Page 2 of 19

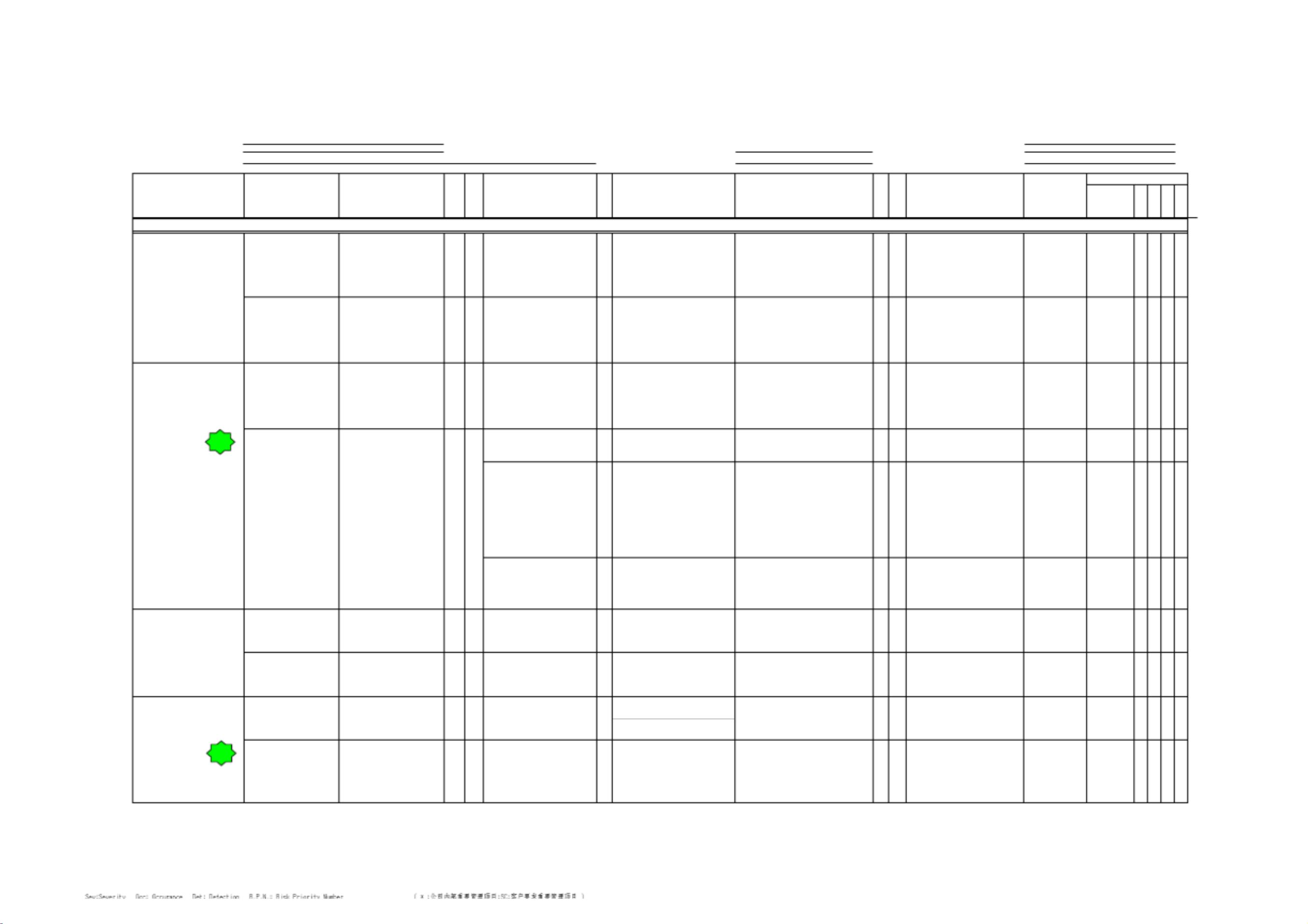

Co.,Ltd. (PROCESS FMEA)

Item Page no. 19

Model Year/Vehicle: Responsibility Prepared by

Core Team Key Date

R Action Results

& Current Control Current Control

P

Recommended S O D R

Process Descpription Potential Potential Potential Prevention Detection

N Action(s) Res.&Tar. e c e P

&Process Purpose Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

C

L

A

S

S

FMEA date

5.Label print print badness difficult to trace 4 operating NG 2 training operator label scan. 2 None

5 1

equipment NG 2 check and maintain equipment daily check 2 None

,

label scan.

CDR MECHA

PCB's surface scrape

function error

8

7

PCB scrape by hardness in

process

2 forbid operator wear ring or

other hardness

1 100% visual check

1 100%

2 next station 100% function check

2 100%

4

3

none

ESD destroy electrical function 7 operator not wearing 2

use ESD cleaner to get rid of ESD

1.daily check before line start 2 None

ESD failured ESD band 1. 4

2.check ESD of operating areas

2.

oversight on inspection

NG parts released to

product line,result in

production function fail as

can't workable or

instability

,

8

7

parts put into next station

without inspection because of

miss operating of operator

,

2 dispart the checked parts and

without check parts

if parts have checked ,will make

a mark on it

100% fuction check

100%

100% visual check on parts using

station

100%

4

3

none

`

NG parts released to 6 1 miss operating 2 qualification training on 4 None

product line 4 1 inspection 3

2 tester failure 2 emendation on equipments emendation list of equipments 3 None

2

100% fuction check

100%

FT

( 2 ,

2

35.3dbuvemf

fuction check

4

36.7dbuvemf

: 2007/06/20

( 2 "TNS"

"on" "OFF"

2 4 1

2 ACC

,

: 2007/06/11

7. fix main PCB to chassis module chassis is NG assembly 7 handling carelessly by 2 None 2 None

&screwing out of shape 4 operator or due to delivery 7

( ST:A-01) IQA

7. check by hisself

&

NG assembly fixing NG 7 pressure not enough 2 use cylinder jig check pressure daily and when 4 None

4 model changed

fixing to wrong location 2 training operator 100% visual double check 4 None

100% 7

screw loose/tighten rattle noise heard when 6 screw driver torque too small 2 use torque meter to control check torque daily and when 4 None

shaking due to loose 4 torque model changed

slide occurred due to 6 screw driver torque too big 2 use torque meter to control check torque daily and when 4 None

tighten 4 torque model changed

stick sheet to wrong can't load CD 7 miss operating 2 1.training operator 100% visual double check 4 None

location 1. 100% 7

2.process sheet

2.

100% fuction check

100%

visual check by warehouseman & IQA

16

16

28

64

56

56

64

56

28

36

16

56

48

48

48

6. inspect main PCB

(ST:PT01)

6. main PCB

overview NG

6

:RF-PT-03,050705

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功