Introduction

www.ti.com

2

SPRA605A–February 2000–Revised August 2017

Submit Documentation Feedback

Copyright © 2000–2017, Texas Instruments Incorporated

TMS320F240 DSP Solution for Obtaining Resolver Angular Position and

Speed

5.3 PGA411-Q1 Software Design ................................................................................... 16

5.4 PGA411-Q1 Troubleshooting Guide ........................................................................... 16

5.5 PGA411-Q1 System Modelling in MATLAB Simulink ........................................................ 17

6 TMS320F240 Results...................................................................................................... 17

6.1 Processor Utilization .............................................................................................. 17

6.2 Angular Accuracy and Transient Response ................................................................... 17

7 Conclusion .................................................................................................................. 19

8 References - make clickable links ....................................................................................... 20

List of Figures

1 Resolver, Simplified Functional Diagram and Corresponding Signals................................................ 3

2 Amplitude Spectrum of the Resolver Signals u

1

, u

2

..................................................................... 4

3 Resolver-to-Digital Conversion Using Undersampling and Inverse Tangent ........................................ 4

4 Block Diagram of the Improved Resolver-to-Digital Converter ........................................................ 5

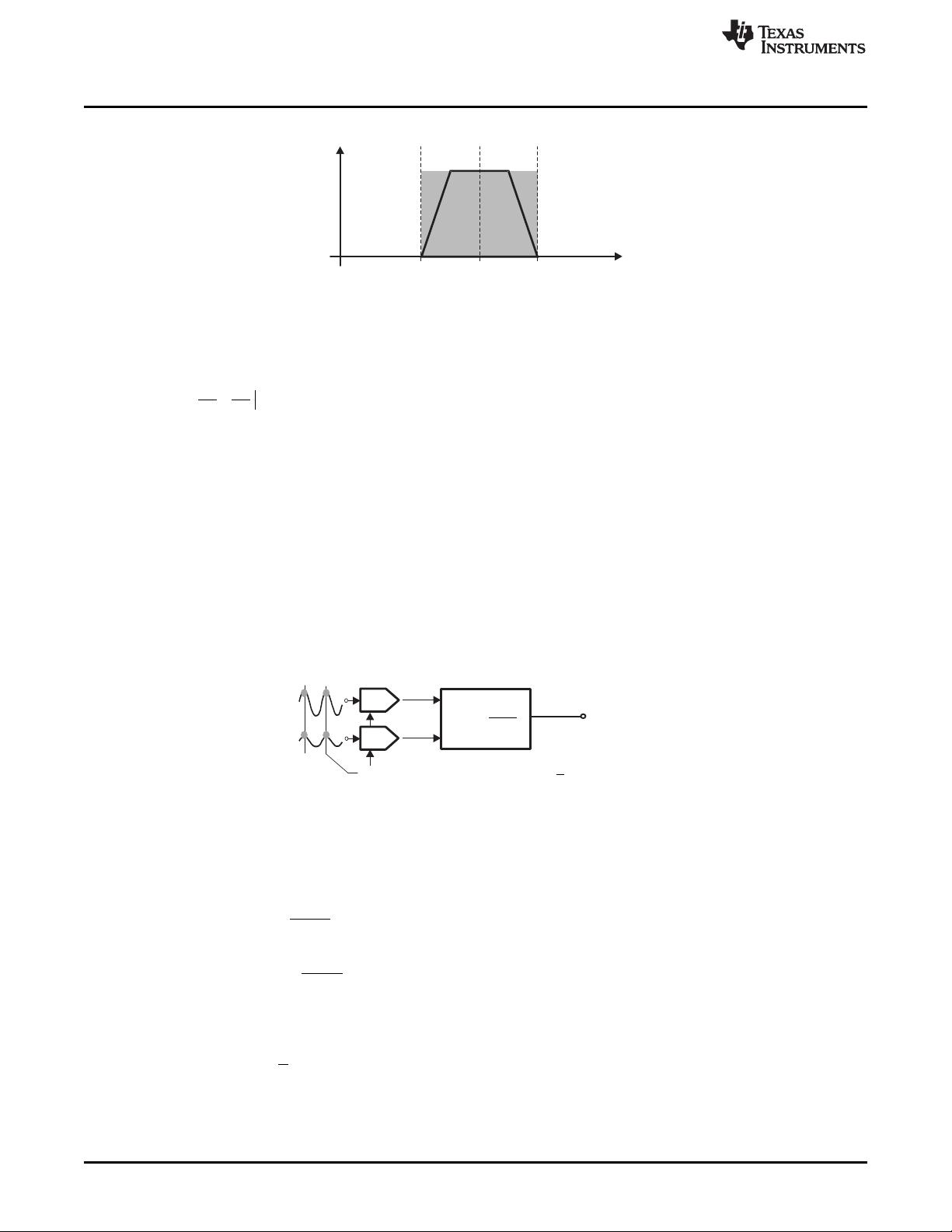

5 FIR Decimation Bandpass Filter Magnitude Response................................................................. 6

6 Angular Error as Function of the Rotational Speed After the FIR Filter .............................................. 7

7 Closed-Loop Position and Speed Interpolator ........................................................................... 7

8 Functional Block Diagram of the TMS320F240 R/D Converter Realization ......................................... 8

9 Signal Conditioning for Resolver to TMS320F240 Interface ........................................................... 9

10 Signal Conditioning for Single-Ended Resolver Signals .............................................................. 10

11 Flowchart of timer3_int .................................................................................................... 12

12 Magnitude Response of the 17-Tap FIR Filter ......................................................................... 14

13 Closed-Loop Angle and Speed Interpolator ............................................................................ 15

14 Normalized Step Response of the Interpolated Angle ................................................................ 15

15 Measured Normalized Step Response for a 1º Angular Step (1º ~ 180) ........................................... 18

16 Resolver Angular Position and Angular Speed ........................................................................ 18

17 Angular Position Error for a Speed Reversal From –180 rpm to +180 rpm ........................................ 19

18 As , but Y-Axis Zoomed ................................................................................................... 19

List of Tables

1 Source Modules and Functional Description ........................................................................... 10

2 Angular Resolution and Bandwidth as Function of KI and KP ....................................................... 16

3 TMS320F240 CPU Loading .............................................................................................. 17

4 TITLE NEEDED ............................................................................................................ 18

Trademarks

All trademarks are the property of their respective owners.

1 Introduction

Digital signal processors are going to become more common in digital motor control applications. They

permit sophisticated real-time control applications to be implemented, which improve dynamic response,

precision, and efficiency. In addition, they enable sensorless control, which reduces total system operating

by eliminating mechanical sensors.

TMS320F240 has been successfully used in sensorless applications. Mechanical sensors, which provide

information on speed or position of the drive, can be eliminated and replaced by high-sophisticated

position and speed estimation algorithms. Typical estimation algorithms include Extended-Kalman-Filters,

INFORM, and Sliding Mode Observers. A further cost reduction can be achieved by the elimination of

phase current sensors by a new algorithm that estimates the actual value of the three phase currents

using only the DC-link current with a shunt resistor. However, there are still applications where sensorless

control cannot achieve the required accuracy and reliability. This is especially true with respect to the

angular position. Examples include servo applications, like robotics and numerically-controlled machine

tools. Mechanical sensors used there are usually incremental encoders and resolvers. Incremental TTL-

encoders provide a pulse train, where each pulse is equivalent to an incremental step. Incremental

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功