没有合适的资源?快使用搜索试试~ 我知道了~

资源推荐

资源详情

资源评论

DATASHEET

ButterflyGyro

™

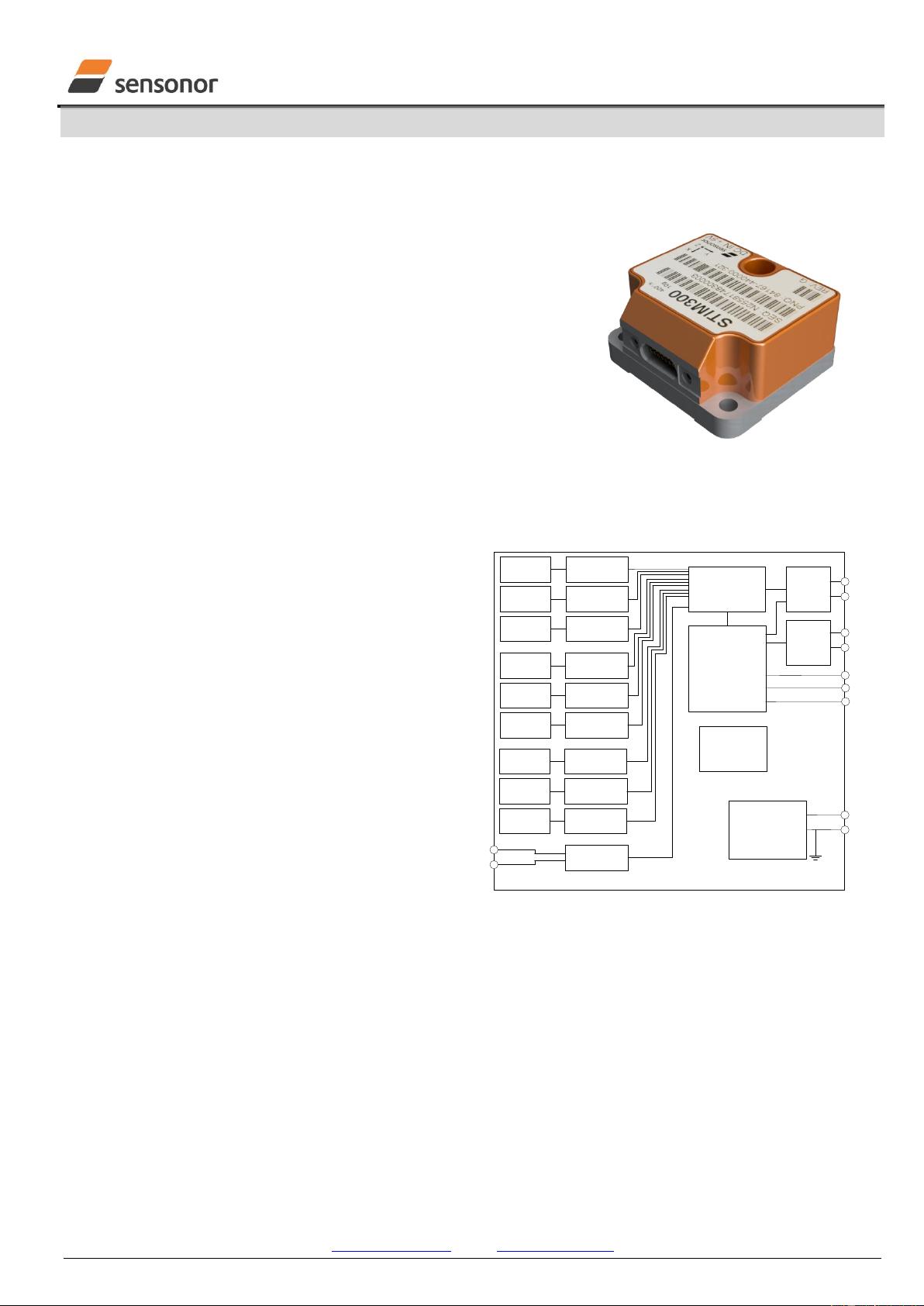

STIM300 Inertia Measurement Unit

TS1524 rev.24 1/85 June 2018

1 FEATURES

o Miniature package

o Low noise

o Low bias instability

o Excellent performance in vibration and shock environments

o 9 axes offered in same package

o Electronically calibrated axis alignment

o Gyros based on Sensonor ButterflyGyro

TM

o Single-crystal silicon technology

o No intrinsic wear-out effects

o High stability accelerometers and inclinometers

o Separate “AUX” input for 24 bit ADC

o Insensitive to magnetic fields

o Full EMI compliance

o Digital interface, RS422

o Fully configurable

o Continuous self-diagnostics

o RoHS compatible

2 GENERAL DESCRIPTION

STIM300 is an IMU consisting of 3 high accuracy

MEMS-based gyros, 3 high stability accelerometers

and 3 high stability inclinometers in a miniature

package. Each axis is factory-calibrated for bias,

sensitivity and compensated for temperature effects

to provide high-accuracy measurements in the

temperature range -40°C to +85°C. The unit runs off

a single +5V supply.

STIM300 communicates via a standard high-level

RS422 interface. The use of a 32-bit RISC ARM

microcontroller provides flexibility in the

configuration, like choice of output unit, sample rate,

low pass filter ‒3dB frequency and RS422 bit-rate

and protocol parameters. All configurable parameters

can be defined when ordering or set by customer.

When STIM300 is powered up, it will perform an

internal system check and synchronise the sensor

channels. As an acknowledgement of the complete

power-up sequence, it will provide special datagrams

containing part number, serial number and

configuration data. STIM300 will then automatically

proceed to provide measurement data. Connect power

and STIM300 will provide accurate measurements over the RS422 interface.

The measurement data is transmitted as packages of data on a fixed format (datagram) at intervals given by the

sample rate together with a synchronization signal (TOV). The datagram is in binary coded format in order to have an

efficient transfer of data. In addition to the measurement data itself, the datagram contains an identifier, status bytes

and a 32 bit CRC (Cyclic Redundancy Check) to provide high degree of fault detection in the transmissions. The

status bytes will flag any detected errors in the system. STIM300 can also be configured to transmit data only when

triggered by a separate digital input signal (ExtTrig).

For more advanced users, the gyro may be put in Service Mode. In this mode all the configuration parameters can be

intermediately or permanently changed by overwriting the current settings in the flash memory. In Service Mode the

commands and responses are in a human readable format (ASCII); to enable the use of terminal-type software during

typical product integration. Service Mode also provides the ability to perform single measurements, perform

diagnostics and obtain a higher detail level of detected errors reported in the status bytes.

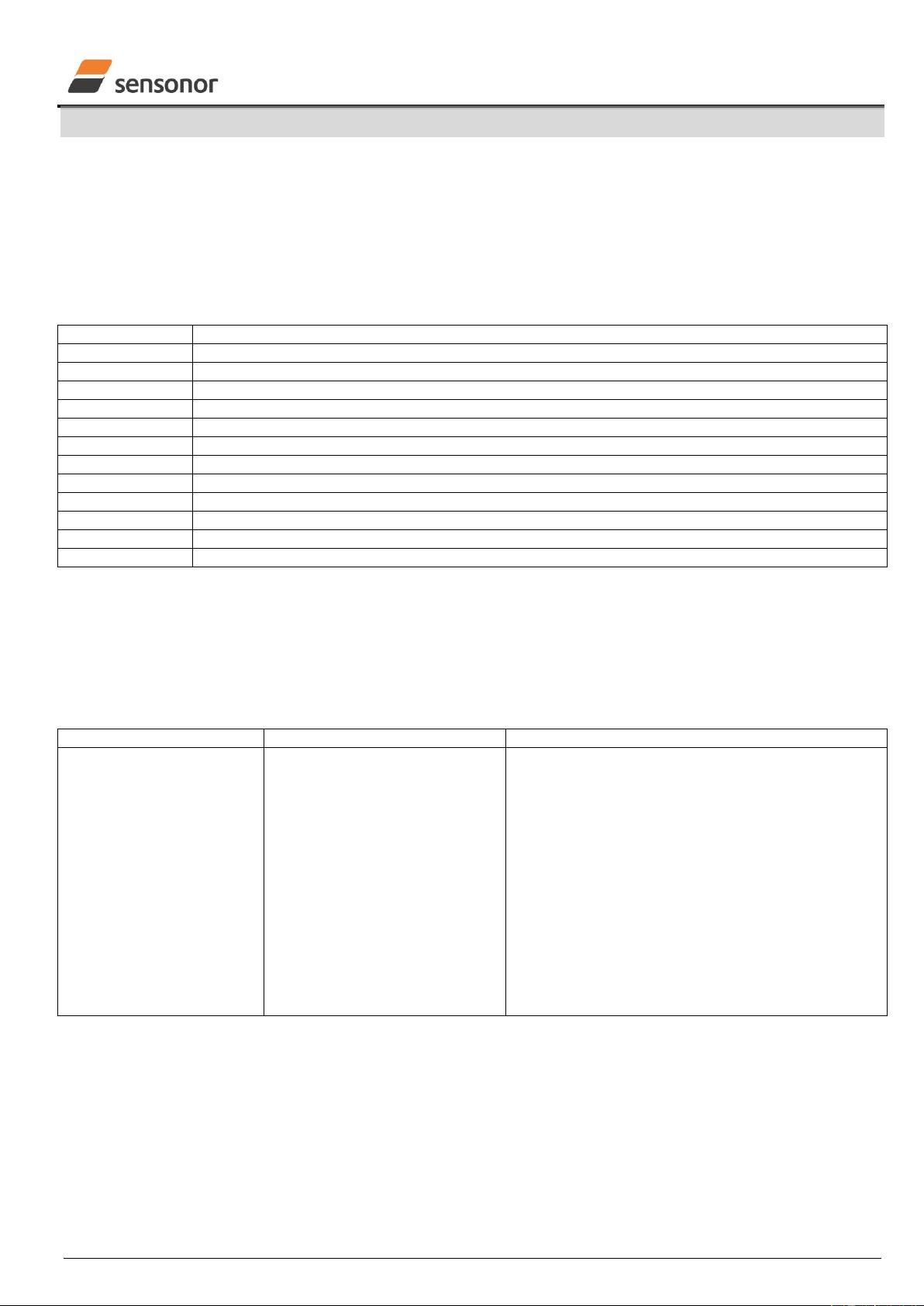

TxData+

TxData-

RxData+

RxData-

+5V

GND

POWER

MANAGEMENT /

VOLTAGE AND

FREQUENCY

REFERENCES

X-AXIS

GYRO

Y-AXIS

GYRO

Z-AXIS

GYRO

SELF-

DIAGNOSTICS

GYRO DRIVE

+ ADC + LPF

RS422

OUTPUT

DRIVER

RS422

INPUT

BUFFER

ExtTrig

SYSTEM

CONTROLLER

GYRO DRIVE

+ ADC + LPF

GYRO DRIVE

+ ADC + LPF

X-AXIS

ACC.

Y-AXIS

ACC.

Z-AXIS

ACC.

ADC + LPF

TOV

ADC + LPF

ADC + LPF

ADC + LPF

AUX+

AUX-

Reset

X-AXIS

INCL.

Y-AXIS

INCL.

Z-AXIS

INCL.

ADC + LPF

ADC + LPF

ADC + LPF

CALIBRATION

AND

COMPENSATION

Figure 2-1: STIM300 FUNCTION BLOCK DIAGRAM

Sensonor AS

Phone: +47 3303 5000 - Fax: +47 3303 5005

sales@sensonor.com www.sensonor.com

(38.6mm x 44.8mm x 21.5mm)

DATASHEET

ButterflyGyro

™

STIM300 Inertia Measurement Unit

TS1524 rev.24 2/85 June 2018

3 TABLE OF CONTENTS

DOCUMENT HISTORY ....................................................................................................................................................................... 1

1 FEATURES .................................................................................................................................................................................. 1

2 GENERAL DESCRIPTION .......................................................................................................................................................... 1

3 TABLE OF CONTENTS ............................................................................................................................................................... 2

4 DEFINITIONS AND ABBREVIATIONS USED IN DOCUMENT ................................................................................................... 3

4.1 Definitions ............................................................................................................................................................................ 3

4.2 Abbreviations ....................................................................................................................................................................... 3

5 ABSOLUTE MAXIMUM RATINGS ............................................................................................................................................... 3

6 SPECIFICATIONS ....................................................................................................................................................................... 4

6.1 TYPICAL PERFORMANCE CHARACTERISTICS ............................................................................................................ 11

6.1.1 GYRO CHARACTERISTICS ...................................................................................................................................... 11

6.1.2 ACCELEROMETER CHARACTERISTICS ................................................................................................................ 15

6.1.3 INCLINOMETER CHARACTERISTICS ..................................................................................................................... 18

6.1.4 AUX CHARACTERISTICS ......................................................................................................................................... 21

6.2 Configurable parameters ................................................................................................................................................... 23

6.3 Datagram specifications ..................................................................................................................................................... 24

6.3.1 Part Number datagram............................................................................................................................................... 24

6.3.2 Serial Number datagram ............................................................................................................................................ 25

6.3.3 Configuration datagram.............................................................................................................................................. 26

6.3.4 Extended Error Information datagram ........................................................................................................................ 29

6.3.5 Normal Mode datagram ............................................................................................................................................. 30

6.3.6 Cyclic Redundancy Check (CRC) .............................................................................................................................. 31

6.4 Status byte ......................................................................................................................................................................... 32

7 MECHANICAL ........................................................................................................................................................................... 33

7.1 Mechanical dimensions ...................................................................................................................................................... 33

7.2 Advice on mounting orientation .......................................................................................................................................... 34

7.3 Pin configuration ................................................................................................................................................................ 34

7.4 Definition of axes ............................................................................................................................................................... 34

8 BASIC OPERATION .................................................................................................................................................................. 35

8.1 Reset ................................................................................................................................................................................. 35

8.2 External Trigger ................................................................................................................................................................. 35

8.3 Time of Validity (TOV) ........................................................................................................................................................ 36

8.4 Auxiliary input..................................................................................................................................................................... 37

8.5 Operating modes ............................................................................................................................................................... 37

8.5.1 Init Mode .................................................................................................................................................................... 38

8.5.2 Normal Mode ............................................................................................................................................................. 38

8.5.3 Service Mode ............................................................................................................................................................. 46

8.6 Self-diagnostics .................................................................................................................................................................. 46

9 COMMANDS IN NORMAL MODE ............................................................................................................................................. 47

9.1 N (PART NUMBER DATAGRAM) command ..................................................................................................................... 47

9.2 I (SERIAL NUMBER DATAGRAM) command ................................................................................................................... 47

9.3 C (CONFIGURATION DATAGRAM) command ................................................................................................................. 48

9.4 E (EXTENDED ERROR INFORMATION DATAGRAM) command .................................................................................... 48

9.5 R (RESET) command ........................................................................................................................................................ 48

9.6 SERVICEMODE command ................................................................................................................................................ 48

10 COMMANDS IN SERVICE MODE ......................................................................................................................................... 50

10.1 i (INFORMATION) command ......................................................................................................................................... 51

10.2 a (SINGLE-SHOT MEASUREMENT) command ............................................................................................................ 56

10.3 c (DIAGNOSTIC) command ........................................................................................................................................... 58

10.4 d (DATAGRAM FORMAT) command ............................................................................................................................ 60

10.5 t (TRANSMISSION PARAMETERS) command ............................................................................................................. 62

10.5.1 User-defined bit-rate .................................................................................................................................................. 62

10.6 r (LINE TERMINATION) command ................................................................................................................................ 64

10.7 u (OUTPUT UNIT) command ......................................................................................................................................... 65

10.8 f (LP FILTER -3dB FREQUENCY) command ................................................................................................................ 66

10.9 m (SAMPLE RATE) command ....................................................................................................................................... 68

10.10 k (AUX COMP) command .............................................................................................................................................. 69

10.11 g (GYRO G-COMP) command ....................................................................................................................................... 70

10.12 s (SAVE) command ....................................................................................................................................................... 73

10.13 x (EXIT) command ......................................................................................................................................................... 74

10.14 z (RESTORE TO FACTORY SETTINGS) command ..................................................................................................... 76

10.15 ? (HELP) command ....................................................................................................................................................... 78

11 MARKING .............................................................................................................................................................................. 83

12 CONFIGURATION / ORDERING INFORMATION ................................................................................................................. 84

DATASHEET

ButterflyGyro

™

STIM300 Inertia Measurement Unit

TS1524 rev.24 3/85 June 2018

4 DEFINITIONS AND ABBREVIATIONS USED IN DOCUMENT

4.1 Definitions

g

0

= 9.80665m/s

2

(standard gravity)

4.2 Abbreviations

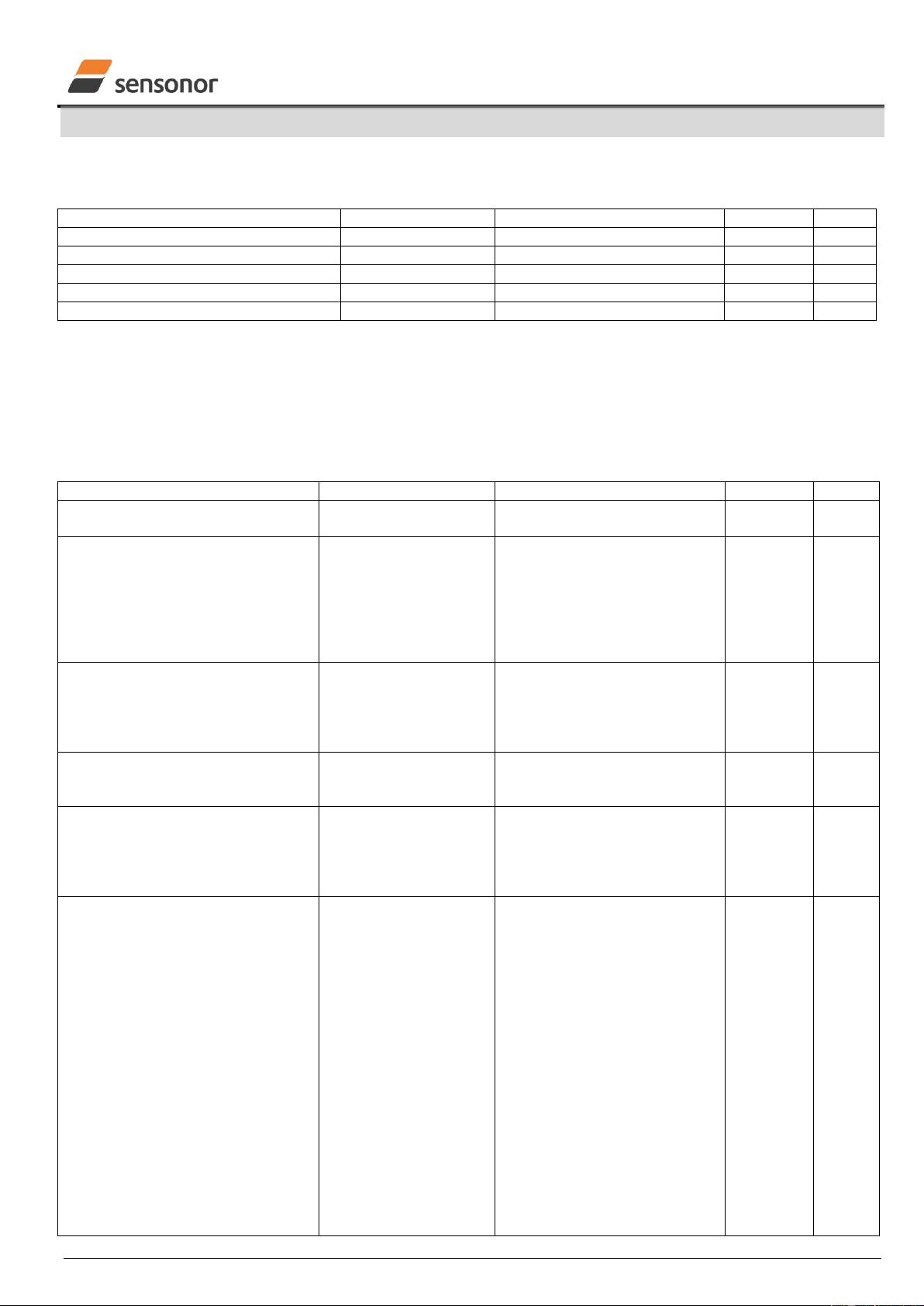

Table 4-1: Abbreviations

ABBREVIATION

FULL NAME

BCD

Binary Coded Decimal

BSL

Best Straight Line

CIC-filter

Cascaded Integrator-Comb filter

CR

Carriage Return

FS

Full-Scale

LF

Line Feed

LP filter

Low-Pass filter

tbd

to be defined

LSB

Least Significant Byte

MSB

Most Significant Byte

lsb

Least significant bit

TOV

Time of Validity

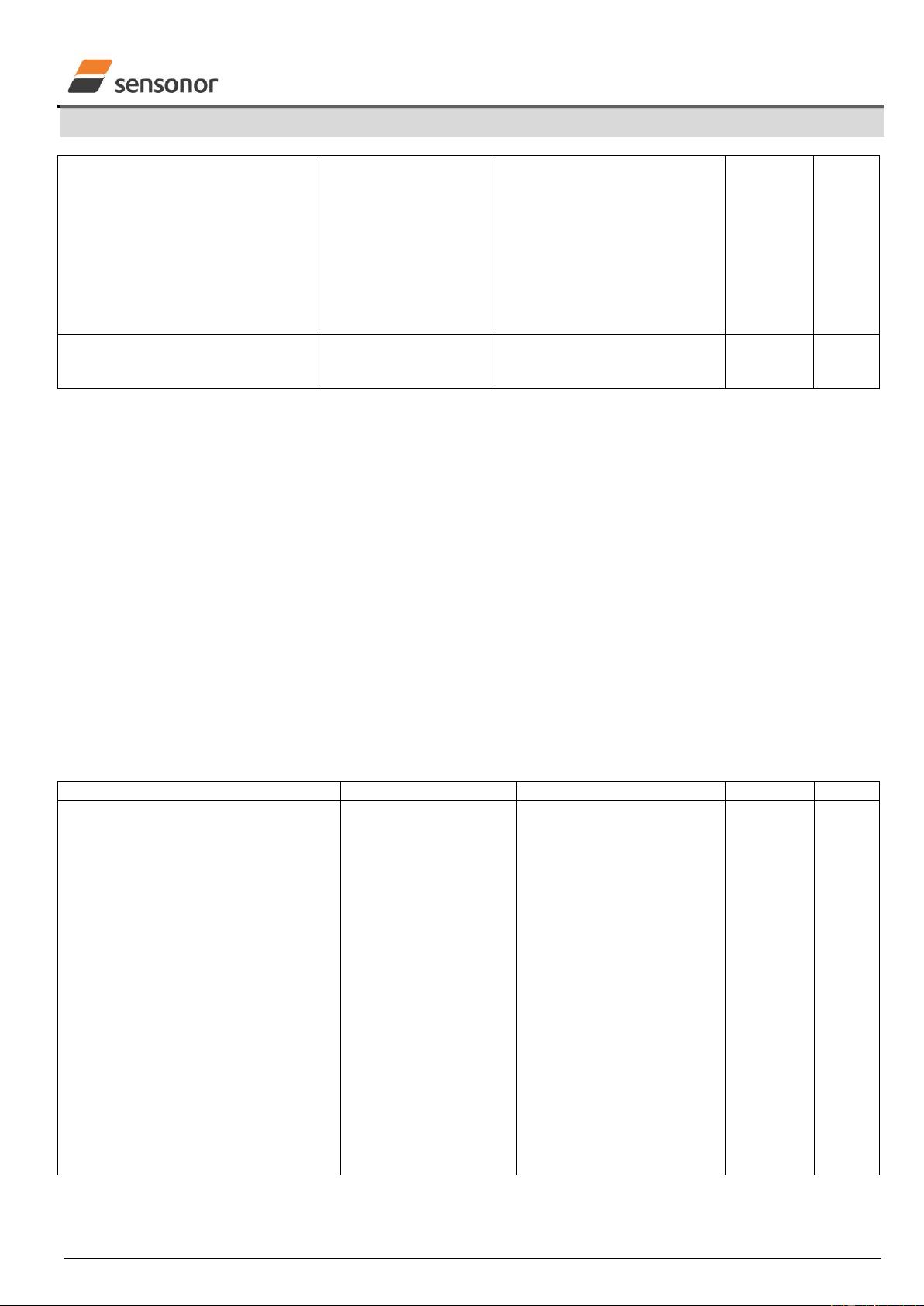

5 ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed in Table 5-1 may cause permanent damage to the device.

Exposure to any Absolute Maximum Rating condition for extended periods may affect device reliability and lifetime.

Table 5-1: Absolute maximum ratings

Parameter

Rating

Comment

Mechanical shock

1 500g/0.5ms half-sine

Any direction. Ref: MIL STD-883G

ESD human body model

±2kV

Ref: JEDEC/ESDA JS-001

Storage temperature

-55°C to +90°C

Up to 1000 hours

VSUP to GND

-0.5 to +7V

RxD+ or RxD- to GND

-0.3V to +7V

RxD+ to RxD-

±6V

with 120Ω Line Termination = ON

TxD+ or TxD- to GND

-8V to +8V

ExtTrig to GND

-0.3V to +7V

TOV to GND

-0.3V to +7V

NRST to GND

-0.3V to +7V

AUX+ to AUX-

±6.5V

AUX+ or AUX- to GND

±6.5V

Chassis to GND

Helium sensitivity

500V

Not to be exposed to helium concentrations higher

than those normally found in the atmosphere

DATASHEET

ButterflyGyro

™

STIM300 Inertia Measurement Unit

TS1524 rev.24 4/85 June 2018

6 SPECIFICATIONS

Table 6-1: Operating conditions

Parameter

Conditions

Min

Nom

Max

Unit

Note

INPUT RANGE, ANGULAR RATE

±400

°/s

INPUT RANGE, ACCELERATION

±10

g

1

INPUT RANGE, INCLINATION

±1.7

g

POWER SUPPLY

4.5

5.0

5.5

V

2,3

OPERATING TEMPERATURE

-40

+85

°C

Note 1: Other ranges available, ref. Table 6-5 (5g), Table 6-6 (30g) and Table 6-7 (80g)

Note 2: At supply voltages above 5.85V (nominal value) an internal voltage protection circuit will cut power and the unit

will go into reset until the voltage is back within operating conditions.

Note 3: At supply voltages below 4.05V (nominal value) the unit will go into reset until the voltage is back within

operating conditions. Due to power consumption being much lower in reset compared to normal operation, the

series resistance between power source and STIM300 could give rise to an oscillating behaviour of the input

voltage to the unit.

Table 6-2: Functional specifications, general

Parameter

Conditions

Min

Nom

Max

Unit

Note

POWER CONSUMPTION

Power consumption

1.5

2

W

TIMING

Start-Up time after Power-On

0.3

s

1

Time to transmit after Reset

0.2

s

2

Time to valid data

T=+25°C

0.7

1

s

s

3

3

RS422 Bit-Rate

ref. Table 6-11

RS422 Bit-Rate Accuracy

±1

%

4

RS422 PROTOCOL

Start Bit

1

bit

Data Length

8

bits

Parity

None

5

Stop Bits

1

bit

5

RS422 LINE TERMINATION

Input resistance

Line termination = ON

120

Ω

Input resistance

Line termination = OFF

48

125

kΩ

RESET (NRST PIN)

Logic levels

“high”

“low”

2.3

0.6

V

V

Minimum hold time for reset

1

µs

Pull-Up Resistor

80

100

kΩ

EXTERNAL TRIGGER (ExtTrig

PIN)

Logic levels

“high”

“low”

2.3

0.6

V

V

Trigger

Negative transition

Time between triggers

Measurement unit:

angular rate

0.5

127

ms

6,7

incremental angle

0.5

127

ms

6,8

average rate

0.5

65

ms

6,9

integrated angle

0.5

8

ms

6,10

Minimum “high” time before trigger,

t

ext_hi

250

ns

11

Minimum “low” time after trigger,

t

ext_lo

250

ns

11

Delay from external trigger to start

of transmission, t

ext_dl

86

µs

11

Pull-Up Resistor

40

50

kΩ

Latency

1000

µs

DATASHEET

ButterflyGyro

™

STIM300 Inertia Measurement Unit

TS1524 rev.24 5/85 June 2018

TIME OF VALIDITY (TOV PIN)

Output configuration

Open drain

Internal Pull-Up Resistor to Vsup

10

kΩ

Sink capability

50

mA

TOV active level

Active “low”

Minimum time of TOV, t

tov_min

50

µs

12

Delay from internal time-tick to

TOV active, t

tov_dl

1.2

6

µs

12

Delay from TOV active (to start of

transmission, t

tx_dl

80

µs

12

CHASSIS

Isolation resistance chassis to

GND (pin 15)

500V

100

MΩ

Note 1: Time from Power-On to start of datagram transmissions (starting with part-number datagram)

Note 2: Time from Reset release to start of datagram transmissions (starting with part-number datagram)

Note 3: Time from Power-On or Reset to the reset of the Start-Up bit (Bit 6 in the STATUS byte ref. Table 6-21).

During this period the output data should be regarded as non-valid.

Note 4: If a user-defined bit-rate larger than 1.5Mbit/s is used, the deviation may exceed the specification due to the

resolution of the bit-rate generator, ref. section 10.5.1

Note 5: Other values can be configured, ref. Table 6-11

Note 6: If time between triggers is longer than 127ms, the sample counter will over-run

Note 7: Time between triggers should be carefully evaluated as long time between triggers in combination with high

bandwidths could lead to issues related to folding. Similar for accelerometer and inclinometer outputs

Note 8: If time between triggers is longer than 8ms, an overload may occur in the incremental angle. An overload will

be flagged in the status byte, ref. Table 6-21. Similar for accelerometer and inclinometer outputs

Note 9: If time between triggers is longer, the accuracy of average rate may also be reduced. Similar for accelerometer

and inclinometer outputs

Note 10: If time between triggers is longer, the integrated angle may have wrapped several times and hence the

change in angle from last sample will not be possible to calculate. Similar for accelerometer and inclinometer

outputs

Note 11: For definition, ref. Figure 8-3

Note 12: For definition, ref. Figure 8-4 and Figure 8-5

Table 6-3: Functional specifications, gyros

Parameter

Conditions

Min

Nom

Max

Unit

Note

GYRO

Full Scale (FS)

±400

°/s

1

Resolution

24

0.22

bits

°/h

Scale Factor Accuracy

±500

ppm

Non-Linearity

±200°/s

±400°/s

15

20

ppm

ppm

2

2

Bandwidth (-3dB)

262

Hz

3

Sample Rate

2000

samples/s

4

Group Delay

LP-filter -3dB = 262Hz

LP-filter -3dB = 131Hz

LP-filter -3dB = 66Hz

LP-filter -3dB = 33Hz

LP-filter -3dB = 16Hz

1.5

3.0

6.0

12

24

ms

ms

ms

ms

ms

5

5

5

5

5

Bias Range

Bias Run-Run

Drift Rate Stability

Bias error over temperature

Bias error over temperature gradients

Static temperatures

ΔT ≤ ±1°C/min

-250

0

4

3

9

10

+250

°/h

°/h

°/h

°/h

°/h

6

7

Bias Instability

Allan Variance @25°C

0.3

°/h

Angular Random Walk

Allan Variance @25°C

0.15

°/√hr

剩余84页未读,继续阅读

资源评论

gdutjin

- 粉丝: 71

- 资源: 4

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- 线控转向系统:基于Carsim与Simulink联合仿真的控制策略与模型研究,线控转向系统:基于Carsim与Simulink联合仿真的控制策略与模型研究,线控转向系统联合仿真模型及控制策略研究 描述

- 基于python的订单管理系统

- 基于新算法SSA优化的变分模态分解风电功率分配策略:混合储能高效利用,创新性显著,基于新算法SSA优化的变分模态分解风电功率分配策略:混合储能高效利用与参数优化策略,基于新算法SSA优化变分模态分解的

- 【bussiness-DC】

- 使用BE、FE及C N方法求解一维扩散方程的Matlab实现,使用BE(向后欧拉)与FE(向前欧拉)算法及C N方法在Matlab中求解一维扩散方程的数值分析研究,使用BE(向后欧拉),FE(向前欧拉

- 博图16 PLC控制的4x5立体车库系统:包含运行效果视频、接线图及IO表全解析,4x5立体车库控制系统详解:博图16 PLC运行效果视频、接线图及IO表一览,4x5立体车库控制系统 博图16 带PL

- Python 智能机房签到系统:高效管理课堂考勤

- 进程上下文详细分析PDF原文

- 基于拉丁超立方采样与自适应核密度估计的电力系统概率潮流精准计算,基于拉丁超立方采样的电力系统概率潮流计算:自适应核密度估计与带宽优化的方法研究,采用拉丁超立方采样的电力系统概率潮流计算 (自适应核密度

- numpy-2.2.0-cp310-cp310-win32.whl

- numpy-2.2.0-cp310-cp310-win_amd64.whl

- 仅作测试无意义1111111111111111

- 基于PWM的 三色灯RGB模块调色 HAL库

- 商业数据分析BI+人工智能AI.zip

- 伺服驱动系统中的FPGA实现:电流环、速度环与位置环的协调控制,包含坐标变换及电机反馈接口,SVPWM技术,以及在FPGA中实现的编码器协议,伺服驱动FPGA电流环:实现坐标变换、电机反馈与SVPWM

- 基于PWM的 三色灯RGB模块调色 寄存器 代码

资源上传下载、课程学习等过程中有任何疑问或建议,欢迎提出宝贵意见哦~我们会及时处理!

点击此处反馈

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功