RGO涂层弹性纤维作为可穿戴应变传感器,可全面检测人体运动

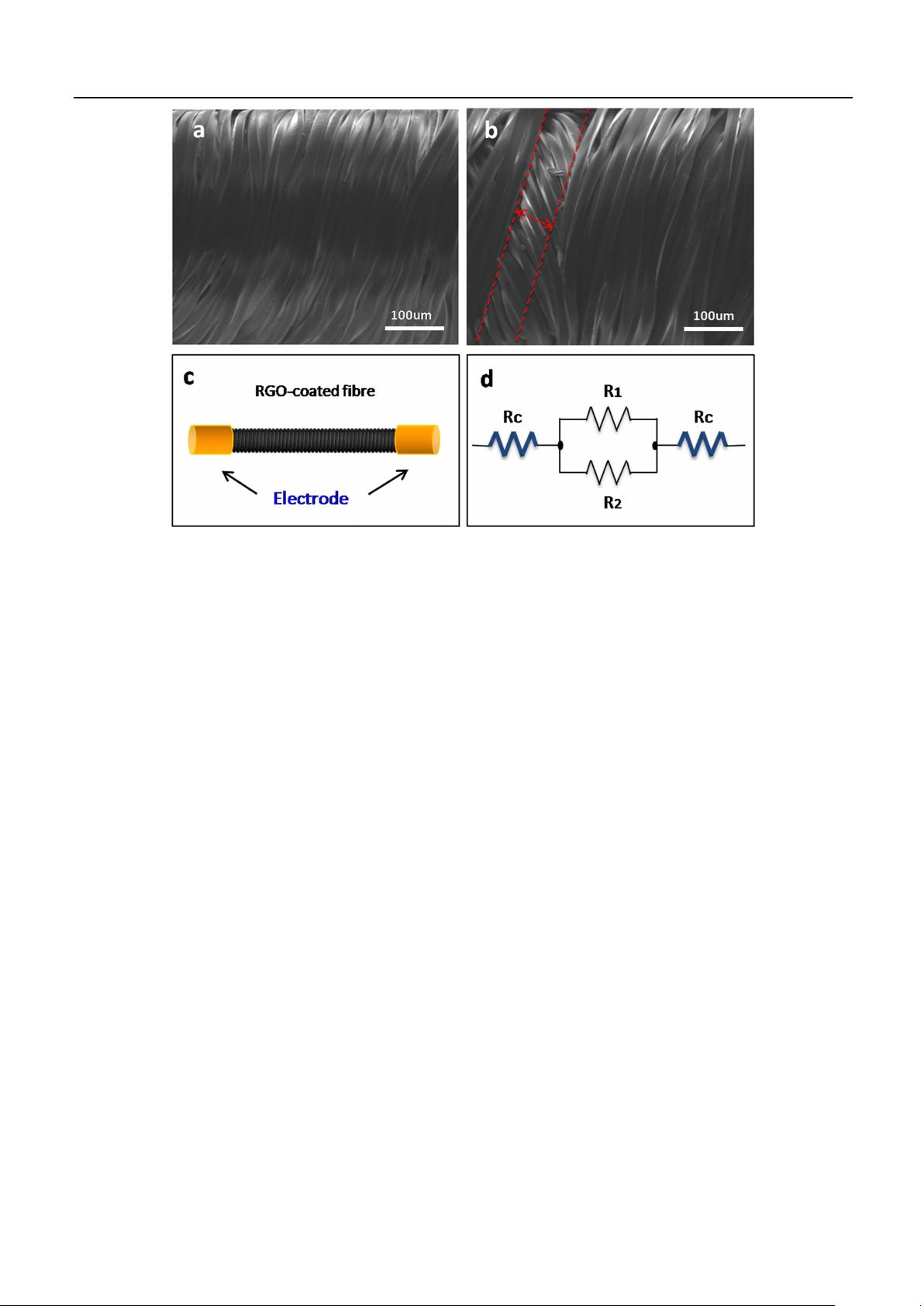

在当前的科技发展背景下,智能可穿戴设备作为市场新宠,正逐渐渗透到日常生活的方方面面。本文研究的内容是利用具有高弹性的纤维作为功能性载体,通过等离子体处理、浸涂以及水热还原等步骤简单地在其上涂覆还原氧化石墨烯(rGO),最终制作成可穿戴的应变传感器。这一研究的成果,即RGO涂层弹性纤维,能够在全范围内检测人体运动,包括关节弯曲和脉搏跳动等。而且,这些传感器还具备高灵敏度、良好的稳定性和出色的重复性。 可穿戴技术的发展,尤其是与健康监测相关的产品,已经成为一个热点。随着老年人口和超重人群对自我健康监测需求的增加,以及运动员对于运动强度监测、体态和健身训练的追求,人们期望通过智能服装等可穿戴监测设备过上更高质量和更高效的生活。 智能服装通过衣服和纺织品间接接触人体约90%的皮肤表面,显示出了显著的优势,即可以长时间连续收集人体各种身体部位的运动数据。另外,智能服装还可以与无线传感器配合使用,提供更加灵活和便捷的人机交互方式,进一步推动了智能服装在日常生活中应用的广泛性。 文章中提到的感应器采用的弹性纤维载体,通过特殊的工艺处理,使其具备了作为应变传感器的基本特性。等离子体处理是一种利用等离子体状态下的高能粒子轰击材料表面,以此改变材料的表面特性,提高材料表面的附着性能。浸涂是一种将基材浸入特定溶液中,让溶液中的物质沉积到材料表面的过程。水热还原则是一种在密闭容器中,在水溶液环境下的热化学反应,常用于还原氧化物制备单质或低价态物质。 研究中的rGO涂层弹性纤维传感器之所以能实现全范围人体运动检测,是因为rGO本身具有非常好的导电性和机械柔性。在材料被拉伸时,rGO涂层会相应产生变化,通过测量这些变化,可以对材料的应变进行检测。而高灵敏度、稳定性以及重复性,使得该传感器在实际应用中具有很大的潜力。 这项研究还特别强调了该传感器的经济性,即其制作过程简单,成本低廉。这对于智能服装、智能纺织品、健康护理和娱乐领域的实际应用具有非常重要的意义。由于其低成本的特性,可以预见到这种传感器在市场上的大规模应用将会推动整个智能可穿戴设备行业的成本下降,从而进一步促进其在普通消费者中的普及。 在补充材料中,我们也可以看到该研究团队提供了详细的实验数据和分析,这些信息有助于其他研究者或工程师理解和验证该传感器的性能,以及如何进行进一步的优化和应用开发。RGO涂层弹性纤维作为可穿戴应变传感器,不仅在技术上取得了突破,而且在商业应用方面也展现出了巨大的潜力。

剩余7页未读,继续阅读

- 粉丝: 11

- 资源: 953

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- simulink 三机九节点系统风电调频,mppt运行下附有下垂控制和惯性控制,风电渗透率20%,带参考文献

- 西门子smart200plc与4台台达变频器modbus通讯 1,读写变频器的内部参数 2,控制变频器启停,读频率电流 3,设置变频器输出频率 4,有彩色接线图,和参数设置说明, 昆仑通泰触摸程序 有

- MATLAB环境下EMG信号降噪(去除心脏干扰)方法 算法运行环境为MAT;AB R2018a,执行MATLAB环境下EMG信号降噪(去除心脏干扰),采用概率自适应模板减法PATS,经验模态分解方法E

- 条形码检测 avt相机 halcon联合C++联合C#读条码源码 AVT的CCD相机飞拿采集图片,流水线上面运行,传感器感应条形码,相机采图,识别二维码,当读取二维码不联系后,开始通过串口控制输出点停

- 基于Windows.RTX64实时系统的仿真系统框架,用于分析工作时序(ns级),系统动态分析,集采集、分析、处理等于一体的多功能系统 可搭载光纤卡,图像卡,高速A D等板卡

- Simulink集成外部C语言实现PID功能,与Simulink自带pid模块功能一致 可直接进行DSP28335等的代码生成,拖过来直接用,加快开发进度 下图三显示这6种方式达到了基本一致的效果

- 分布式驱动电动汽车LQR DYC 直接横摆力矩控制 最优 规则扭矩分配控制pid计算纵向扭矩需求, 上层lqr计算 下层最小附着利用率分配 扭矩分配 效果优良 稳定性控制 操纵稳定性 matlab

- 四轮独立驱动电动汽车的车辆状态估计,分别采用无迹卡尔曼,容积卡尔曼,高阶容积卡尔曼观测器等,可估计包括纵向速度,质心侧偏角,横摆角速度,以及四个车轮角速度七个状态 模型中第一个模块是四轮驱动电机用f

- 开发板STM32 三轴联动 带插补 加减速 源代码 MDK 源码 分别基于STM32F1和STM32F4两套的三轴联动插补(直线圆弧两种带)加减速的源码,基于国外写的脱机简易雕刻机源码的项目修改,添加

- 三相电压型PWM整流器+双向buck boost matlab仿真 电压电流双闭环控制 dq变 波形完美 ps:可代做仿真

- 基于固定400Hz正弦信号注入的在线搜索永磁同步电机MTPA自动追踪运行的仿真,考虑了电感的饱和以及电机参数的变化,不需要电机的具体参数便可以自动寻求到最佳MTPA工作点,模型采用离散化的方式运行,与

- 基恩士KV7500 程序 ~ 基恩士KV7500系列程序,KV7500+KV-C64X+KV-C64T等输入输出模块,KV-XH16EC定位控制模块 检测机程序 松下A6系列总线控制伺服电机和总

- IronPython-2.6.2-Src-Net20.zip

- Labview条码追踪系统JKI+ AMC结合的框架,扩展性强,适用于各种项目

- PFC单轴压缩代码,非均质模型,包括声发射,根据裂纹数截图同时输出应力和位移云图数据,拉剪裂纹等

- IronPython-2.6.2-Net20.msi

信息提交成功

信息提交成功