all these investigations were on phosphorus-doped silicon.

Little attention was paid to how the carbon or oxygen in

organic carriers interact with boron dopants in silicon and

whether electrically active defects exist in boron-doped silicon

via SAMM.

In this work, we investigated boron-doped silicon by SAMM

from the aspects of activation rate and defects. Allylboronic

acid pinacol ester (ABAPE) molecules were applied to

introduce boron dopants into silicon by SAMM doping. The

hole and boron dopant concentrations were measured by Hall

effect measurement and secondary ion mass spectrometry

(SIMS), respectively. To fully understand the defects in

SAMM-doped silicon, we employed deep leve l transient

spectroscopy (DLTS) and minority carrier transient spectros-

copy (MCTS) to investigate the majority and minority carrier

trap states, respectively. The results show that carbon

impurities do not bind with boron dopants. Carbon impurities

only form minority carrier trap states that have no impact on

the ionization rate of boron dopants, as a result of which boron

dopants are close to full activation. Only oxygen impurities will

bond with boron dopants, resulting in the deactivation of less

than 1% boron dopants.

■

RESULTS AND DISCUSSIONS

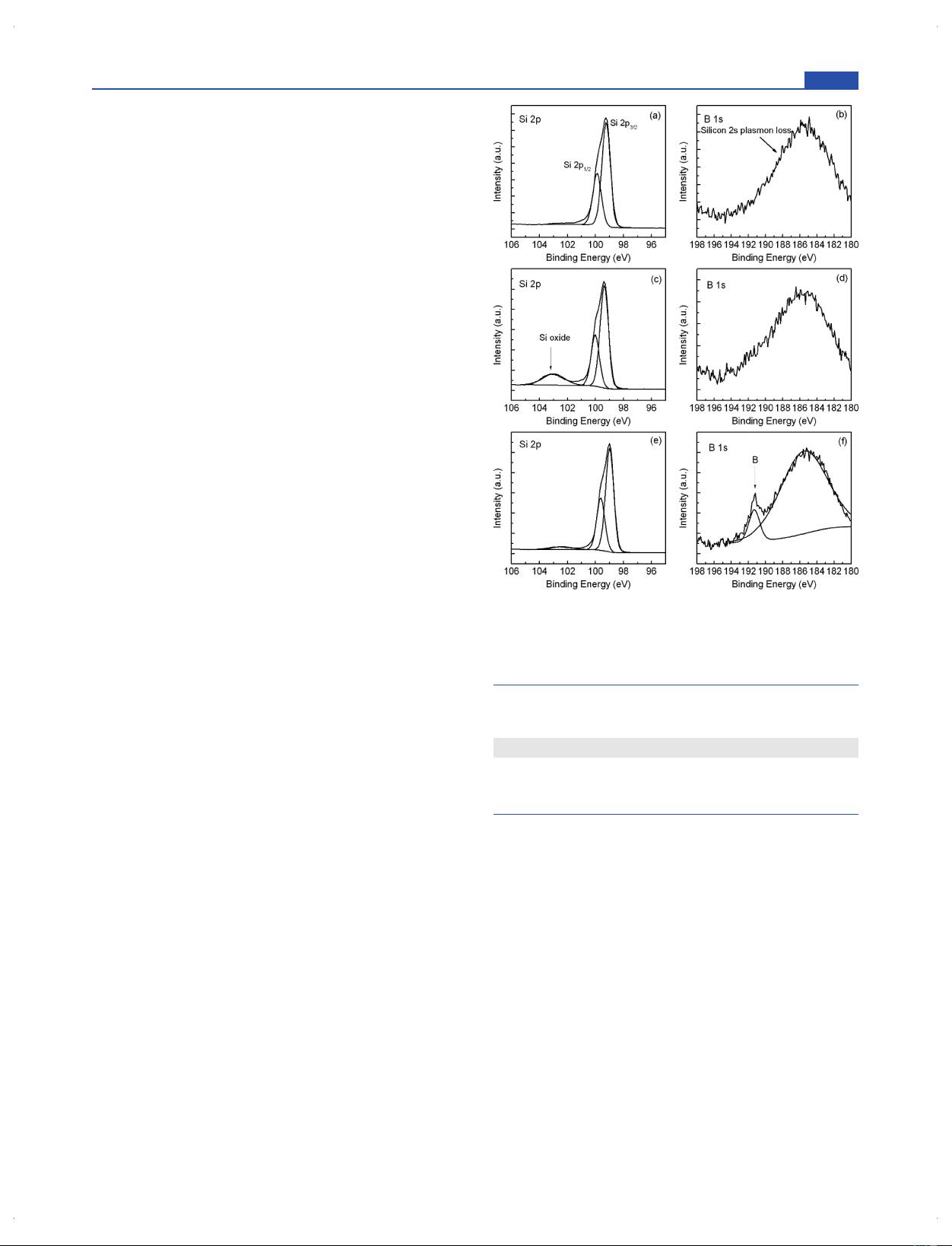

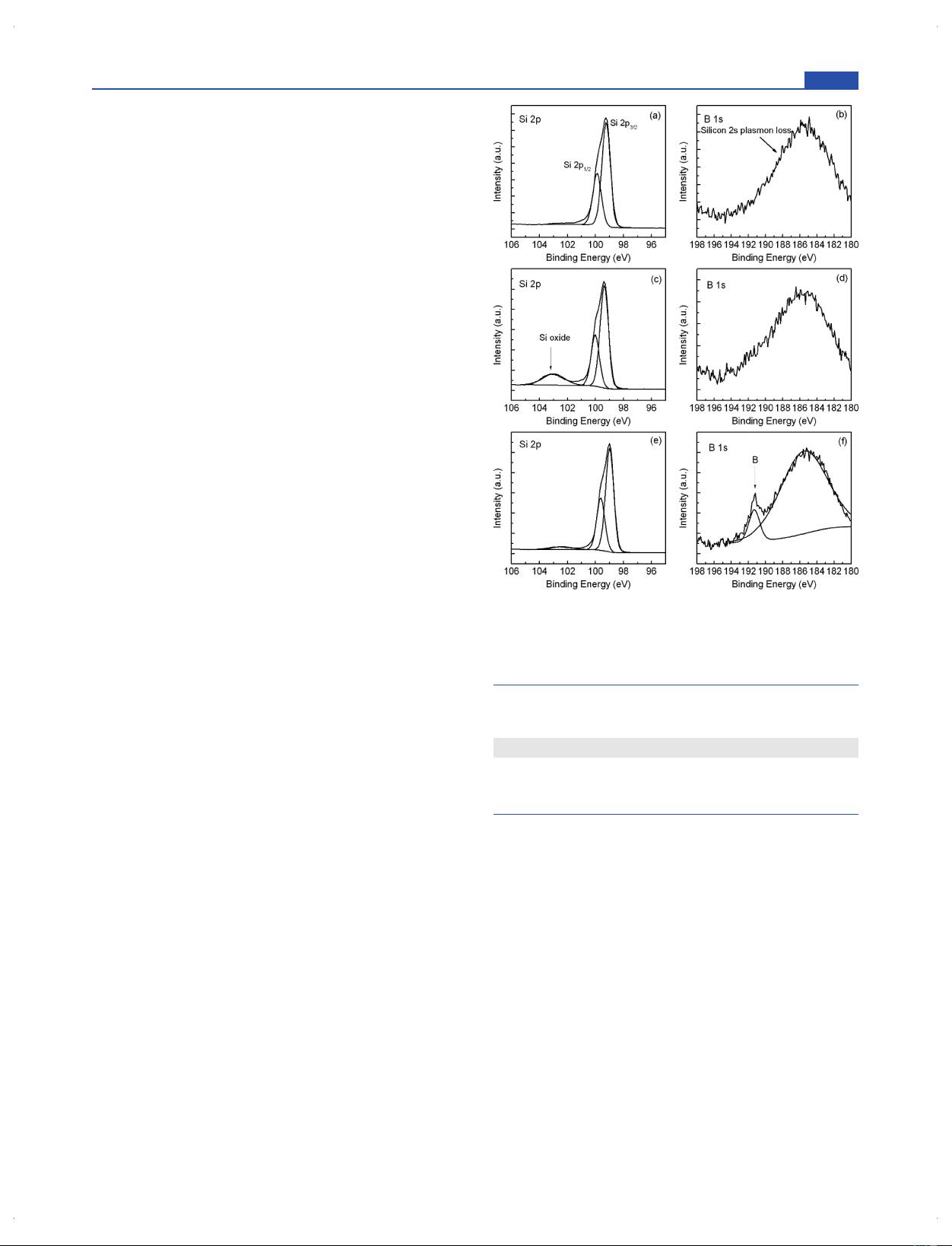

ABAPE monolayers were covalently bonded onto a silicon

surface following the process described in refs 1 and 15.A

compact and robust molecular monolayer was demonstrated

by co mparing X-ray photoelectron spectroscopic (XPS)

spectra of blank sample (freshly HF-etched Si), control sample

(ABAPE/p-xylene = 0:1), and ABAPE-functionalized sample

(ABAPE/p-xylene = 1:2), as shown in Figure 1 and

Supplementary Figures S2,S3.InFigure 1a, the silicon dioxide

peak (102.9 eV) is nearly invisible on the freshly HF-etched

silicon surface, and a Si 2p peak at 99.5 eV due to the Si

substrate splits into Si 2p (3/2) at 99.2 eV and Si 2p (1/2) at

99.8 eV. After heat treatment in p-xylene, the silicon dioxide

peak at 102.9 eV (fwhm 1.8 eV) shows up on the control

sample due to surface oxidation (Figure 1c). However, with a

compact ABAPE monolayer covering the silicon surface, only a

tiny silicon dioxide peak was detectable on the B-function-

alized silicon surface (Figure 1e), indicating that a compact

and robust monolayer of ABAPE has been successfully grafted.

No B 1s was detected on blank sample (Figure 1b) and control

sample (Figure 1d), but a broad peak of Si 2s plasma loss was

detected. In contrast, after functionalization with ABAPE, a

peak at 191.3 eV (fwhm 1.5 eV) was present in Figure 1f,

which is ascribed to the boron in the ABAPE monolayer. In

addition, C 1s narrow scans also support the successful

coupling of boron-containing molecules, as shown in

Supplementary Figure S3.

To evaluate the boron doping process, SAMM doping was

first performed on a high-resistivity silicon wafer (>10 kΩ cm).

Experiment details can be found in our previous publication.

15

A control sample was prepared by removing ABAPE in p-

xylene solvent. van der Pauw four-probe measurements were

applied in darkness to measure the sheet resistance. Table 1

compares the experiment results of blank sample (bare silicon

wafer), control sample, and B-doped sample. The sheet

resistance of the control sample (299.60 kΩ/□) is very

close to that of blank sample (315.82 kΩ/□), which indicates

that SAMM doping introduces negligible contamination. After

boron was doped into silicon via SAMM, the sheet resistance

dramatically decreased to 3.20 kΩ/□. This drop in sheet

resistance is exclusively attributed to molecular monolayer

doping, and hence, effective boron doping in silicon has been

demonstrated.

As we have discovered that carbon contamination from the

organic dopant carriers can deactivate as least 20% of the

phosphorus dopants in phosphorus-doped silicon by SAMM,

15

the investigations on the activation rate and defects in boron-

doped silicon became the keynote of this research. First, the

boron distribution near the silicon surface was analyzed by

SIMS. As shown in Figure 2a, the boron concentration rapidly

drops from 1.59 × 10

19

at the surface to 2.6 × 10

18

cm

−3

at ∼5

nm below the surface. The boron dopants then drop to 6.1 ×

10

15

cm

−3

at ∼104 nm below the surface. Because a monolayer

of ABAPE is grafted on the silicon surface, the total amount of

initial dopants is limited. The SIMS data from 5 to 104 nm

agrees well with the limited-source diffusion. By fitting the

limited-source diffusion model into SIMS data,

9

adiffusivity of

7.24 × 10

−15

cm

2

s

−1

was obtained, comparable to the

diffusivities for boron reported in the literature.

21

The sharp

decrease at the first 5 nm was likely related with the observed

Figure 1. XPS narrow scans of blank sample, control sample, and

ABAPE-functionalized sample. (a) and (b) are Si 2p and B 1s narrow

scans on blank sample. (c) and (d) are Si 2p and B 1s narrow scans on

control sample. (e) and (f) are Si 2p and B 1s narrow scans on

ABAPE-functionalized sample. The takeoff angle is 45°.

Table 1. Sheet Resistance of Blank Sample, Control Sample,

and Boron-Doped Samples by van der Pauw Technique

sheet resistance (kΩ/□)

blank sample 315.82

control sample 299.60

boron-doped sample 3.20

ACS Applied Electronic Materials Article

DOI: 10.1021/acsaelm.9b00748

ACS Appl. Electron. Mater. XXXX, XXX, XXX−XXX

B

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功