没有合适的资源?快使用搜索试试~ 我知道了~

资源推荐

资源详情

资源评论

www.kolmb.com

www.kolmb.com

www.kolmb.com

KOLMB is a professional enterprise

specializing in making Linear

Motion Ball Bearing and related

linear-motion series.

To pursue the higher goal, the

company strictly carry out the

ISO9002:2000 quality system and

has passed the ISO9002 quality

system certification. The company

possess advanced state-of-art

manufacturing equipments, testing

instruments.

。 。 。 。 。 。

。。。。。。。。。。

Moreover, numerous senior

engineers and technicians have

been introduced to develop and

research new products. The

products have been selling to

Japan, U.K., Germany, Italy, Mid-

east area and other countries and

regions.。。。。。。。。。。。。。

BRIEF INTRODUCTION

www.kolmb.com

Basic Dynamic Load Rating (C)

This term is arrived at based on an evaluation of a

number of identical linear systems individually run

in the same conditions, if 90% of them can run with

the load (with a constant value in a constant

direction) for adistance of 50 km without damage

caused by rolling fatigue. This is the basis of the

rating.

Allowable Static Moment (M)

This term defines the allowable limit value of static

moment load,with reference to the amount of

permanent deformation similar to that used for

evaluation of basic rated load (Co).

Static Safety Factor (fs)

This factor is used based on the application

condition as shown in Table 1.

Rating Life of the Linear System

As long as the linear system reciprocates while

being loaded,continuous stress acts on the linear

system to cause flaking on the rolling bobies and

planes because of material fatigue. The travelling

distance of linear system until the fist flaking

occurs is called the life of the systems of the same

dimensions, structure,material,heat treatment and

processing method, when used in the same condi-

tions,This variation is brought about from the essential

variations in the material fatigue itself. The rating life

defined bellow is used as an index for the life expec-

tancy of the linear system.

Rating Life (L)

Rating life is the total travelling distance that 90%

of a group of systems of the same size can reach

without causing any flaking when they operate under

the same conditions.

The rating life can be obtained from the following

equation with the basic dynamic load rating and the

load on the linear system:

L:rating life (km) C:Basic dynamic load rating (N)

P:Load (N)

TECHNICAL INFORMATION

Load Rating

Rating Life

Basic Static Load Rating (Co)

This term defines a static load such that, at the

contacting position where the maximurn stress is

exercised, the sum of the permanent deformation

of the rolling elements and that of the rolling plane is

0.0001 time of the diameter of the rolling elements.

Table 1.Stactic Safety Factors

Condition of use Low limit of fs

When the shaft has less deflection

and shock

1to2

When elastic deformation should

be considered with respect to

pinch load

2to4

When the equipment is subject to

vibration and impacts 3to5

Consideration and influence of vibration impact loads

and distribution of load should be taken into account

when designing a linear motion system . it is difficult

to calculate the actual load . The rating life is also

affected by the operating temperature. In these

conditions, the expression (1) is arranged as follows:

L:Rating life (km) fh:Hardness factor (See Fig.1)

C:Basic dynamic load rating (N)

fT:Temperatuer coefficient (See Fig.2) P:Load (N)

fC:Contact coefficient (See Table 2)

fw:Load coefficient (See Table 3)

The rating life in hours can be calculated by obtaining

the travelling distance per unit time. The rating life in

hours can be obtained from the following expression

when the stroke length and the number of strokes

are constant:

Lh:Rating life in hours (hr)

es:Stroke length (m)

L:Rating life (km)

n1:No.of strofes per minute (cpm)

Lh=

.

For ball type:L=( ) 50

.

For ball type:L=( ) 50

C

p

(1)

3

ff

HH

rr

c

pp

ff

cc

ff

33

ww

ff

.. ..

L

.

10

3

2 s

.

.

n1

60

1

CONTENTS

HRJ

62

PK

60

66

BALL BUSHING COMPARISON LIST

59

COUPLING

TECHNICAL INFORMATION

1

LINEAR BUSH SERIES

9

LM

10

LME

12

LMB

14

LM L

16

LME L

17

LMB L

18

KH

19

LMF/K/H

20

LMEF/K

22

LMBF/K

24

LMF/K/H L

26

LMEF/K L

28

LMBF/K L

30

SC L

42

KBA

47

KBA L

48

KBE

49

56

EK/EF

58

FK/FF

SME L

45

SHAFT SUPPORT SERIES

50

SLIDE UNIT SERIES

39

SC

41

32

LMF/KP

34

LMF/KP L

SME

44

LMHP

33

LMF/KC

36

LMHP L

35

LMEF/KC

37

LMBF/KC

38

40

SC S

43

TBR

46

KBA S

51

S K

52

SA

53

TA

54

SHF

55

BALLSCREW SUPPORT UNIT

57

BK/BFF

61

PKC

64

HOT

63

HRJ-C

65

HOT-C

www.kolmb.com

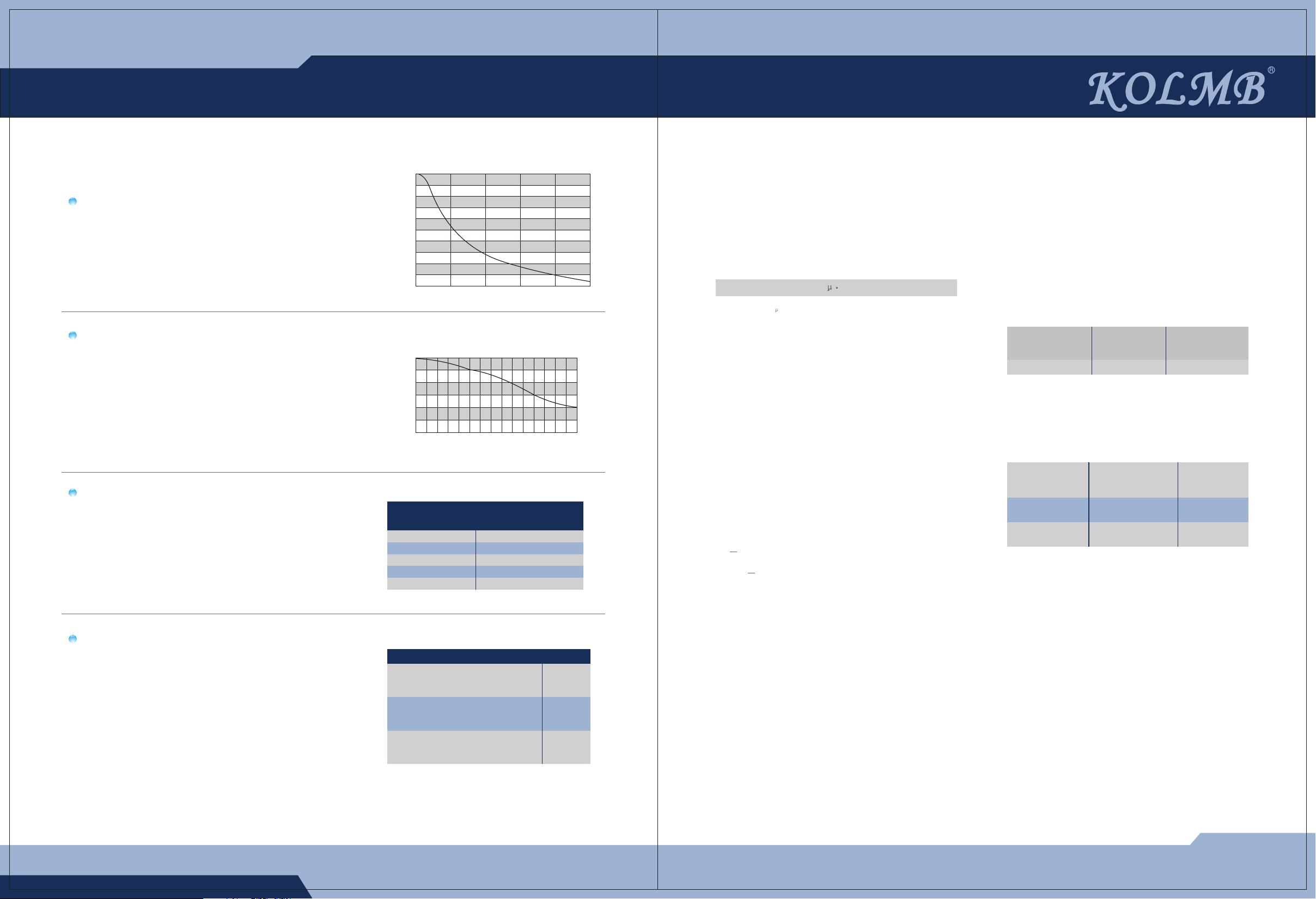

Hardness Factor (fH)

Temperature Coefficient (fT)

Contact Coeffcient (fc)

Load Coefficient (fw)

The shaft must be sufficiently hardened when a linear

bushing is used. lf not properly hardened, permissible

load is lowered and the life of the bushing will be

shortened.

If the temperature of the linear system exceeds 100℃,

hardness of the linear system and the shaft lowers to

decrease the permissible load compared to that of the

linear system used at room temperature. As a result,

the abnormal temperature rise shortens the rating life.

Generally two or more linear bushings are used on

one shaft. Thus, the load on each linear sysem differs

depending on each processing accuracy. Because the

linear bushings are not loaded equally, the number

of linear bushings per shaft changes the permissible

load of the system.

When calculating the load on the linear system, it is

necessary to accurately obtain object weight, inertial

force based on motion speed, moment load, and each

transition as time passes. However, it is difficult to

calculate those valuse accurately because reciprocating

motion involves the repetition of start and stop as well

as vibration and impact. A more practical approach is

to obtain the load coefficient by taking the actual

operatingconditions into account.

Fig.1 Hardness Factor

Fig.1 Hardness Factor

102030405060

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Raceway Hardness HRC

Hardness Factor f

1.0

0.9

0.8

0.7

0.6

0.5

250100 150 200

Temperature of Linear System

Temperature Coefficient f

Table 2 Contact Coefficient

Number of linear

systems per shaft

Contact coefficient fc

1

2

3

4

5

Table 3 Load Coefficient

1.00

0.81

0.72

0.66

0.61

Opearating Conditions

fw

Operation at low speed(15 m/min.

Or less) without impulsive shock

from outside

Operation at intermediate speed

(60 m/min. Or less) without

impulsive shock

Operation at high speed

(over 60 m/min.) With

impulsive shock from outside

1.0 to 1.5

1.5 to 2.0

2.0 to 3.5

The static frictional resistance of the KOLMB

linear system is so low as to be only slightly

different from the kinetic frictional resistance,

enabling smooth linear movement from low to

high speeds. in general, the frictional resistance

is expressed by the following equation.

The frictional resistance of each KOLMB linear

system depends on the model, load weight,

speed, and lubricant. The sealing resistance

depends on the lip interference and lubricant,

regardless of the load.

The ambient working temperature range for each

KOLMB linear system depends on the model.

Consult KOLMB on use outide the recommended

temperature range.

Temperature conversion equation

C=

F=

Using KOLMB linear systems without lubrication increases

the abrasion of the rolling elements, shortening the life

span, The KOLMB linear systems therefore require appro-

priate lubrication. For lubrication KOLMB recommends

turbine oil conforming to ISO Standards G32 to G68 or

lithium base soap grease NO.2. Some KOLMB linear

systems are sealed to biock dust out and seal lubricant in.

If used in a harsh or corrosive environment, however,

apply a protective cover to the part involving linear motion.

Frictional Resistance

F:Frictional resistance :Coefficient of friction

W:Load weight f:Sealing resistance

Ambient

Working Temperature

Lubrication and

Dust Prevention

weight. The sealing resistance of one linear system

is about 2000 to 500 gf. The coefficient of friction

depends on the load weight. Moment load. And pre-

load.Table 6 shows the coefficient of kinetic friction

of each type of linear system which has been installed

and lubricated properly and applied with normalload

(P/C=0.2)

Table 5 Coefficient of Linear System Friction (u)

Table 6 Ambient Working Temperature

Linear Bushing

LMLME LMB -20to80℃

Linear Bushing

LM-ALME-ALMB-A -20to110℃

Linear System

Type

Models

Coefficient of

Friction (u)

Linear Bushing

LMLME LMB 0.002 to 0.003

Linear System

Type

Models

Ambient

Working

Temperature

5

9

5

9

F= W+f

(F-32)

32+ C

3

2

5

4

www.kolmb.com

The KOLMB linear bushing consists of an outer cylinder,

ball retainer, balls and two end rings. The ball retainer

which holds the balls in the recirculating tuucks in held

inside the outer cylinder by end rings.

Those parts are assembled to optimize their required

functions.

The outer cylinder is maintained sufficient hardness

by heat treatment, therefore if ensures the bushings

projected travel life and satisfactory duravbility.

The ball retainer is made from steel or synthetics resin.

The steel retainer has high rigidity, obtained by heat

treat meant.

The synthetics resin retainer can reduce running noise.

The user can select the optimum type for meeting the

user's service conditions.

Structure and Features

The KOLMB linear bushing is produced from a solid

steelouter cylinder and incorporates an industrial stre-

ngth resin retainer.

The standard type of KOLMB linear bushing can be

loaded from any direction. Precision control is Possible

using only the shaft supporter, and the mounting

surface can be machined easily.

KOLMB linear bushings of each type are completely

interchangeable because of their standardized

dimensions and strict precision control. Replacement

because of wear or damage is therefore easy and

accurate.

KOLMB offers a full line of linear bushing: the stan-

dard, integral single-retainer closed types. The user

can choose from among these according to the

application requirements to be met.

1.High Precision and Rigidity

2.Ease of Assembly

3.Ease of Replacement

4.Veriety of Types

LINEAR BUSHING

Note that precision of inscribed circle diameters and outside diameters for the clearance adjustable type (…-AJ)

and the open type (…-OP) indicates the value obtained before the corresponding type is subjected to cutting

process.

Tolerance

Load Rating and

Life Expectancy

The life (L) of a linear bushing can be obtained

from the following equation with the basic dynamic

load rating and the load applied to the busha:

L:Rated life (km) fH:Hardness factor (See page5)

C:Basic dynamic load rating (N) fT:Temperature coefficient (See page5)

P:Working load (N) fc:Contact coefficient (See page5)

fw:Load coefficient

The lifespan (Ln) of a linear bushing in hours can be

obtained by calculating the travelling distance per

unit time.

The lifespan can be obtained from the following

equation if the stroke length and the number of

strokes are constant:

Lh:Lifespan s:Stroke length (m)

L:Rated life (km) n:Number of strokes per minute (cpm)

.

:L=( ) 50

f

H

r

c

p

f

c

f

w

f

. .

L=( ) 50

f

H

T

c

p

f

C

f

3

W

f

. .

(1)

(2)

Lh=

L 10

3

2 s n1 60

(

(

SLIDE UNIT

SC 20 L UU

KBA - LME SERIES SLIDE BLOCK

SME - LM SERIES OPEN SLIDE BLOCK

NO ENTRY - STANDARD TYPE

SHAFT DIAMETER

NO ENTRY - NO SEAL

U - SEAL ON ONE SIDE

UU - SEAL ON BOTH SIDES

LM F 20

UU

OP

N L

NO ENTRY - STANDARD TYPE

N - NICKEL PLATED TYPE

LM - ASIA SERIES

LME - EUROPE SERIES

LMB - ENGLISH SYSTEM SERIES

NO ENTRY - STANDARD TYPE

H - TWO SIDE CUT FLANGE TYPE

F - FOUND FLANGE TYPE

FP - PILOT PATTERN ROUND FLANGE TYPE

FC - CENTERED ROUND FLANGE TYPE

K - SQUARE FLANGE TYPE

KC - CENTERED SQUARE LANGE

KP - PILOT PATTERN SQUARE FLANGE TYPE

HP - PILOT PATTERN TWO SIDE CUT FLANGE TYPE

HC - CENTERED TWO SIDE CUT FLANGE

NO ENTRY - STANDARD TYPE

AJ - CLEARANCE ADJUSTMENT

TYPE

OP - OPEN TYPE

NO ENTRY - NO SEAL

U - SEAL ON ONE SIDE

UU - SEAL ON BOTH SIDES

NO ENTRY - STANDARD TYPE

S - SHORTEN TYPE

L - LENGTHEN TYPE

A

NO ENTRY - STANDARD TYPE

A - STEEL RETAINER

S - SHORTEN TYPE

L - LENGTHEN TYPE

SHAFT DIAMETER

SC - LM SERIES SLIDE BLOCK

KBE - LME SERIES OPEN SLIDE BLOCK

TBR - LM SERIES OPEN SLIDE BLOCK

Type number format

剩余35页未读,继续阅读

资源评论

制冷技术咨询与服务

- 粉丝: 4068

- 资源: 2万+

下载权益

C知道特权

VIP文章

课程特权

开通VIP

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- 【岗位说明】生物科技有限公司员工岗位职责.doc

- 【岗位说明】省中医院药材挑选岗位操作规程.doc

- 【岗位说明】外科护士长岗位说明书.doc

- 【岗位说明】药房药店最新岗位职责.doc

- 【岗位说明】药剂师中药师岗位职责.doc

- 【岗位说明】医美机构市场部人员岗位职责说明书.doc

- 【岗位说明】医疗投资集团组织结构及各岗位说明.doc

- 【岗位说明】医疗器械经营企业各岗位职责.doc

- 【岗位说明】医药行业制度制药公司市场部岗位职责范本.doc

- 【岗位说明】医院信息科岗位职责说明.doc

- 【岗位说明】责任护士岗位说明书.doc

- 【岗位说明】执业药师及药师岗位职责.doc

- 【岗位说明】制药企业岗位职责制.doc

- 【岗位说明】用药咨询药师职责.doc

- 【岗位说明】中草药煎药人员岗位职责.doc

- 【岗位说明】中药处理岗位操作规程.doc

资源上传下载、课程学习等过程中有任何疑问或建议,欢迎提出宝贵意见哦~我们会及时处理!

点击此处反馈

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功