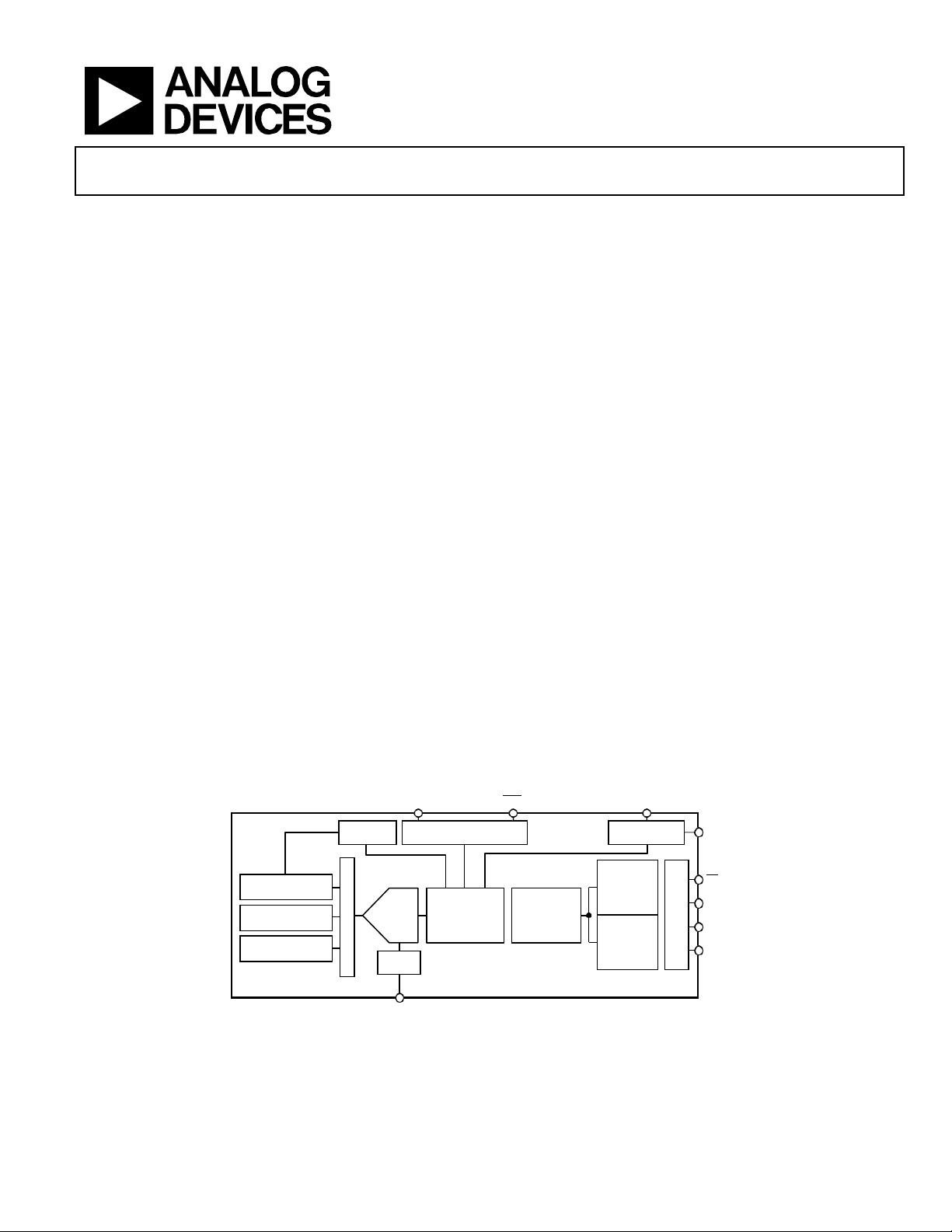

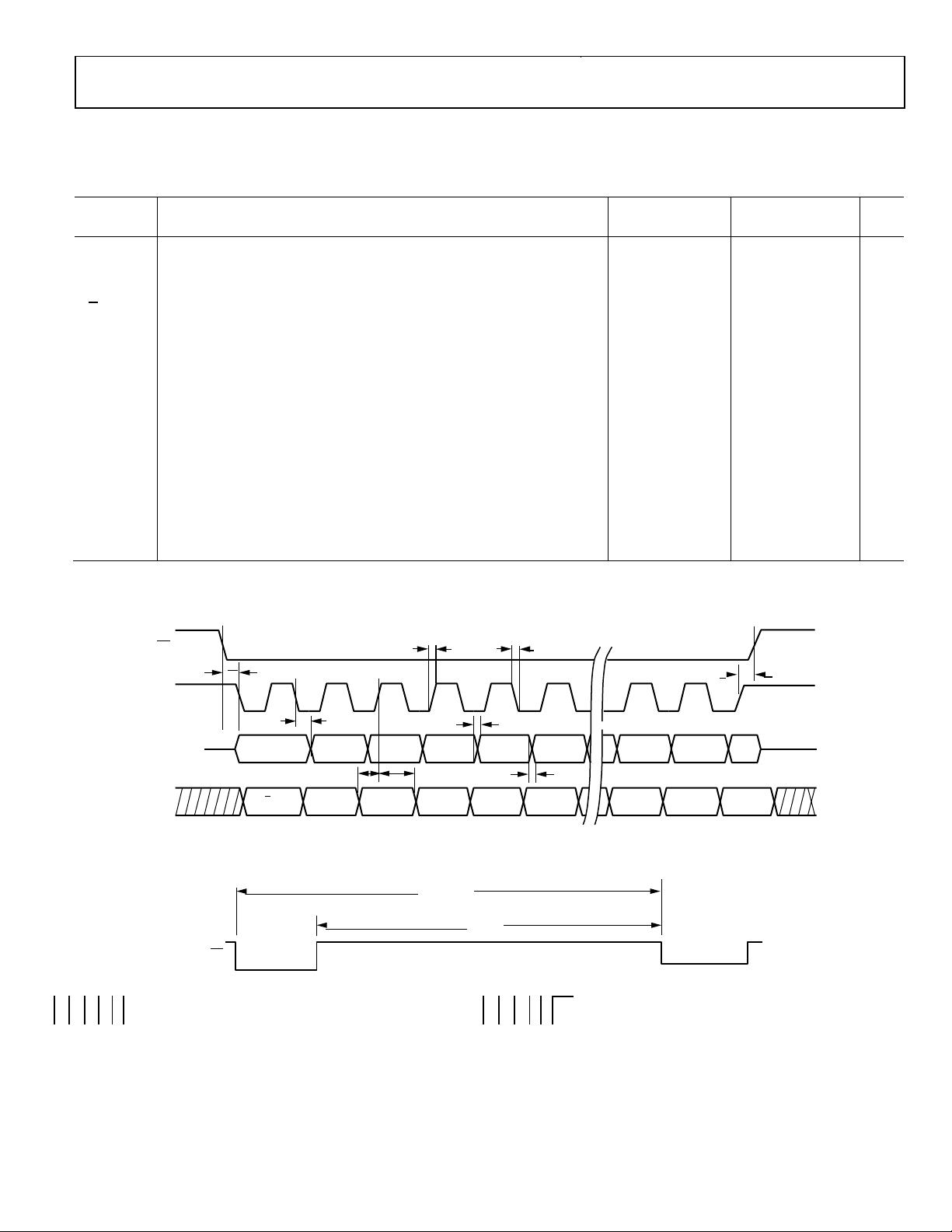

ADIS16467是一款精密的微电子机械系统(MEMS)惯性测量单元(IMU),具备三轴陀螺仪和三轴加速度计。该传感器在出厂前已经经过完整的动态性能优化,通过信号调理来达到最佳的性能表现。工厂校准会针对每个传感器的灵敏度、偏移、对准、线性加速度(陀螺仪偏移)和冲击点(加速度计位置)进行表征。因此,每个传感器都配备了能够适应广泛条件的动态补偿公式,保证了在各种情况下都能提供精确的传感器测量值。 ADIS16467为工业系统提供了一种简单且成本效益高的方法,用于集成准确的多轴惯性传感,相比离散设计的复杂性和所需投资而言尤为突出。所有必需的运动测试和校准都包含在生产过程中的工厂环节,极大减少了系统集成时间。紧密的正交对准简化了导航系统中的惯性框架对准。其串行外设接口(SPI)和寄存器结构为数据采集和配置控制提供了简单易用的接口。 ADIS16467传感器采用的是铝制模块封装,尺寸大约为22.4mm×24.3mm×9mm,并带有14脚连接器接口。产品数据表列出了它的一些主要特性,例如: - 三轴、数字陀螺仪,动态范围分为±125°/sec、±500°/sec、±2000°/sec三种型号。 - 其中ADIS16467-1型号具有2°/hr的在运行偏移稳定性,而ADIS16467-1和ADIS16467-2型号具有0.15°/√hr的角度随机游走。 - ±0.05°的轴间对准误差。 - 三轴、数字加速度计,动态范围为±40g,具有13μg的在运行偏移稳定性。 - 提供三轴、增量角度和增量速度输出。 - 工厂校准的灵敏度、偏移和轴向对准。 - 校准温度范围从−40°C到+85°C。 - 支持SPI兼容的数据通信。 - 可编程的操作与控制。 - 提供自动和手动偏移校正控制。 - 数据准备就绪指示器用于同步数据采集。 - 外部同步模式包括直接、脉冲、缩放和输出。 - 可按需进行惯性传感器和闪存的自我测试。 - 单电源操作(VDD): 3.0V至3.6V。 - 能承受2000g的机械冲击。 - 工作温度范围为−40°C至+105°C。 ADIS16467适用于多种应用领域,如导航和稳定系统,以及其他需要精确运动跟踪的场合。 由于文档是扫描识别而成,难免会有识别错误,以下是对文档部分识别错误的校正和通顺处理: 在“工厂校准的灵敏度、偏移和轴向对准”一句中,“轴向对准”可能是对原文“axial alignment”(轴向对准)的误识,应修正为“轴向对准”。 “提供三轴、增量角度和增量速度输出”一句中的“提供”可能是多余的,原文“Triaxial, delta angle, and delta velocity outputs”(三轴、增量角度和增量速度输出)应该直接翻译为“三轴、增量角度和增量速度输出”。 在“单电源操作(VDD): 3.0V至3.6V”一句中,“单电源操作(VDD)”应对应原文的“Single-supply operation (VDD)”(单电源操作),而“3.0V至3.6V”则是电压范围的描述,与原文完全一致。 这些信息和知识点说明了ADIS16467是一款设计用于满足工业应用需求的六轴传感器模块,其中包含高性能的陀螺仪和加速度计,并在出厂前进行了全面的校准和测试。由于其紧凑的尺寸、简单的接口和丰富的功能,ADIS16467可方便地集成到多种应用中,为系统设计者提供高精度的惯性测量解决方案。

剩余31页未读,继续阅读

- 粉丝: 0

- 资源: 3

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- springboot layui 装修验收管理系统(源码+sql)-springboot毕业项目,适合计算机毕-设、实训项目、大作业学习.zip

- 洞见研报中国现制茶饮行业洞察报告- 茶韵新篇:现制茶饮行业的繁荣与前景

- 同步磁阻电机SynRM无传感器高频注入HFI驱动matlab离散模型,使用方波注入,用于低速运行,仿真中使用的是50RPM 用于学习研究

- springboot+vue+redis前后端分离 爱家商城项目(源码+sql)-springboot毕业项目,适合计算机毕-设、实训项目、大作业学习.zip

- CH341SER-ANDROID.zip

- springboot高校跳蚤市场平台(源码+论文报告)-springboot毕业项目,适合计算机毕-设、实训项目、大作业学习.zip

- 【龙艺集团,洞见研报】面对降本增效的挑战,企业与员工如何找到人力管理的平衡点?(降本增效、制造业转型、人力降本)

- springboot美食生活分享平台(源码+论文报告)-springboot毕业项目,适合计算机毕-设、实训项目、大作业学习.zip

- 基于滑膜控制的主动前轮转向(AFS),以横摆角速度偏差为输入(也可以添加质心侧偏角) ,附加转角为输出 模型包括整车七自由度模型、AFS控制器 可以有效改善车辆稳定性

- springboot网上宠物用品商城系统(源码+sql+论文报告)-springboot毕业项目,适合计算机毕-设、实训项目、大作业学习.zip

- 洞见研报周报时讯11.18-11.22

- springboot社区团购管理系统的设计与实现_975sz--论文-springboot毕业项目,适合计算机毕-设、实训项目、大作业学习.zip

- 洞见研报周报时讯11.25-11.29

- hedrive-dir.7z

- springboot网上酒类商城系统(源码+论文报告)-springboot毕业项目,适合计算机毕-设、实训项目、大作业学习.zip

- 洞见研报周报时讯12.2-12.6

信息提交成功

信息提交成功