没有合适的资源?快使用搜索试试~ 我知道了~

Can calibration protocol (CCP)

温馨提示

该文档是汽车ECU标定中的协议文档如果你是做ECU标定的,该文档是基础哦.

资源推荐

资源详情

资源评论

ASAP Standard

CCP

CAN Calibration Protocol

Version 2.1

Version 2.1

Date 18. February 1999

Status Release

Author H. Kleinknecht

Distribution public

Co-Authors V2.1:

Andreas Krüger Hewlett Packard

Hans-Georg Kunz Mannesmann VDO

Ralf Maier ETAS

Hans Schröter Daimler-Benz

Rainer Zaiser Vector Informatik

ASAP Arbeitskreis zur Standardisierung von Applikationssystemen

Standardization of Application/Calibration Systems task force

representing

AUDI AG, BMW AG, Mercedes-Benz AG, Porsche AG, Volkswagen AG and

AVL List GesmbH, Robert Bosch GmbH, ETAS GmbH & Co. KG, Kleinknecht,

Siemens AG, Vector Informatik GmbH, Softing GmbH, VDO AG.

CAN Calibration Protocol

Version 2.1, 18-feb-99

Page i

Contents

1 Introduction.............................................................................................................1

1.1 ASAP................................................................................................................................................1

1.2 CAN Calibration Protocol (CCP)...................................................................................................1

2 Scope and field of application...............................................................................2

3 Related documents................................................................................................2

4 Revision history......................................................................................................2

5 Definitions and Abbreviations...............................................................................4

6 Protocol definition..................................................................................................5

6.1 Generic Control Commands.........................................................................................................5

6.2 Data Acquisition Commands........................................................................................................5

7 Message Objects....................................................................................................6

7.1 Organisation of Message Objects................................................................................................6

7.2 Description of Message Objects..................................................................................................7

7.2.1 Command Receive Object CRO..............................................................................................7

7.2.2 Data Transmission Object DTO...............................................................................................7

7.3 Organisation of Data Acquisition.................................................................................................9

8 Version Mechanism..............................................................................................12

9 Version compatibility...........................................................................................12

10 Table of Command Codes.................................................................................13

11 Table of Command Return Codes....................................................................14

12 Description of Commands.................................................................................15

12.1 Connect.......................................................................................................................................15

12.2 Exchange Station Identifications.............................................................................................16

12.3 Get Seed for Key........................................................................................................................18

12.4 Unlock Protection......................................................................................................................19

12.5 Set Memory Transfer Address..................................................................................................20

12.6 Data Download...........................................................................................................................21

12.7 Data Download 6 Bytes.............................................................................................................22

12.8 Data Upload................................................................................................................................23

12.9 Short Upload...............................................................................................................................24

12.10 Select Calibration Data Page..................................................................................................25

12.11Get Size of DAQ list..................................................................................................................26

12.12 Set DAQ list pointer.................................................................................................................27

CAN Calibration Protocol

Version 2.1, 18-feb-99

Page ii

12.13 Write DAQ list entry.................................................................................................................28

12.14 Start / Stop Data transmission................................................................................................29

12.15 Disconnect................................................................................................................................30

12.16 Set Session Status...................................................................................................................31

12.17 Get Session Status..................................................................................................................32

12.18 Build Checksum.......................................................................................................................33

12.19 Clear Memory...........................................................................................................................34

12.20 Program....................................................................................................................................35

12.21 Program 6 Bytes.......................................................................................................................36

12.22 Move memory block................................................................................................................37

12.23 Diagnostic Service...................................................................................................................38

12.24 Action Service..........................................................................................................................39

12.25 Test Availability........................................................................................................................40

12.26 Start / Stop Synchronised Data transmission......................................................................41

12.27 Get currently active Calibration Page...................................................................................42

12.28 Get implemented Version of CCP.........................................................................................43

13 Error Handling....................................................................................................44

14 Example Sequences...........................................................................................45

14.1 Session log-in.............................................................................................................................45

14.2 Block DownLoad........................................................................................................................45

14.3 Block UpLoad.............................................................................................................................45

14.4 Calibration Data Initialization....................................................................................................46

14.5 DAQ List Initialization................................................................................................................46

14.6 Code Update...............................................................................................................................46

15 Expected Performance Ratings........................................................................47

16 Appendices.........................................................................................................48

16.1 Matrix of Error Codes................................................................................................................48

16.2 Broadcast Techniques in Multi-point Applications................................................................49

CAN Calibration Protocol

Version 2.1, 18-feb-99

Page 1

11 IntroductionIntroduction

1.11.1 ASAPASAP

The ASAP task force (Arbeitskreis zur Standardisierung von Applikationssystemen; English

translation: Standardization of Application/Calibration Systems task force) has been

founded by the companies Audi AG, BMW AG, Mercedes-Benz AG, Porsche AG and

Volkswagen AG. European manufacturers of automation, test and development systems for

the automotive industry as well as manufacturers of electronic control units have joined this

task force.

The world of automotive technology has grown into complex electronic system

configurations to meet the increased requirements in the area of legislated exhaust gas

limits, environmental pollution protection, security systems, driving performance and body

equipment options. Some automotive manufacturers use in vehicle distributed control

systems supported by networks.

To develop this new generation of automotive electronics, new and high sophisticated

software, calibration, measurement and diagnosis equipment has to be used. At this time

almost no standards exist in the area of software interfaces for such devices. Each

company has its proprietary systems and interfaces to support the development of these

high end configurations.

Therefore, the mission of ASAP is to reach mutual agreement and standardization in

• automation, modularisation and compatibility of all equipment to do measurement,

calibration and diagnosis, and

• manage the creation of a cost reasonable and sensible tool supplier market.

1.21.2 CAN Calibration Protocol (CCP)CAN Calibration Protocol (CCP)

The Controller Area Network CAN is a joint development of Robert Bosch GmbH and Intel

Corporation. CAN is used in many high-end automotive control systems like engine

management as well as in industrial control systems. Controller chips for CAN are available

from various semiconductor manufacturers.

The CAN Calibration Protocol is part of the ASAP standards. It was developed and

introduced by Ingenieurbüro Helmut Kleinknecht, a manufacturer of calibration systems,

and is used in several applications in the automotive industry. The CCP was taken over by

the ASAP working group and enhanced with optional functions.

CAN Calibration Protocol

Version 2.1, 18-feb-99

Page 2

22 Scope and field of applicationScope and field of application

This document specifies the CAN Calibration Protocol CCP, as defined by the work group

within the ASAP task force.

The CCP defines the communication of controllers with a master device using the CAN

2.0B (11-bit and 29-bit identifier), which includes 2.0A (11-bit identifier) for

1. data acquisition from the controllers,

2. memory transfers to and control functions in the controllers for calibration.

Providing these functions the CCP may be used in the areas of

• development of electronic control units (ECU)

• systems for functional and environmental tests of an ECU,

• test systems and test stands for the controlled devices (combustion engines,

gearboxes, suspension systems, climatic control systems, body systems, anti-locking

systems),

• on-board test and measurement systems of pre-series vehicles, and

• any non-automotive application of CAN-based distributed electronic control systems.

33 Related documentsRelated documents

Specifications and data sheets from Intel Corporation:

• 82527 Serial Communications Controller Datasheet (Intel #272250)

• 82527 Serial Communications Controller Architectural Overview (Intel #272410)

• Introduction to the Controller Area Network (CAN) Protocol (Intel #270962)

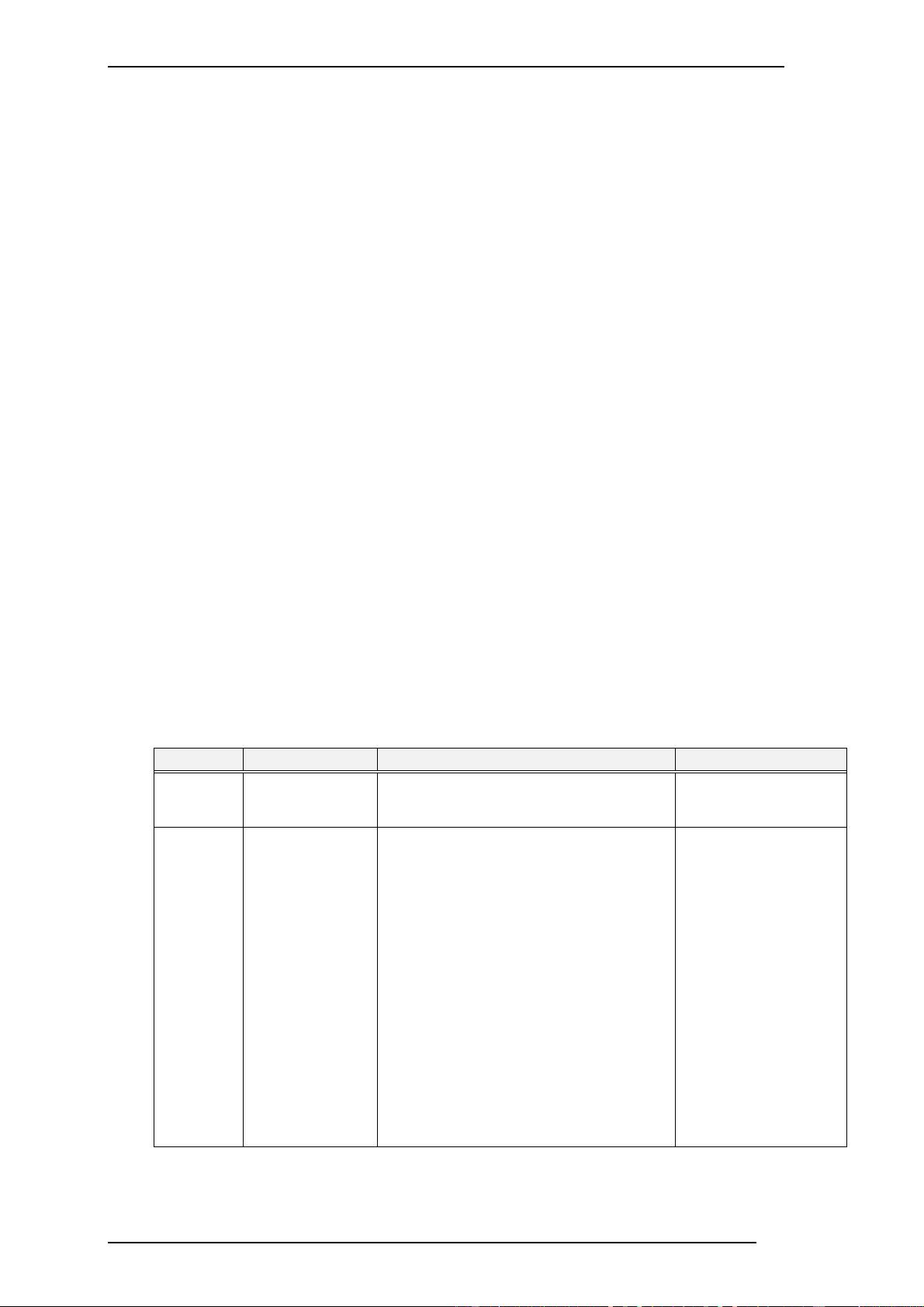

44 Revision historyRevision history

Revision Date Item(s) changed Note

1.0 30 - Sep - 1992 Initial release from

Ingenieurbüro Helmut

Kleinknecht

1.01b 07 - Dec - 1995 Working draft, with the following optional

commands added

- EXCHANGE_ID

- GET_SEED

- UNLOCK

- GET_DAQ_SIZE

- SET_DAQ_PTR

- WRITE_DAQ

- ACTION_SERVICE

and the return / error codes

- Key request

- Session status request

- Cold start request

- Cal. data init. request

- DAQ list init. request

- code update request

- access locked

ASAP work group

剩余51页未读,继续阅读

chengbaoshu2006

- 粉丝: 1

- 资源: 1

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- 基于Jupyter Notebook的AI学习理论与应用实战源码

- 基于高频信号注入的三相永磁同步电机无传感器控制与Matlab仿真研究,基于高频信号注入的三相永磁同步电机无传感器控制与Matlab仿真研究,基于高频信号注入的三相永磁同步电机无传感器控制仿真;旋转电压

- 三次B样条优化:独立子程序,适用于所有Matlab程序,直接优化使用指南,三次B样条优化独立子程序,适用于所有Matlab程序,一键提升程序性能,3次B样条优化,适用于所有matlab程序,单独的独立

- 基于主从博弈与粒子群算法的电热综合能源系统动态定价与能量管理优化模型,基于主从博弈的电热综合能源系统动态定价策略与能量管理优化模型研究-MATLAB实现与CPLEX求解器应用,MATLAB代码:基于

- 基于Cruise软件的增程混动仿真模型:功率跟随控制策略详解与串联混动汽车动力经济性仿真探究,基于Cruise软件的增程混动仿真模型:功率跟随控制策略详解与串联混动汽车动力经济性仿真探究,cruise

- 日前日内两阶段调度综合能源分析:基于Matlab与Yalmip的优化结果对比及机组成本与弃风惩罚的探讨,日前日内两阶段调度综合能源分析:基于Matlab与Yalmip的优化结果对比及机组成本与弃风惩罚

- 西门子新能源四轴自动排列机:基于RFID与MES通讯的V90控制程序,详细注释与CAD电气图,适合初学者进阶参考,西门子新能源四轴自动排列机V14全解析:轴控制、RFID读写与MES通讯全攻略,西门子

- 基于Html+JavaScript的结婚请柬设计源码示例demo

- 日前日内两阶段调度综合能源分析:基于Matlab与Yalmip的程序优化结果对比及成本考量,基于Matlab与Yalmip编程的综合能源调度策略对比:考虑需求响应与弃风惩罚的日前日内两阶段调度研究,日

- C# Windows窗口开发实战:图书管理系统的设计与实现,包括详细文档介绍,基于C#的Windows窗口图书管理系统:功能介绍与文档指南,C# Windows窗口,图书管理系统 包含文档介绍 ,C#

- 三菱FX3U与两台变频器Modbus RTU通讯CRC程序详解:实现正反转控制、频率读写及电压电流监控,三菱FX3U与两台变频器Modbus RTU通讯CRC程序详解:控制正反转、频率写入与读取、电压

- 《自研电动汽车永磁电机后驱模型:8极48槽配置与性能分析手册》,电动汽车永磁电机后驱模型:搭建、性能分析与效率优化,某整车厂电动汽车永磁电机后驱模型,8极48槽配合,自己一手搭建,可以分析出电机基本性

- 西门子1200脉冲运动控制块:便捷调用,多种功能,博途西门子v15以上兼容,省心高效实现轴控制,西门子1200脉冲运动控制块:高效便捷,实现多种运动模式与轻松调试,适用于博途西门子v15及以上版本,西

- 基于Python技术的社区医疗老年人体检项目设计源码

- 燃料电池多点恒功率工作Cruise与Matlab联合仿真模型介绍及功能实现,燃料电池多点恒功率工作Cruise仿真模型的设计与实现(基于Cruise 2019与Matlab Simulink联合开发)

- 基于纳什谈判理论的风-光-氢多主体能源系统协同合作运行仿真方法研究,基于纳什谈判理论的风光氢多主体能源系统协同运行策略MATLAB实现,MATLAB代码:基于纳什谈判理论的风–光–氢多主体能源系统合作

资源上传下载、课程学习等过程中有任何疑问或建议,欢迎提出宝贵意见哦~我们会及时处理!

点击此处反馈

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功

- 1

- 2

前往页