Building Programmable Automation Controllers with LabVIEW

FPGA

Overview

Programmable Automation Controllers (PACs) are gaining acceptance within the

industrial control market as the ideal solution for applications that require highly integrated

analog and digital I/O, floating-point processing, and seamless connectivity to multiple

processing nodes. National Instruments offers a variety of PAC solutions powered by one

common software development environment, NI LabVIEW. With LabVIEW, you can build

custom I/O interfaces for industrial applications using add-on software, such as the NI

LabVIEW FPGA Module.

With the LabVIEW FPGA Module and reconfigurable I/O (RIO) hardware, National

Instruments delivers an intuitive, accessible solution for incorporating the flexibility and

customizability of FPGA technology into industrial PAC systems. You can define the logic

embedded in FPGA chips across the family of RIO hardware targets without knowing low-

level hardware description languages (HDLs) or board-level hardware design details, as well

as quickly define hardware for ultrahigh-speed control, customized timing and

synchronization, low-level signal processing, and custom I/O with analog, digital, and

counters within a single device. You also can integrate your custom NI RIO hardware with

image acquisition and analysis, motion control, and industrial protocols, such as CAN and

RS232, to rapidly prototype and implement a complete PAC system.

Table of Contents

1. Introduction

2. NI RIO Hardware for PACs

3. Building PACs with LabVIEW and the LabVIEW FPGA Module

4. FPGA Development Flow

5. Using NI SoftMotion to Create Custom Motion Controllers

6. Applications

7. Conclusion

Introduction

You can use graphical programming in LabVIEW and the LabVIEW FPGA Module to

configure the FPGA (field-programmable gate array) on NI RIO devices. RIO technology, the

merging of LabVIEW graphical programming with FPGAs on NI RIO hardware, provides a

flexible platform for creating sophisticated measurement and control systems that you could

previously create only with custom-designed hardware.

An FPGA is a chip that consists of many unconfigured logic gates. Unlike the fixed,

vendor-defined functionality of an ASIC (application-specific integrated circuit) chip, you can

configure and reconfigure the logic on FPGAs for your specific application. FPGAs are used

in applications where either the cost of developing and fabricating an ASIC is prohibitive, or

the hardware must be reconfigured after being placed into service. The flexible, software-

programmable architecture of FPGAs offer benefits such as high-performance execution of

custom algorithms, precise timing and synchronization, rapid decision making, and

simultaneous execution of parallel tasks. Today, FPGAs appear in such devices as

instruments, consumer electronics, automobiles, aircraft, copy machines, and application-

specific computer hardware. While FPGAs are often used in industrial control products,

FPGA functionality has not previously been made accessible to industrial control engineers.

Defining FPGAs has historically required expertise using HDL programming or complex

design tools used more by hardware design engineers than by control engineers.

With the LabVIEW FPGA Module and NI RIO hardware, you now can use LabVIEW, a

high-level graphical development environment designed specifically for measurement and

control applications, to create PACs that have the customization, flexibility, and high-

performance of FPGAs. Because the LabVIEW FPGA Module configures custom circuitry in

hardware, your system can process and generate synchronized analog and digital signals

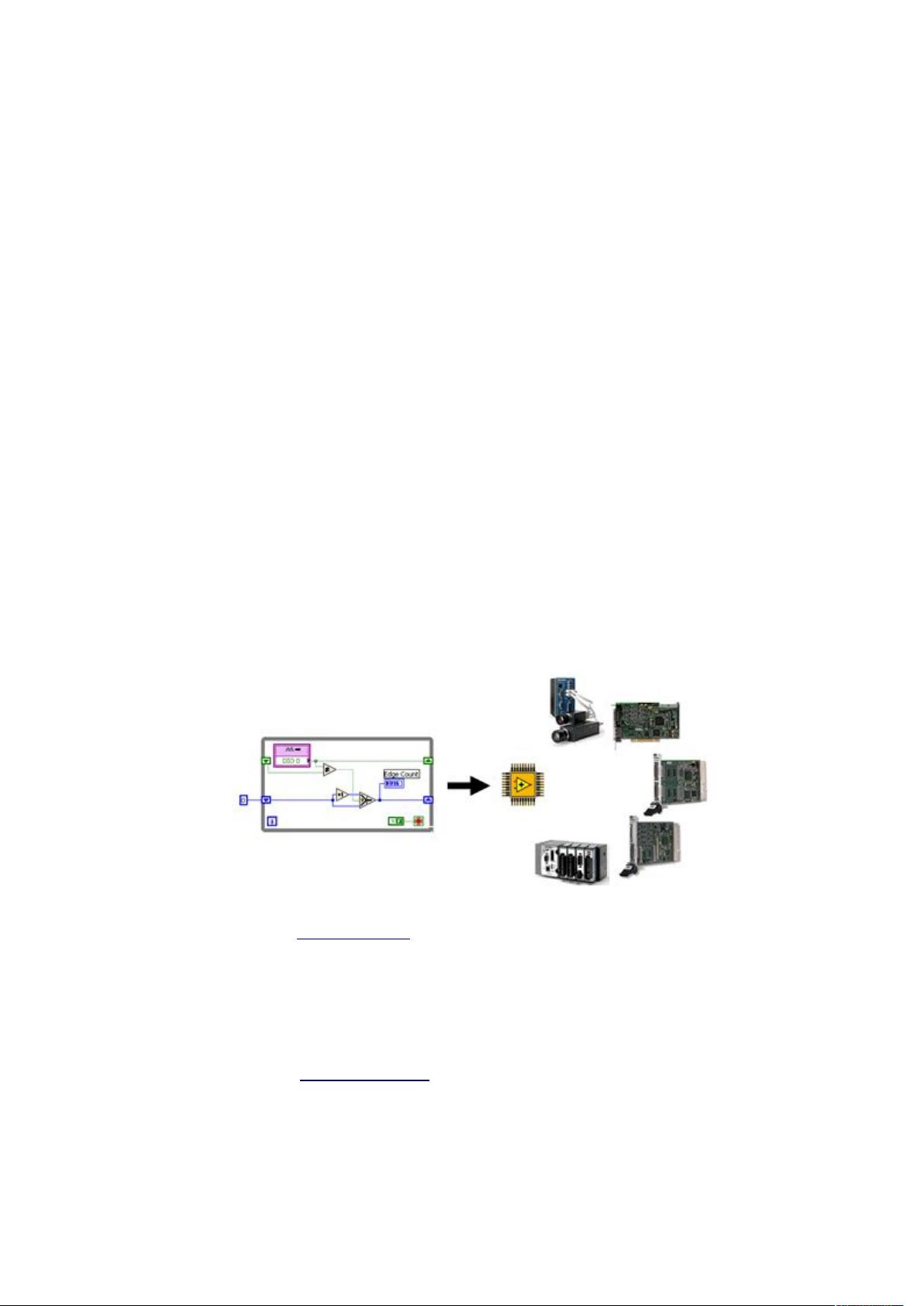

rapidly and deterministically. Figure 1 illustrates many of the NI RIO devices that you can

configure using the LabVIEW FPGA Module.

Figure 1. LabVIEW FPGA VI Block Diagram and RIO Hardware Platforms

NI RIO Hardware for PACs

Historically, programming FPGAs has been limited to engineers who have in-depth

knowledge of VHDL or other low-level design tools, which require overcoming a very steep

learning curve. With the LabVIEW FPGA Module, NI has opened FPGA technology to a

broader set of engineers who can now define FPGA logic using LabVIEW graphical

development. Measurement and control engineers can focus primarily on their test and control

application, where their expertise lies, rather than the low-level semantics of transferring logic

into the cells of the chip. The LabVIEW FPGA Module model works because of the tight

integration between the LabVIEW FPGA Module and the commercial off-the-shelf (COTS)

hardware architecture of the FPGA and surrounding I/O components.

National Instruments PACs provide modular, off-the-shelf platforms for your industrial

control applications. With the implementation of RIO technology on PCI, PXI, and Compact

Vision System platforms and the introduction of RIO-based CompactRIO, engineers now

have the benefits of a COTS platform with the high-performance, flexibility, and

customization benefits of FPGAs at their disposal to build PACs. National Instruments PCI

and PXI R Series plug-in devices provide analog and digital data acquisition and control for

high-performance, user-configurable timing and synchronization, as well as onboard decision

making on a single device. Using these off-the-shelf devices, you can extend your NI PXI or

PCI industrial control system to include high-speed discrete and analog control, custom sensor

interfaces, and precise timing and control.

NI CompactRIO, a platform centered on RIO technology, provides a small, industrially

rugged, modular PAC platform that gives you high-performance I/O and unprecedented

flexibility in system timing. You can use NI CompactRIO to build an embedded system for

applications such as in-vehicle data acquisition, mobile NVH testing, and embedded machine

control systems. The rugged NI CompactRIO system is industrially rated and certified, and it

is designed for greater than 50 g of shock at a temperature range of -40 to 70 °C.

NI Compact Vision System is a rugged machine vision package that withstands the harsh

environments common in robotics, automated test, and industrial inspection systems. NI

CVS-145x devices offer unprecedented I/O capabilities and network connectivity for

distributed machine vision applications.NI CVS-145x systems use IEEE 1394 (FireWire)

technology, compatible with more than 40 cameras with a wide range of functionality,

performance, and price. NI CVS-1455 and NI CVS-1456 devices contain configurable

FPGAs so you can implement custom counters, timing, or motor control in your machine

vision application.

Building PACs with LabVIEW and the LabVIEW FPGA Module

With LabVIEW and the LabVIEW FPGA Module, you add significant flexibility and

customization to your industrial control hardware. Because many PACs are already

programmed using LabVIEW, programming FPGAs with LabVIEW is easy because it uses

the same LabVIEW development environment. When you target the FPGA on an NI RIO

device, LabVIEW displays only the functions that can be implemented in the FPGA, further

easing the use of LabVIEW to program FPGAs. The LabVIEW FPGA Module Functions

palette includes typical LabVIEW structures and functions, such as While Loops, For Loops,

Case Structures, and Sequence Structures as well as a dedicated set of LabVIEW FPGA-

specific functions for math, signal generation and analysis, linear and nonlinear control,

comparison logic, array and cluster manipulation, occurrences, analog and digital I/O, and

timing. You can use a combination of these functions to define logic and embed intelligence

onto your NI RIO device.

Figure 2 shows an FPGA application that implements a PID control algorithm on the NI

RIO hardware and a host application on a Windows machine or an RT target that

communicates with the NI RIO hardware. This application reads from analog input 0 (AI0),

performs the PID calculation, and outputs the resulting data on analog output 0 (AO0). While

the FPGA clock runs at 40 MHz the loop in this example runs much slower because each

component takes longer than one-clock cycle to execute. Analog control loops can run on an

FPGA at a rate of about 200 kHz. You can specify the clock rate at compile time. This

example shows only one PID loop; however, creating additional functionality on the NI RIO

device is merely a matter of adding another While Loop. Unlike traditional PC processors,

FPGAs are parallel processors. Adding additional loops to your application does not affect the

performance of your PID loop.

Figure 2. PID Control Using an Embedded LabVIEW FPGA VI with Corresponding LabVIEW Host

VI.

FPGA Development Flow

After you create the LabVIEW FPGA VI, you compile the code to run on the NI RIO

hardware. Depending on the complexity of your code and the specifications of your

development system, compile time for an FPGA VI can range from minutes to several hours.