Contents lists available at ScienceDirect

Optics Communications

journal homepage: www.elsevier.com/locate/optcom

Weak scratch detection and defect classification methods for a large-

aperture optical element

Xian Tao, De Xu, Zheng-Tao Zhang

⁎

, Feng Zhang, Xi-Long Liu, Da-Peng Zhang

Research Center of Precision Sensing and Control, Institute of Automation, Chinese Academy of Sciences, Beijing, China

ARTICLE INFO

Keywords:

Optical inspection

Weak scratches

Surface defects classification

Large-aperture optical element

ABSTRACT

Surface defects on optics cause optic failure and heavy loss to the optical system. Therefore, surface defects on

optics must be carefully inspected. This paper proposes a coarse-to-fine detection strategy of weak scratches in

complicated dark-field images. First, all possible scratches are detected based on bionic vision. Then, each

possible scratch is precisely positioned and connected to a complete scratch by the LSD and a priori knowledge.

Finally, multiple scratches with various types can be detected in dark-field images. To classify defects and

pollutants, a classification method based on GIST features is proposed. This paper uses many real dark-field

images as experimental images. The results show that this method can detect multiple types of weak scratches in

complex images and that the defects can be correctly distinguished with interference. This method satisfies the

real-time and accurate detection requirements of surface defects.

1. Introduction

Large-aperture optics are indispensable in inertial confinement

fusion (ICF) high-power laser systems, such as National Ignition

Facility (NIF) [1] in the United States and Laser MegaJoule (LMJ)

Facility [2] in France, and have the dual function of guiding and

amplifying laser beams. The surface defects of large-aperture optics,

such as scratches, digs, and bubbles, may harm the safe operation of

high-power laser system. Therefore, detecting surface defects has an

important practical significance. Currently, automated visual inspec-

tion based on the dark-field scattering principle should be a rapid and

effective method to detect defects of large-aperture optical elements.

There are a number of methods to detect surface defects. The French

ICF project LMJ uses a high-resolution 45-Mpixel CCD camera with an

LED array edge-illuminating frame [3] to detect defects [4]. proposes a

defect detection method using dark-field back illumination and a

camera to obtain the flaw information for full sized optics at one time,

but the accuracy of these two methods is at most 110 µm [5,6]. design a

surface defect evaluation system (SDES) with an area CCD and a

precise two-dimensional motion platform. The detection diameter of

the SDES is up to 810×460 mm

2

with a resolution of 0.5 µm, but the

image acquisition time in sub-aperture scanning is longer than half an

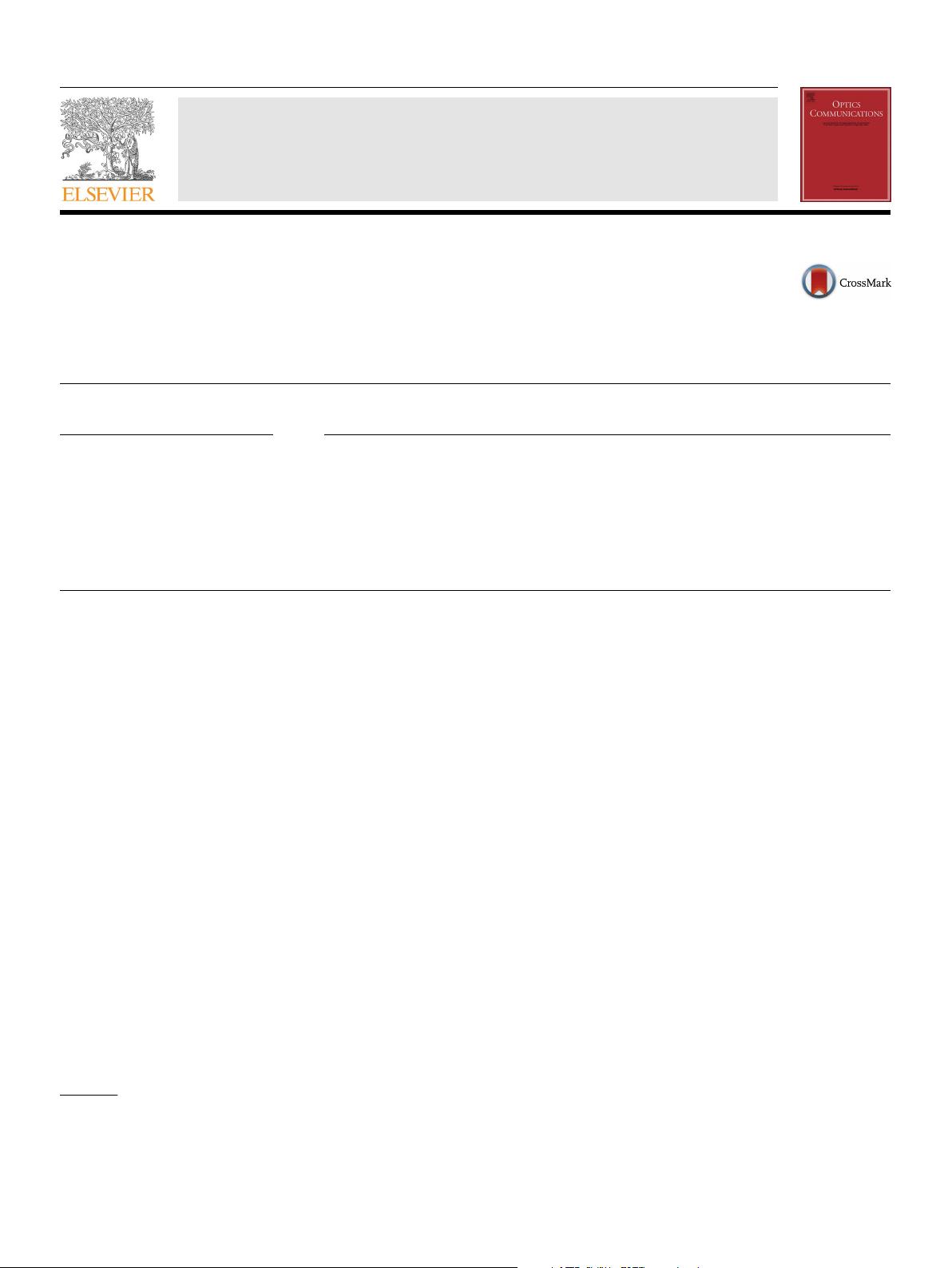

hour. To achieve fast and high-precision detection of large-aperture

optical elements, a new and effective inspection instrument [7,8] with

two imaging systems for large-aperture optical elements was proposed.

It combines a dark-field imaging system (DFIS) with a line-scan

camera at a 10 µm resolution and a bright-field imaging system

(BFIS) with a microscopic camera at a 0.85 µm resolution. The DFIS

is developed to scan the entire optical element to quickly obtain all of

the distributions of surface flaws for coarse detection. BFIS is used to

measure the size of the flaws and recognize the flaw type for fine

detection.

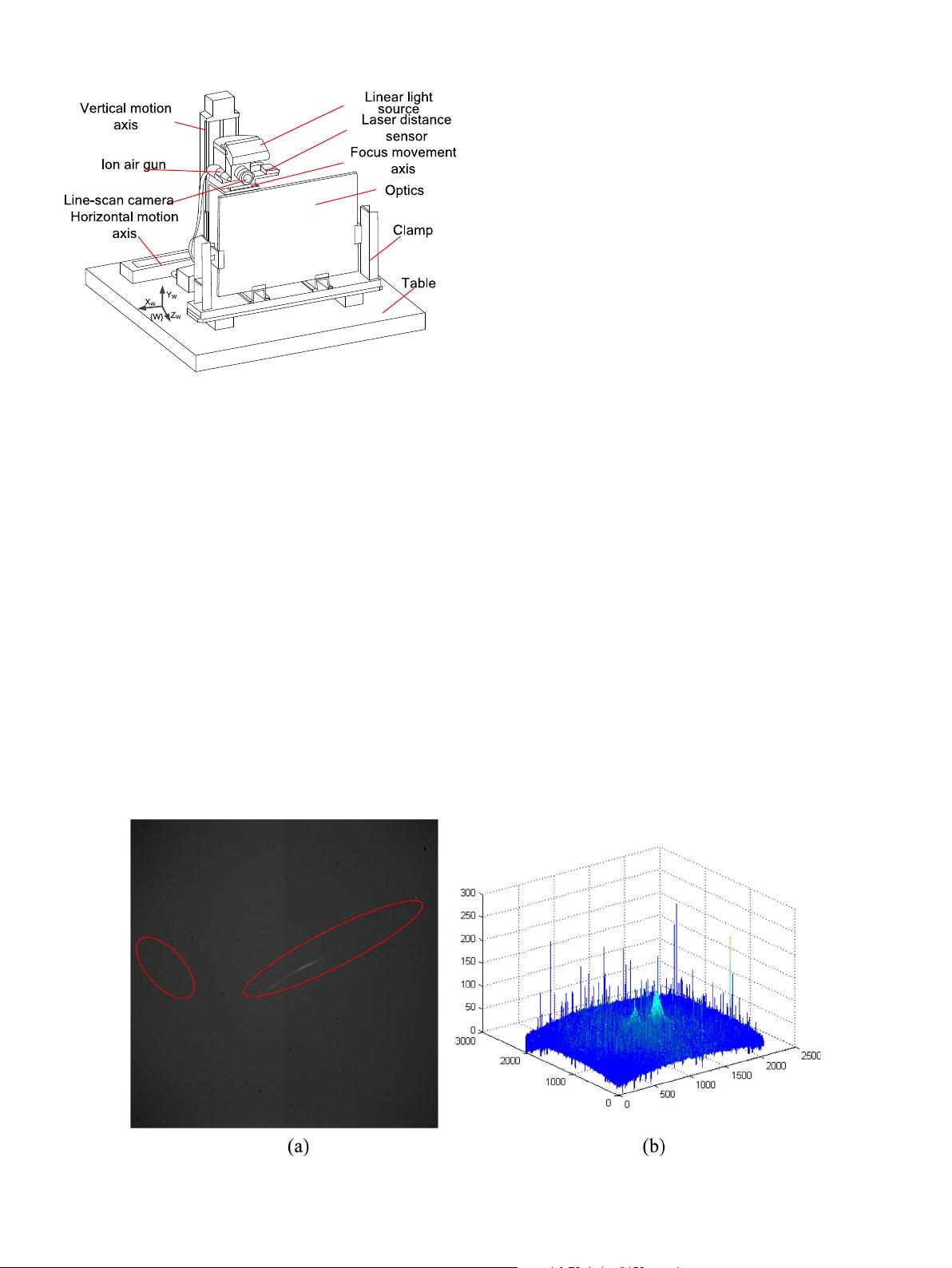

The original system works well, but defect detection encounters

problems in some special conditions. On the one hand, scratches on the

optics, such as Nd-doped glass, are usually shallow. In [9] Fig. 1, the

depth of the scratch after burnishing is only approximately 200–

300 nm, as obtained by an interference microscope. The detected

scratches in our previous paper [8] are deep and obvious and can be

effectively detected by conventional binarization methods. In some

related works [10–12], the detected flaws are also often notably deep or

have a large area. However, these detection methods can lead to partial

detection and lead to undetectable problems when they encounter

these weak scratches. Meanwhile, there are surface defects in the

optical element compared to pollutants, such as dust, fibres, dirt, bright

spot, fingerprint, and so on. These disturbances are inevitably involved

in the inspection and can affect the detection results [13]. realizes

automated discrimination between digs and dust particles on optical

surfaces using dark-field scattering microscopy. In [14], the machine

learning method is applied to classify linear defects and circular flaws.

In current detection systems, such as those described in [7,8], these

disturbances are removed by manual marking before defect detection

begins. This method significantly reduces the detection efficiency. To

http://dx.doi.org/10.1016/j.optcom.2016.10.062

Received 11 July 2016; Received in revised form 26 October 2016; Accepted 28 October 2016

⁎

Corresponding author.

E-mail address: zhengtao.zhang@ia.ac.cn (Z.-T. Zhang).

Optics Communications 387 (2017) 390–400

Available online 10 November 2016

0030-4018/ © 2016 Elsevier B.V. All rights reserved.

MARK

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功