AVR450: Battery Charger for SLA, NiCd, NiMH

and Li-Ion Batteries

Features

• Complete Battery Charger Design

• Modular “C” Source Code and Extremely Compact Assembly Code

• Low Cost

• Supports Most Common Battery Types

• Fast Charging Algorithm

• High Accuracy Measurement with 10-bit A/D Converter

• Optional Serial Interface

• Easy Change of Charge Parameters

• EEPROM for Storage of Battery Characteristics

1 Introduction

The battery charger reference design is a battery charger that fully implements the

latest technology in battery charger designs. The charger can fast-charge all

popular battery types without any hardware modifications. It allows a full product

range of chargers to be built around a single hardware design; a new charger

model is designed simply by reprogramming the desired charge algorithm into the

microcontroller using In-System Programmable Flash memory. This allows

minimum time to market for new products and eliminates the need to stock more

than one version of the hardware. The charger design contains complete libraries

for SLA, NiCd, NiMH, and Li-Ion batteries.

Figure 1-1. Battery Charger Reference Design Board

8-bit

Microcontrollers

Application Note

1659C-AVR-09/06

2

AVR450

1659C-AVR-09/06

The battery charger reference design includes two battery chargers built with the

high-end AT90S4433 microcontroller and the highly integrated low-cost 8-pin

ATtiny15 microcontroller. However, it can be implemented using any AVR

microcontroller with A/D converter, PWM output and enough program memory to

store the desired charging algorithm.

As more and more electronic equipment becomes portable, the rush for better

batteries with higher capacity, smaller size and lower weight will increase. The

continuing improvements in battery technology calls for more sophisticated charging

algorithms to ensure fast and secure charging. Higher accuracy monitoring of the

charge process is required to minimize charge time and utilize maximum capacity of

the battery while avoiding battery damage. The AVR

®

microcontrollers are one step

ahead of the competition, proving perfect for the next generation of chargers.

The Atmel AVR microcontroller is the most efficient 8-bit RISC microcontroller in the

market today that offers Flash, EEPROM, and 10-bits A/D converter in one chip.

Flash program memory eliminates the need to stock microcontrollers with multiple

software versions. Flash can be efficiently programmed in production just before

shipping the finished product. Programming after mounting is made possible through

fast In-System Programming (ISP), allowing up-to-date software and last minute

modifications.

The EEPROM data memory can be used for storing calibration data and battery

characteristics, it also allows charging history to be permanently recorded, allowing

the charger to optimize for improved battery capacity. The integrated 10-bit A/D

converter gives superior resolution for the battery measurements compared to other

microcontroller-based solutions. Improved resolution allows charging to continue

closer to the maximum capacity of the battery. Improved resolution also eliminates

the need for external op-amps to “window” the voltage. The result is reduced board

space and lower system cost.

AVR is the only 8-bit microcontroller designed for high-level languages like “C”. The

reference design for AT90S4433 is written entirely in “C”, demonstrating the superior

simplicity of software design in high-level languages. C-code makes this reference

design easy to adopt and modify for today’s and tomorrows batteries. The reference

design for ATtiny15 is written in assembly to achieve maximum code density.

2 Theory of Operation

The charging of a battery is made possible by a reversible chemical reaction that

restores energy in a chemical system. Depending on the chemicals used, the battery

will have certain characteristics. When designing a charger, a detailed knowledge of

these characteristics is required to avoid damage inflicted by overcharging.

2.1 The AVR 8-bit RISC MCU

The reference designs includes two separate battery chargers. One using

AT90S4433 AVR microcontroller and one using the ATtiny15 AVR microcontroller.

The AT90S4433 design demonstrates how efficient a battery charger can be

implemented with C-code. The ATtiny15 design shows the highest integrated and

lowest cost battery charger available in today’s market. The AT90S4433 can be used

for voltage and temperature monitoring with UART interface to PC for data logging.

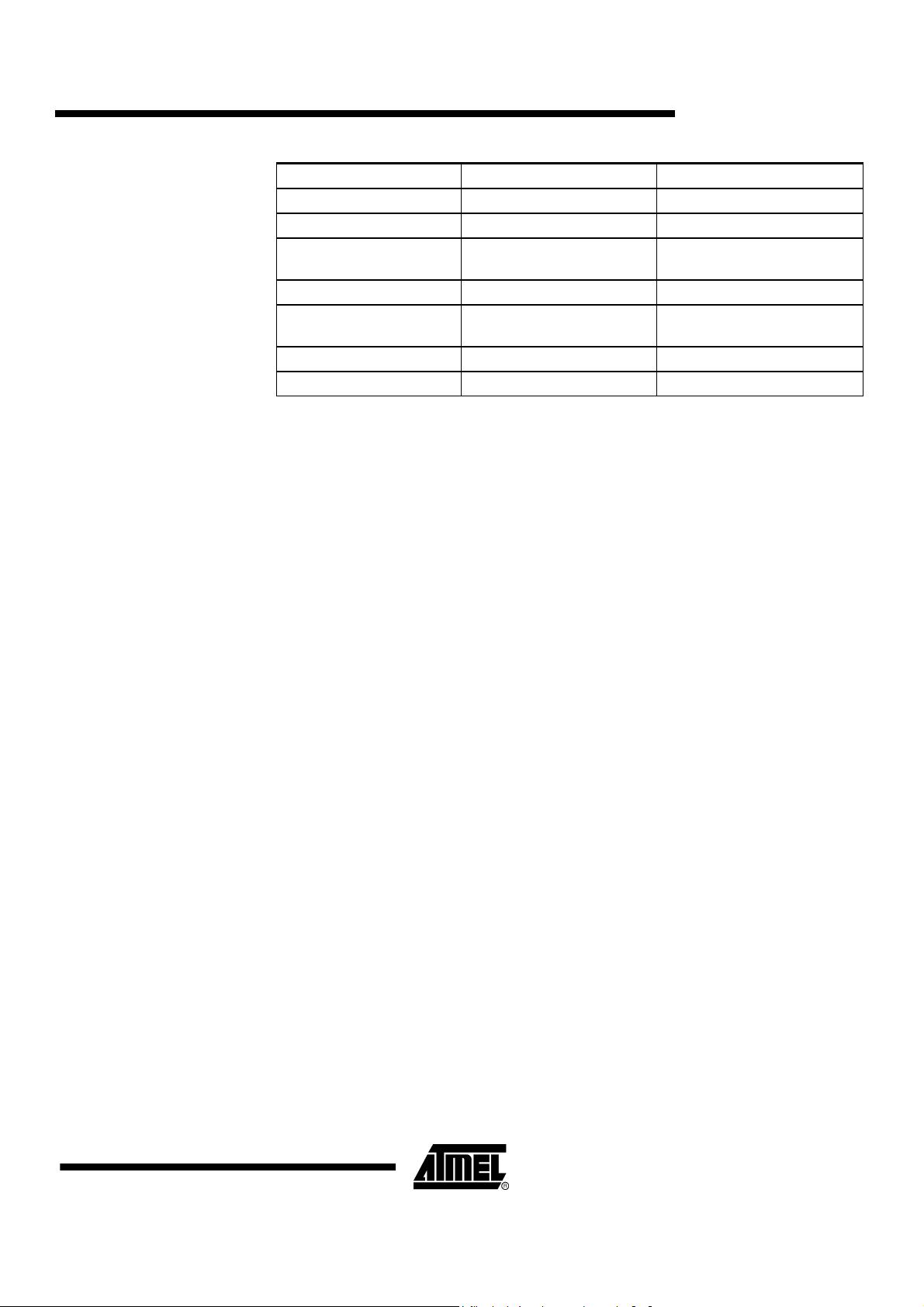

Table 1 shows the differences in the design.

AVR450

3

1659C-AVR-09/06

Table 2-1. Design Differences

AT90S4433 Design ATtiny15 Design

Programming Language C Assembly

Code Size (approximately) 1.5K Bytes <350 Bytes

Current Measurement

External Op-Amp Gain

Stage

Built-in Differential Gain Stage

PWM Frequency 14 kHz, 8-bit Resolution 100 kHz, 8-bit Resolution

Clock Source External Crystal, 7.3 MHz

Internal Calibrated RC

Oscillator, 1.6 MHz

Serial Comm. Interface Yes No

In-System Programming Yes Yes

2.2 Battery Technologies

Modern consumer electronics use mainly four different types of rechargeable

batteries:

• Sealed Lead Acid (SLA)

• Nickel Cadmium (NiCd)

• Nickel Metal Hydride (NiMH)

• Lithium-Ion (Li-Ion)

It is important to have some background information on these batteries to be able to

select the right battery and charging algorithm for the application.

2.2.1 Sealed Lead Acid (SLA)

Sealed Lead Acid batteries are used in many applications where cost is more

important than space and weight, typically preferred as backup batteries for UPS and

alarm-systems. The SLA batteries are charged using constant voltage, with a current

limiter to avoid overheating in the initial stage of the charging process. SLA batteries

can be charged infinitely, as long at the cell voltage never exceeds the manufacturer

specifications (typically 2.2V).

2.2.2 Nickel Cadmium (NiCd)

Nickel Cadmium batteries are widely used today. They are relatively cheap and

convenient to use. A typical NiCd cell can be fully charged up to 1,000 times. They

have a high self-discharge rate. NiCd batteries are damaged from being reversed,

and the first cell to discharge completely in a battery pack will be reversed. To avoid

damaging discharge of a battery pack, the voltage should be constantly monitored

and the application should be shutdown when the cell voltage drops below 1.0V. NiCd

batteries are charged with constant current.

2.2.3 Nickel Metal Hydride (NiMH)

Nickel Metal Hydride batteries are the most widely used battery type in new

lightweight portable applications (i.e., cell phones, camcorders, etc.). They have a

higher energy density than NiCd. NiMH batteries are damaged from overcharging. It

is therefore important to do accurate measurements to terminate the charging at

exactly the right time (i.e., fully charge the battery without overcharging). Like NiCd,

NiMH batteries are damaged from being reversed.

4

AVR450

1659C-AVR-09/06

NiMH has a self-discharge rate of approximately 20%/ month. Like NiCd batteries,

NiMH batteries are charged with constant current.

2.2.4 Lithium-Ion (Li-Ion)

Lithium-Ion batteries have the highest energy/weight and energy/space ratio

compared to the other batteries in this application note. Li-Ion batteries are charged

using constant voltage, with current limiter to avoid overheating in the initial stage of

the charging process. The charging is terminated when the charging current drops

below the lower current limit set by the manufacturer. The battery takes damage from

overcharging and may explode when overcharged.

2.3 Safe Charging of Batteries

Modern fast chargers (i.e., battery fully charged in less than three hours, normally one

hour) requires accurate measurements of the cell voltage, charging current and

battery temperature in order to fully charge the battery completely without

overcharging or otherwise damage it.

2.3.1 Charge Methods

SLA and Li-Ion batteries are charged with constant voltage (current limited). NiCd and

NiMH batteries are charged with constant current and have a set of different

termination methods.

2.3.2 Maximum Charge Current

The maximum charge current is dependent on the battery capacity (C). The maximum

charge current is normally given in amounts of the battery capacity. For example, a

battery with a cell capacity of 750 mAh charged with a charging current of 750 mA is

referred to as being charged at 1C (1 times the battery capacity). If the charging

current for trickle-charge is set to be C/40 the charging current is the cell capacity

divided by 40.

2.3.3 Overheating

By transferring electric energy into a battery, the battery is charged. This energy is

stored in a chemical process. But not all the electrical energy applied to the battery is

transformed into the battery as chemical energy. Some of the electrical energy ends

up as thermal energy, heating up the battery. When the battery is fully charged, all the

electrical energy applied to the battery ends up as thermal energy. On a fast charger,

this will rapidly heat up the battery, inflicting damage to the battery if the charging is

not terminated. Monitoring the temperature to terminate the charging is an important

factor in designing a good battery charger.

2.4 Termination Methods

The application and environment where the battery is used sets limitations on the

choice of termination method. Sometimes it might be impractical to measure the

temperature of the battery and easier to measure the voltage, or the other way

around. This reference design implements the use of voltage drop (-dV/dt) as primary

termination method, with temperature and absolute voltage as backup. But the

hardware supports all of the below mentioned methods.

AVR450

5

1659C-AVR-09/06

2.4.1 t – Time

This is one of the simplest ways to measure when to terminate the charging. Normally

used as backup termination when fast-charging. Also used as primary termination

method in normal charging (14 - 16h). Applies to all batteries.

2.4.2 V – Voltage

Charging is terminated when the voltage rises above a preset upper limit. Used in

combination with constant current charging. Maximum current is determined by the

battery, usually 1C as described above. Current limiting is crucial to avoid thermal

damage to the battery if charge current is too high. SLA batteries are normally

charged infinitely by setting the maximum voltage above the actual charge voltage.

Used for Li-Ion as primary charging algorithm/termination method. Li-Ion chargers

usually continue with a second phase after the maximum voltage has been reached

to safely charge the battery to 100%. Also used on NiCd and NiMH as backup

termination.

2.4.3 -dV/dt – Voltage Drop

This termination method utilizes the negative derivative of voltage over time,

monitoring the voltage drop occurring in some battery types if charging is continued

after the battery is fully charged. Commonly used with constant current charging.

Applies to fast-charging of NiCd and NiMH batteries.

2.4.4 I – Current

Charging is terminated when the charge current drops below a preset value.

Commonly used with constant voltage charging. Applies to SLA and Li-Ion to

terminate the top-off charge phase usually following the fast-charge phase.

2.4.5 T – Temperature

Absolute temperature can be used as termination (for NiCd and NiMH batteries), but

is preferred as backup termination method only. Charging of all batteries should be

terminated if the temperature rises above the operating temperature limit set by the

manufacturer. Also used as a backup method to abort charging if voltage drops below

a safe temperature – Applies to all batteries.

2.4.6 dT/dt – Temperature Rise

The derivative of temperature over time can be used as termination method when

fast-charging. Refer to the manufacturer’s specifications on information on the exact

termination point (Typically 1C/min for NiCd batteries) – Applies to NiCd and NiMH.

2.4.7 DT – Temperature over Ambient Temperature

Terminates charging when the difference between ambient (room) temperature and

battery temperature rises over a preset threshold level. Applies to NiCd and SLA as

primary or backup termination method. Preferred over absolute temperature to avoid

battery damage when charged in a cold environment. As most systems have only one

temperature probe available, the ambient temperature is usually measured before

charging is initiated.