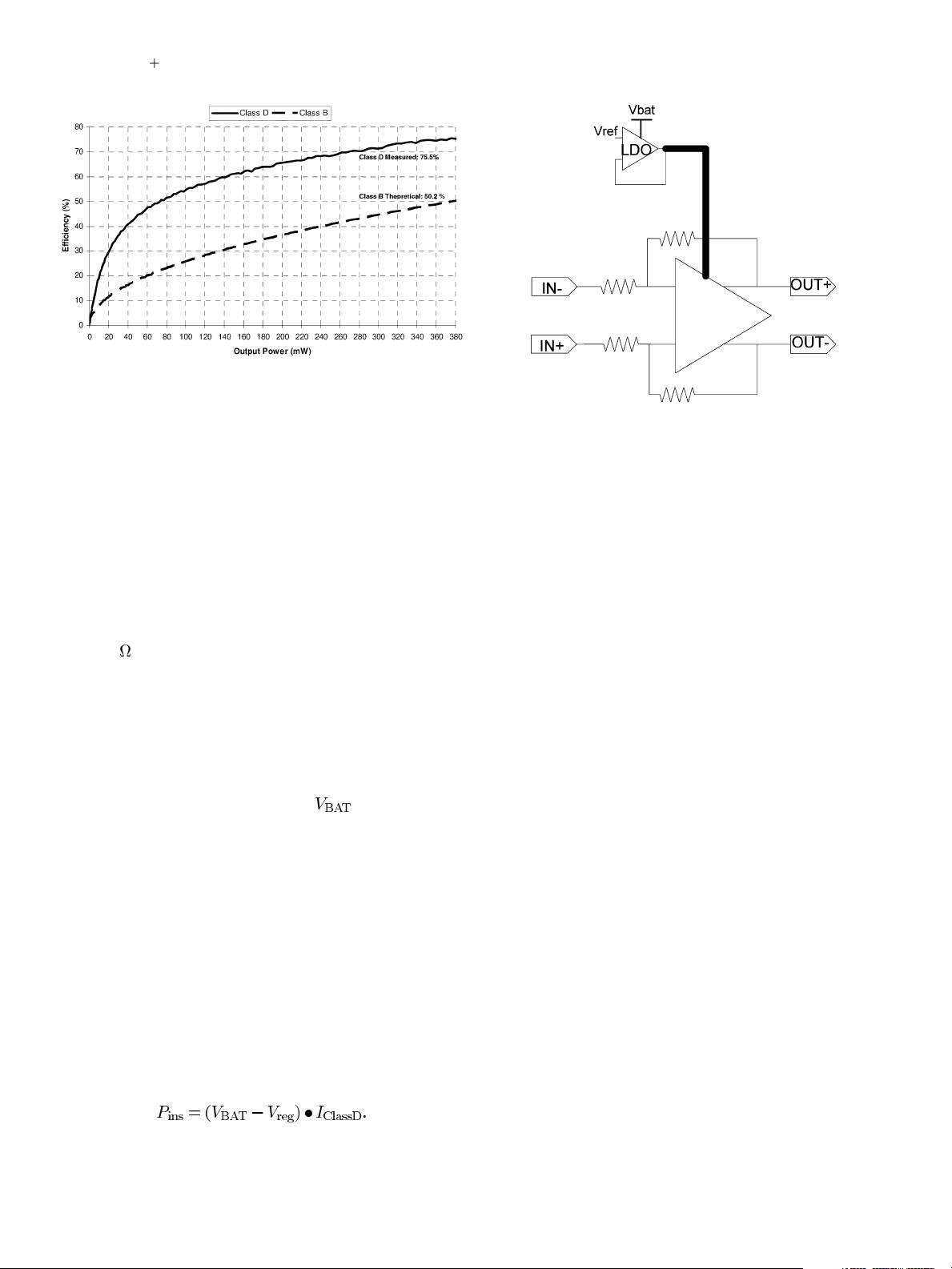

Abstract—A “battery connect” compatible class D (switching)

amplifier which is fully integrated in a 90-nm digital CMOS

process is presented. The integration of the amplifier requires no

additional masks, processing, or cost. This paper includes a brief

description of the circuit techniques that enable direct battery

(2.7–5.4 V) connection and allow support

6 7V

P2P

(700 mW

into 8

) output swing from a 4.2-V supply using devices that

operate solely with low gate voltages. The achieved SNR over

an audio (20 Hz to 20 kHz) bandwidth

98 5

dB and the total

harmonic distortion (THD) is better than 0.03% at 500 mW.

Efficiency is greater than 75% above 375 mW. The power supply

rejection ratio, which is a crucial parameter in modules connected

directly to the battery, is measured at 70 dB at 217 Hz. The area of

the switching amplifier is

0 44

mm

2

, where the power devices

occupy approximately 20% of the total.

Index Terms—Class D amplifier, common mode rejection ratio

(CMRR), efficiency, electromagnetic interference (EMI), low

drop-out regulator (LDO), power supply rejection ratio (PSRR),

pulse-width modulation (PWM), signal-to-noise ratio (SNR),

system-on-chip (SOC), total harmonic distortion (THD), ultra-

deep submicron (UDSM).

I. INTRODUCTION

C

LASS D amplifiers, due to their high efficiencies, are ex-

tremely attractive for systems-on-chip (SOCs) for mobile

and low-power applications, where battery life and reduced heat

are crucial parameters. Obtaining these efficiencies mandates

that the switching amplifiers are directly connected to the bat-

tery instead of a linear or a switching regulator output. Typical

handset battery voltages range from 2.7 to 5.4 V.

Continuous-time output amplifiers have a theoretical effi-

ciency of 78.5% and applied efficiencies near 30% while Class

D can approach 100% in theory and has practical efficiencies

of 70% or greater. More efficient power usage reduces wasted

battery energy which in turn increases battery life and reduces

the amount of heat generated by the device. Battery life and

reduced heat are important factors in the feasibility of SOC

designs.

Typical battery voltages in mobile technologies range from

as low as 2.7 V to as high as 4.8 V. During charging conditions,

the battery terminals may be as high as 5.4 V DC. These voltage

levels present a problem in ultradeep submicron (UDSM) pro-

cesses due to the fact that the maximum voltage rating of the

gate oxide is typically less than 1.5 V. In order to produce a

transistor that is reliable under these gate voltage stresses, extra

Manuscript received December 13, 2004; revised March 8, 2005. This work

was supported by Texas Instruments Incorporated.

The authors are with Texas Instruments, Inc., Dallas, TX 75243 USA (e-mail:

bforejt@ti.com; rvijay@ti.com; jarteaga@ti.com; gburra@ti.com).

Digital Object Identifier 10.1109/JSSC.2005.848147

processing is normally required for each wafer. This extra pro-

cessing decreases the profitability of the design.

Using a standard 90-nm digital process with no mask or pro-

cessing adders, we have achieved

700-mW output Class D am-

plifier with direct battery hookup. The SNR is

98.5 dB and the

THD is better than 0.03% at full power. The PSRR of the system

is measured at

70 dB at 217 Hz. The area is mm .

II. P

RIOR

ART

There are two main approaches to the design of class D am-

plifiers: open loop and closed loop. The open-loop approach

directly feeds signal into the PWM generator. The output of

the PWM generator drives the output stage [8]. The open-loop

approach offers reasonable performance but suffers from poor

supply and substrate noise rejection. Due to the noise present

on the battery because of various other blocks in an SOC, the

power supply rejection and substrate noise rejection degrade the

quality of the audio signal at the output.

The closed-loop systems use negative feedback to improve

the performance of the Class D amplifier. Feedback systems in-

herently offer higher supply and substrate noise rejection. The

amount of rejection can be improved by increasing the order of

the loop filter [7].

Class D amplifiers with binary PWM modulation require ex-

ternal filters to reconstruct the signal and reduce electromag-

netic interference (EMI). There are techniques that may relax

the output filter requirement by using digital signal processing

techniques [1]. Double-sided natural sampling PWM modula-

tion or ternary PWM modulation relaxes the requirements for

the external filtering [5].

The other major issue in the design of class D in a deep sub-

micron process is the device limitations. There are few known

techniques to overcome these device limitations like the use of

level shifters [8].

Presented herein is a simple first-order closed-loop architec-

ture with ternary modulation that does not require any external

filter and directly hooks up to a battery in a process that does not

allow voltages more than 1.5 V across gate and source terminals.

III. D

ESIGN CHALLENGES

Low-efficiency designs dissipate power locally on chip, thus

generating an unacceptable amount of heat. For Example, if 1 W

is delivered to the load from a 50% efficient design, 1 W must

be dissipated inside the package for just this one function! The

adverse affects of heat in integrated circuits are well known [9],

and at its limit the temperature increase can cause damage to the

device [10].

0018-9200/$20.00 © 2005 IEEE

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功