2

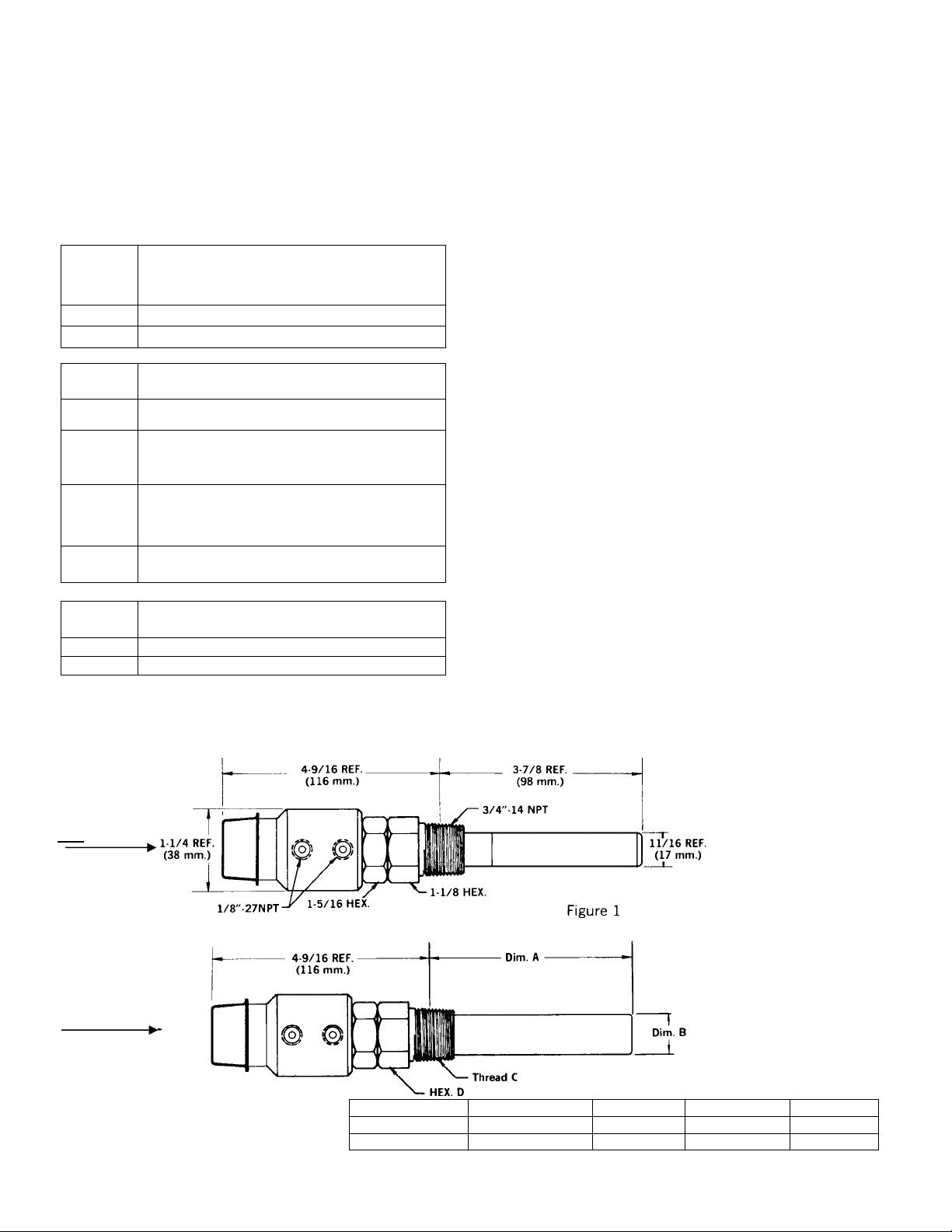

Thermowell Dim. A Dim B. Thread C Hex. D

85031-A1 4 - 3/16 (106mm) 7/8 (22mm) 3/4-14 N PT 1-1/8

85031-A2 4 - 31/64 (114mm) 1.10 (28mm) 1 - 11 -1/2NPT 1-3/8

3rd &

4th

DIGIT

BODY MATERIAL

01 Aluminum

19 Stainless Steel

2nd

DIGIT

INSTALLATION ACCESSORIES

0

Stainless St. bushing with 3/4" - 14 NPT thread

1

Stainless Steel thermowell and Beryllium

Copper sleeve with 3/4" - 14 NPT thread.

Rating: 5,000 psi max. @ 400° F.

2

High Pressure Stainless Steel Thermowell and

Beryllium Copper sleeve with 1" – 11-1/2 NPT

thread. Rating: 10,000 psi Max. @ 400° F.

3

Replacement temperature sensor without

installation accessories

SUFFIX

LETTER

TYPE OF ACTION

A

Direct Acting - Vents on increase

B

Reverse Acting - Closes vent on increase

Reset Differential: 6 to 16° F. (3.3 to 9° C.) non-adjustable

Repeatability:............................................... ±5° F. (2.8° C.)

Mounting Dimensions: .................................... See Figure 1

Approximate Shipping Weight:

Without Thermowell .............................. 1-1/4 lbs. (.6 Kg)

With 85031-A1 Thermowell Kit.............. 1-1/2 lbs. (.7 Kg)

With 85031-A2 Thermowell Kit.............. 2-1/8 lbs. (1 Kg)

Models Available:

85026-X0XXX

INSTALLATION

NOTE: Handle instrument with care to avoid damage to

sensing element.

Bulb Location - Correct location is the most important

detail of sensor installation. The bulb should be installed at

a point of true representative temperature in good

circulation with maximum insertion depth. If a

thermometer is used, its sensing element should be

installed adjacent to the bulb.

Mounting: The 85026-Series temperature sensor may be

mounted in any position, but vertical (upright) is

recommended. Vent openings should have fittings installed

turned down. Care should be taken to prevent foreign

matter from entering the valve ports during installation.

If the sensor is out of doors or in any way exposed to

water during cleaning, etc., it should be mounted in a

position which will prevent water entry into the valve

housing. Water trapped in the housing will impair

operation and could freeze during winter months. The 1/8"

- 27 NPT connections can be used for piped vent operation

if gas is used as the operating medium.

Unless ordered with a thermowell, each sensor model is

equipped with a bushing with 3/4" - 14 NPT external

threads. CAUTION: Do NOT use pipe wrench, channel

locks, etc., on valve body when tightening into bushing or

thermowell.

To mount sensor, loosen jam nut (see Fig. 5, detail 9)

and remove bushing. Install bushing in desired location.

Place sensor in bushing, positioning it with the desired port

orientation. Tighten jam nut.

Connections (See Figure 1): The sensor has two 1 / 8"

- 27 NPT connections used for control pressure (port "IN")

and piped vent operation (port "V"). Control pressure must

be provided through a .032" (.8 mm) diameter or smaller

orifice.

CAUTION: The piped vent from the sensor cannot be used

as a supply source for any other equipment. If sensor vent

is restricted in this manner, faulty operation will result.

NOTE: If St. St. thermowell is required, specify No. 85031-A1 or

A2 Thermowell Kit.

WITH

BUSHING

WITH

THERMOWELL

wyr_062012-10-17不错的文献,内容很详细,感谢LZ的分享!

wyr_062012-10-17不错的文献,内容很详细,感谢LZ的分享! 大鹏集成2014-02-28文献内容很详细,感谢LZ

大鹏集成2014-02-28文献内容很详细,感谢LZ 我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜 信息提交成功

信息提交成功