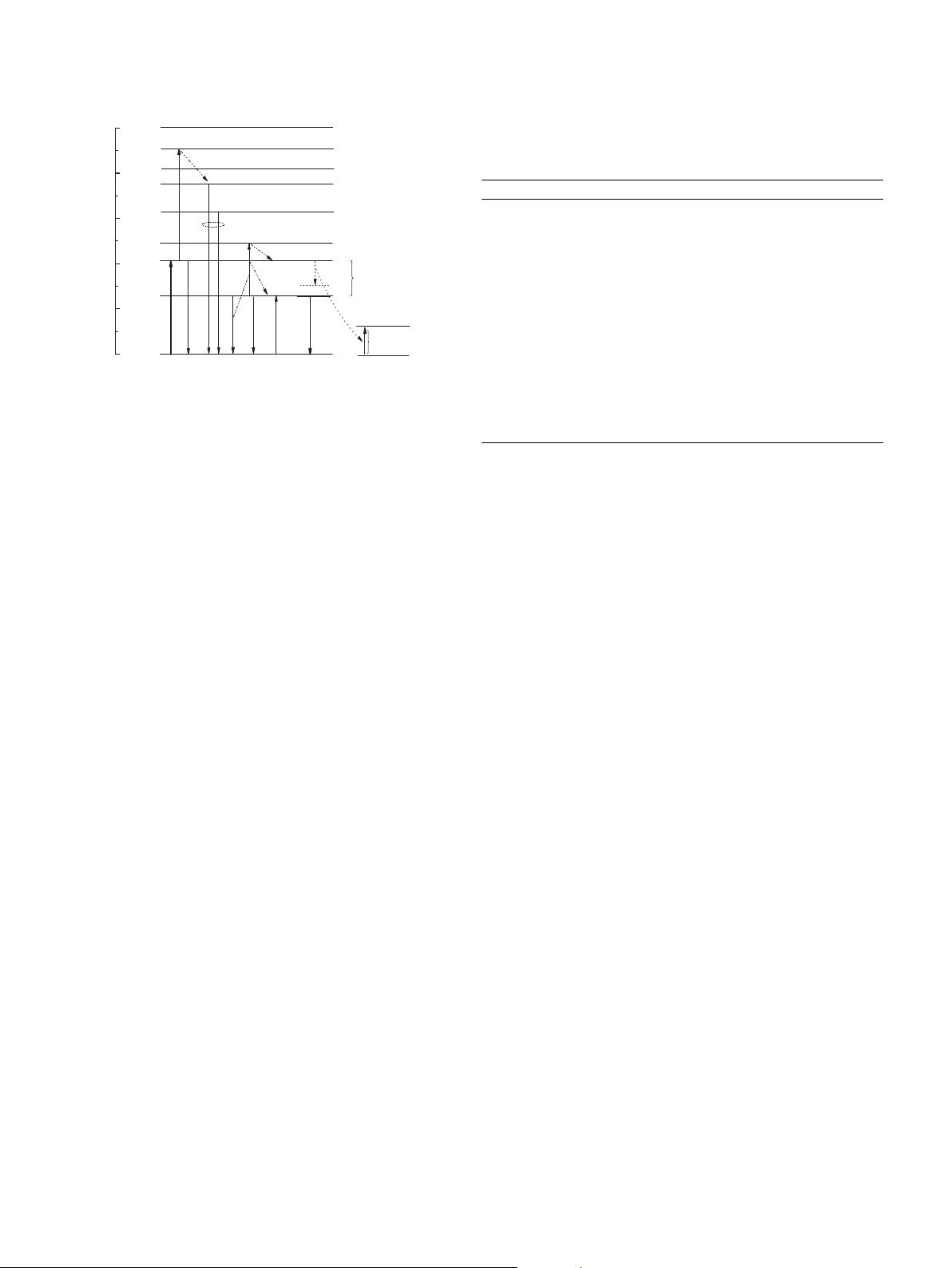

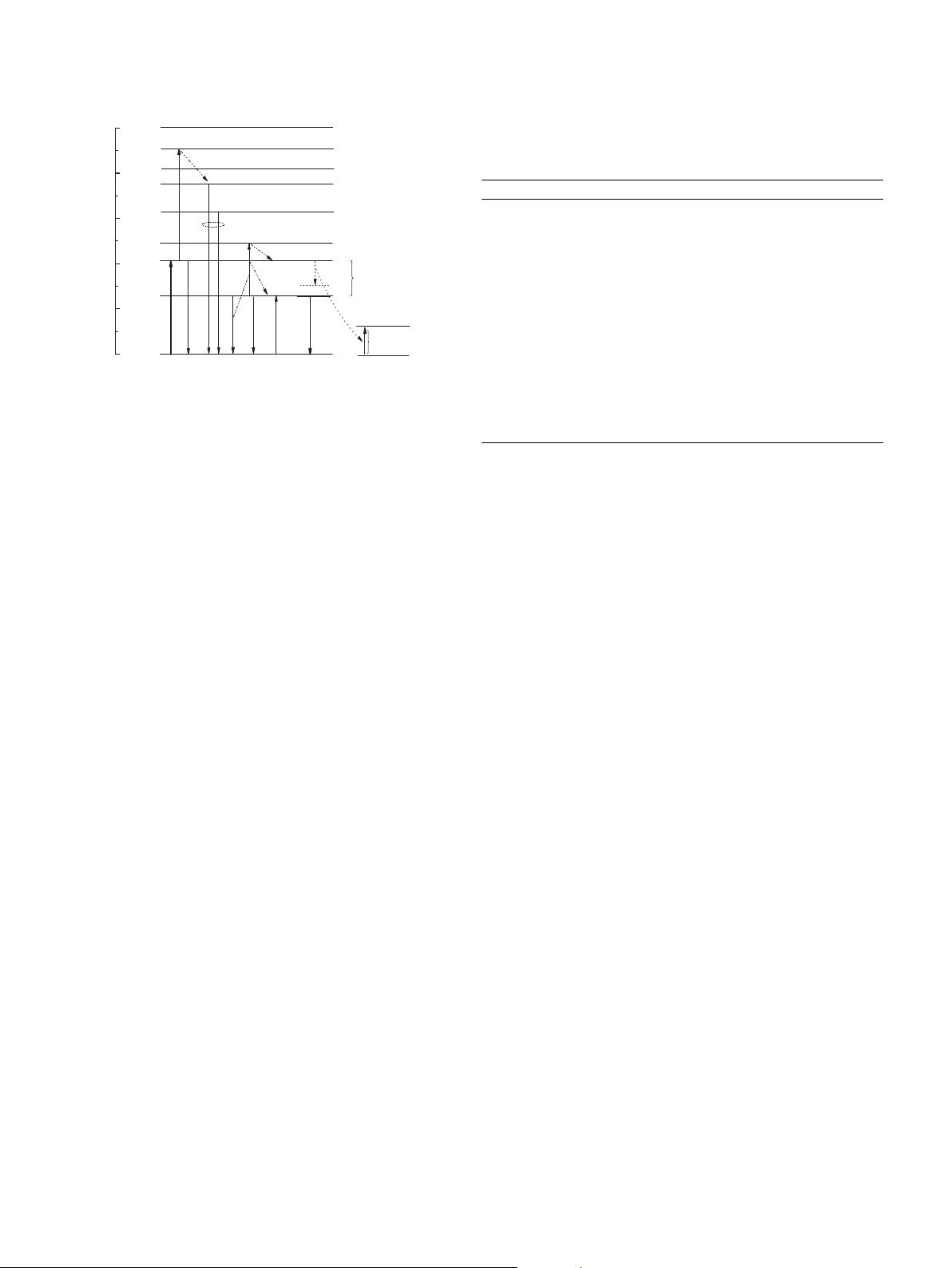

2

F

7/2

and

2

F

5/2

levels for Ce

3+

ions is about 2200 cm

1

while that for

Er

3+

ions between

4

I

11/2

and

4

I

13/2

levels is about 3600 cm

1

[15,16], which is depicted in Fig. 1, indicating that one or more

phonons of glass host will be needed to compensate this energy

difference in the realization of above ET process. Obviously, the

glass host with large phonon energy may be more beneficial.

It is known that the structural units of B

2

O

3

oxide have a rela-

tively larger phonon energy (1400 cm

1

) [17] than that of TeO

2

counterpart (750 cm

1

), which is more suitable to bridge the

energy difference between the Er

3+

:

4

I

11/2

?

4

I

13/2

transition and

the Ce

3+

:

2

F

5/2

?

2

F

7/2

transition. Meanwhile, B

2

O

3

oxide is a good

glass former, and adding B

2

O

3

oxide into glass host can enhance

its thermal stability and in turn improve the resistance for crystal-

lization [18]. In this paper, Ce

3+

ions and B

2

O

3

oxide were intro-

duced into the Er

3+

single-doped tellurite glass with composition

TeO

2

–GeO

2

–Li

2

O–Nb

2

O

5

to improve the 1.53

l

m fluorescence

emission of Er

3+

, with the aim to make full use of the ET from

Er

3+

:

4

I

11/2

level to Ce

3+

:

2

F

7/2

level meanwhile to provide a suitable

phonon energy for this ET process. The absorption spectra, fluores-

cence spectra, up-conversion emissions, Raman spectra and DSC

curves were measured to evaluate the effects of Ce

3+

ions and

B

2

O

3

oxide introductions on the 1.53

l

m band fluorescence emis-

sion, structural nature and thermal stability of glass hosts.

Meanwhile, the relevant microscopic parameters characterizing

ET between Er

3+

and Ce

3+

ions were calculated, and the 1.53

l

m

band signal gain of Er

3+

/Ce

3+

co-doped tellurite glass fiber with

B

2

O

3

oxide was studied theoretically to reveal its feasibility as a

gain medium for high gain EDFA and laser.

2. Experimental procedures

2.1. Glass preparation

The Er

3+

/Ce

3+

co-doped tellurite glasses were prepared using

conventional melt-quenching technique with molar compositions

(73 x)TeO

2

–15GeO

2

–5Li

2

O–5Nb

2

O

5

–1Er

2

O

3

–1Ce

2

O

3

–xB

2

O

3

(x =0,

3, 6 mol%), and they were labeled as TGB0, TGB1 and TGB2 corre-

sponding to B

2

O

3

amount for clarity, in which Li

2

O, B

2

O

3

compo-

nents and Er

3+

,Ce

3+

ions were introduced in Li

2

CO

3

,H

3

BO

3

,Er

2

O

3

and Ce

2

O

3

compounds, respectively. The starting materials TeO

2

,

GeO

2

,Li

2

CO

3

,Nb

2

O

5

and H

3

BO

3

were reagent-grade, Er

2

O

3

and

Ce

2

O

3

were high purity (99.99%). Batches of 10 g powders were

weighed and mixed thoroughly in a high purity crucible and

melted at temperature of about 900 °C for 0.5 h in the dry gas

atmosphere. The obtained high-temperature glass melt was casted

immediately into a preheated stainless steel mold and then

annealed at 10 °C below the glass transition temperature for 2 h

and finally cooled down to the room temperature slowly. All the

glass samples were cut and polished into the same size of

10 10 2mm

3

to meet the requirements for further spectro-

scopic measurements. The Er

3+

single-doped glass sample

(74TeO

2

–15GeO

2

–5Li

2

O–5Nb

2

O

5

–1Er

2

O

3

) was also prepared as a

reference and denoted as TGE.

2.2. Sample measurements

The glass sample density was measured based on the

Archimede principle using distilled water as an immersion liquid.

The refractive index was measured based on the minimum devia-

tion method using a prism coupler (SPA-4000) with error of 0.001.

The doped RE concentration was calculated from the measured

sample density and initial composition, and the obtained results

were listed in Table 1. The UV–Vis–NIR absorption spectrum of

glass sample was recorded using a Perkin–Elmer–Lambda 950

spectrophotometer with resolution of 1 nm, and the mid-infrared

absorption spectrum was measured using a Thermo-

Nicolet-Nexus 470 FT-IR spectrophotometer with resolution of

1cm

1

. The fluorescence emission spectrum was measured using

a Jobin Yvon Triax 550 spectrophotometer with resolution of

1 nm upon excitation of a 975 nm LD. The Raman spectrum was

measured using a confocal Horbia–Jobin–Yvon HR800 spectrome-

ter with resolution of 0.65 cm

1

upon excitation of a 488 nm

Argon ions laser. The thermal stability of glass sample was deter-

mined using a differential scanning calorimeter (DSC) of TA

Instrument Q2000 with precision of 0.1 °C at a heating rate of

10 K/min from room temperature to 600 °C. The above measure-

ments were performed at room temperature.

3. Results and discussions

3.1. Thermal stability

The glass fiber drawing is a reheating process, and any crystal-

lization during this process will increase the optical scattering loss,

which will affect the signal transmission characteristics. Therefore,

the thermal stability is very important for glass sample and relates

its subsequent practical applications. The thermal stability is gen-

erally characterized by three temperature parameters [19]: the

0

5

10

15

20

25

2200 cm

-1

1530 nm

980 nm

4

F

5/2

ESA

2

F

7/2

Ce

3+

4

F

7/2

2

H

11/2

4

S

3/2

4

I

9/2

4

I

11/2

4

I

13/2

Energy

(10

3

cm

-1

)

Er

3+

4

F

9/2

4

I

15/2

2

F

5/2

ET

3600 cm

-1

ΔE

N

1

N

3

N

2

R

13

R

31

Upconversion

C

UP

W

32

A

21

R

12

R

21

Fig. 1. The energy level diagram of Er

3+

,Ce

3+

ions and relevant transitions pumped

at 980 nm.

Table 1

Density

q

, refractive index n, concentration N

Er

of Er

3+

, concentration N

Ce

of Ce

3+

, glass

transition temperature T

g

, onset crystallization temperature T

x

, the difference DT

(=T

x

T

g

), fluorescence lifetime s

m

, spontaneous radiative transition probability A

rad

;

radiative lifetime

s

rad

and branching radio b in TGE and TGBx (x = 0,1,2) glass samples.

Glass hosts TGE TGB0 TGB1 TGB2

q

(g/cm

3

) 4.930 4.950 4.806 4.689

n (±0.001) 2.010 2.019 2.024 2.030

N

Er

(10

20

/cm

3

) 3.806 3.782 3.712 3.666

N

Ce

(10

20

/cm

3

) 0 3.782 3.712 3.666

T

g

(±0.5 °C) 397.8 398.4 399.0 401.3

T

x

(±0.5 °C) 549.2 552.1 555.1 559.7

D

T =T

x

T

g

(±0.5 °C) 151.4 153.7 156.1 158.4

4

I

13/2

?

4

I

15/2

s

m

(ms) 3.25 3.09 2.98 2.81

4

I

13/2

?

4

I

15/2

A

rad

(s

1

) 297.73 313.82 325.81 336.10

s

rad

(ms) 3.36 3.19 3.07 2.98

4

I

11/2

?

4

I

13/2

A

rad

(s

1

) 57.50 57.26 53.74 53.69

4

I

11/2

?

4

I

15/2

A

rad

(s

1

) 280.75 279.57 282.15 281.88

4

I

11/2

?

4

I

13/2

+

4

I

15/2

A

rad

(s

1

) 338.25 336.83 335.89 335.57

s

rad

(ms) 2.96 2.97 2.98 2.98

4

I

13/2

?

4

I

15/2

b 1111

4

I

11/2

?

4

I

15/2

b 0.83 0.83 0.84 0.84

4

I

11/2

?

4

I

13/2

b 0.17 0.17 0.16 0.16

150 F. Yang et al. / Optical Materials 47 (2015) 149–156

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功