没有合适的资源?快使用搜索试试~ 我知道了~

资源推荐

资源详情

资源评论

1 | P a g e

Aprilaire Dehumidifier Troubleshooting Manual

Models 1830, 1850, 1870

Table of Contents

Troubleshooting Diagnostic Codes .............................................................................................................. 2

E1 ..................................................................................................................................................... 2

E2, E3 ................................................................................................................................................ 3

E4……………………………………………………………………………………………………………………………………………….4

E5, E6 ................................................................................................................................................ 7

E7, E8 ................................................................................................................................................ 8

E9……………………………………………………………………………………………………………………………………………….9

Verifying Capacity....................................................................................................................................... 10

Water Leaks ................................................................................................................................................ 15

Fan Does Not Function ............................................................................................................................... 15

Circuit Breaker Trips ................................................................................................................................... 16

Defrost, E8, Noise……………………………………………………………………………………………………………………………..17

Parts Lists .................................................................................................................................................... 18

Electrical Schematics .................................................................................................................................. 22

Instruments you will need to complete troubleshooting:

1. Digital Multi-Meter (DMM) capability of measuring

AC and DC voltage

Resistance

Capacitance

Minimum tools needed to complete troubleshooting:

1. Torx T20 and T25 screwdrivers or driver bits

2. Small (terminal) flat head screwdriver

3. Needle nose pliers

4. Level (to troubleshoot water leak claims)

WARNING: 120-volts can cause serious injury or death. Do not touch live, exposed 120-volt

wiring or wiring terminals.

Troubleshooting must be performed by a qualified HVAC service person trained to take the

proper safety precautions when performing service on 120-volt equipment.

!

2 | P a g e

Troubleshooting Diagnostic Codes

The display on the dehumidifier will show the diagnostic code and “SERVICE REQUIRED” when the unit is

turned ON. If more than one code is detected, they are displayed consecutively:

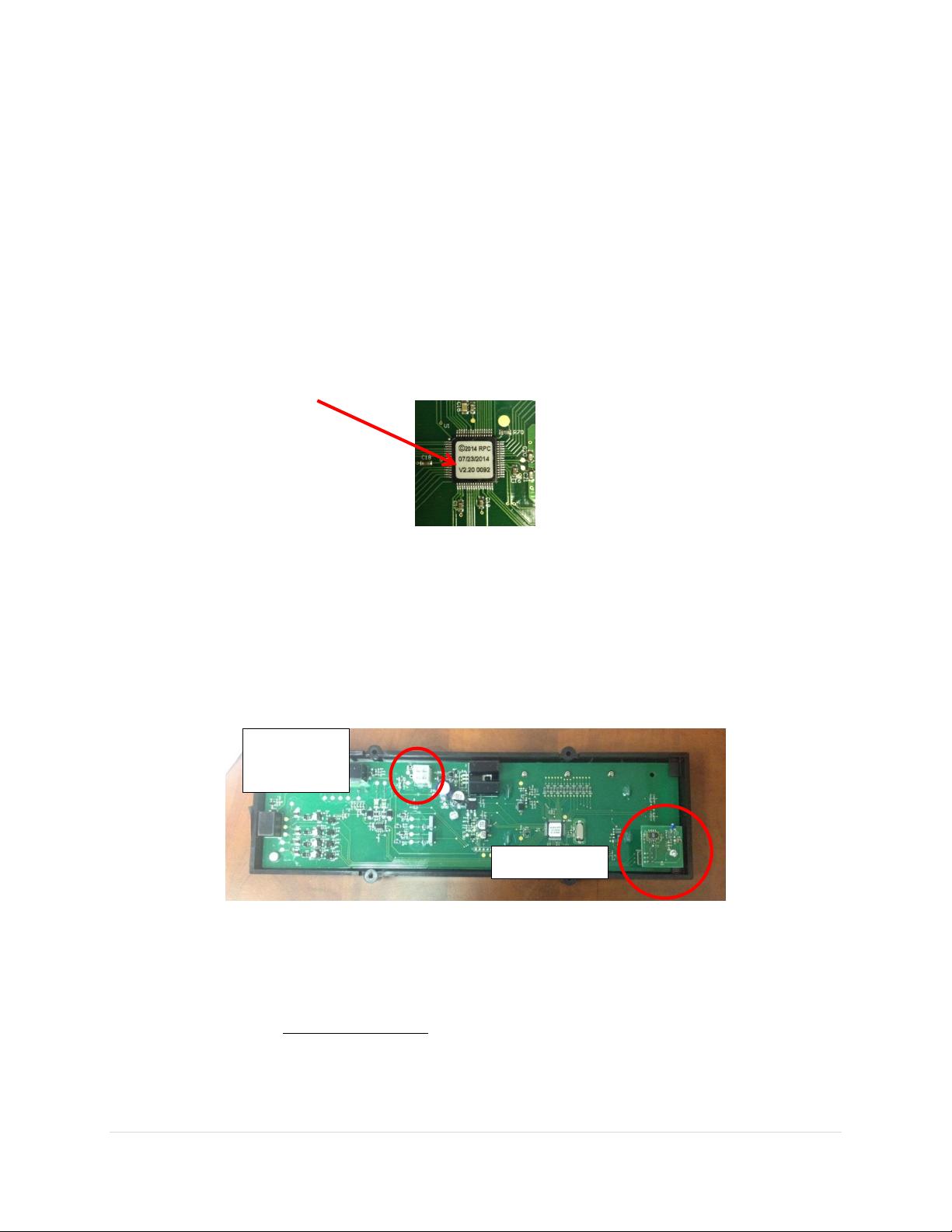

E1 - Internal %RH/Temperature Sensor Failure: The User Interface Assembly is not receiving a good

signal from the temperature/RH sensor.

1. If the unit was built before the 21

st

week of 2015 and/or has a user interface board with

Version V2.3 or earlier, determine if the unit is installed in conditions where the potential

for condensation on the sensor board could occur (see note below photos). If the unit

does not have the board with the E1 code change, replace the user interface assembly

(5445).

2. Turn off power to the dehumidifier using the ON/OFF toggle switch. Remove the User

Interface Assembly by first removing the four screws securing it to the housing. Carefully

pull the User Interface Assembly away from the housing and disconnect the three wire

cable from the back of the User Interface Assembly to be able to pull the User Interface

Assembly totally away from the dehumidifier. The small circuit board screwed to the

back of the User Interface Assembly is the sensor board. Replace the RH Sensor board

(5460).

NOTE E1 Code Change: Beginning with serial number 212015A16241 the code was changed to V2.4. E1

and E8 will no longer occur when in External & Single Zone Mode. When in this mode combination, the

dehumidifier will not check the inlet air condition and will not use the on board sensor board to sample

the indoor temperature or humidity. This change is to eliminate issues in geographic regions where the

dehumidifier is installed with external control, in an environment that has periods of cold temperatures

and there is still a dehumidification demand. Condensation can form on the sensor board and sensors,

causing an E1 fault.

3-wire

connector

Sensor Board

3 | P a g e

E2 – High Refrigeration Pressure: The temperature of the discharge line exceeds 190°F. This is self-

correcting unless it occurs for five consecutive compressor starts. This is usually caused by

the inlet air temperature being too high (i.e. greater than 100°F), or very low airflow through

the dehumidifier.

1. Turn the ON/OFF toggle switch OFF to reset the diagnostic code.

2. If the fan is not working, see “Fan does not Function” section on page 15.

3. Consider the following for the application:

1. If ducting to the HVAC system, make sure the inlet to the dehumidifier is not ducted

to the supply side of the HVAC system.

2. Attic installations – Inspect the ductwork attached to the inlet of the dehumidifier for

leaks if the ambient temperature is high.

3. Ventilation applications – High temperatures may be offset by mixing air from the

home into the dehumidifier.

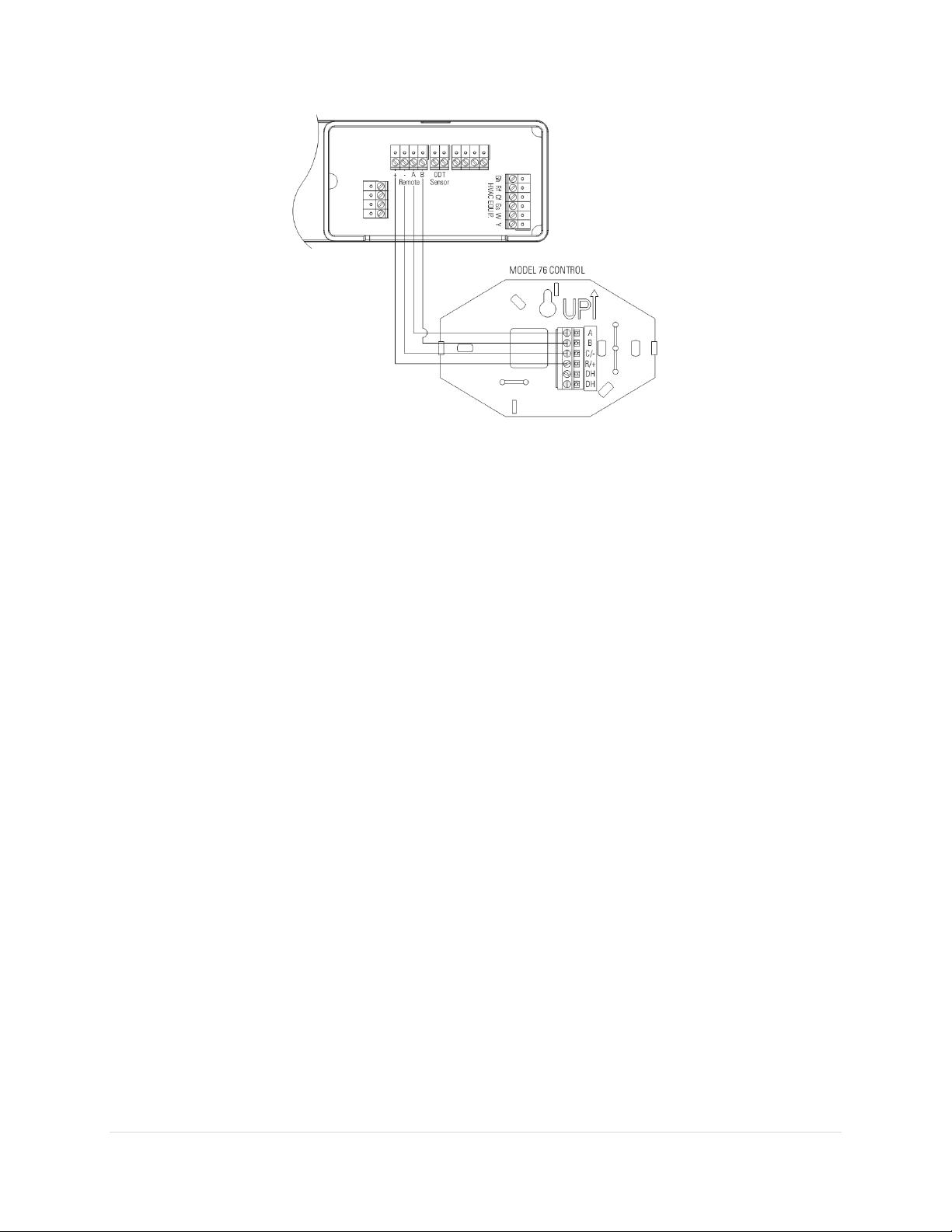

E3 – Model 76 Remote Control Communication Loss: A Model 76 control, wired to the Remote

terminals of the User Interface Assembly, had communication, but has now stopped

communicating.

Note: For E3 to be displayed, the method of control had to have been set up for a Remote

control. This is done by selecting Remote Enabled in the set-up menu.

1. Use the color of the wire connected to the A, B, + and – (on the Model 76, the “+” and “-“

terminals are labeled “R/+” and “C/-“) terminals on both the base of the Model 76 and

the dehumidifier User Interface Assembly to verify that they are wired correctly. Make

sure the terminal screws on both the User Interface Assembly and the Model 76 base are

tight.

2. Remove the Remote terminal block from the User Interface Assembly and measure the

DC voltage across the + and – pins on the User Interface Assembly – this should read

approximately 35 V DC (±3V for voltage variation and load). If there is 0 volts, the User

Interface Assembly (5445) must be replaced. If in range, reinstall the Remote terminal

block.

3. If connections are correct and secure, turn off the dehumidifier and remove the Model

76 control. Use a short section of 4-wire cable to reconnect the Model 76 to the User

Interface Assembly to see if there is a problem with the existing wire. Turn the

dehumidifier back on. If the “E3” code continues, the Model 76 must be replaced, if the

code is gone, then the wire between the Model 76 and the dehumidifier must be

replaced.

4 | P a g e

E4 – Insufficient Capacity: The temperature of the suction line, as sensed by the Frost Sensor, has not

dropped at least 5°F in 20 minutes from the temperature it was when the compressor

started. One reason this would happen is if the dehumidifier went from a cold condition to a

warm condition very quickly (e.g. coming off a cold truck into a warm home) AND there was

little airflow through the unit prior to the compressor starting. If this is possibly the case,

then allow the dehumidifier to acclimate to the conditions for one hour before restarting.

Other reasons this code would be displayed is if the compressor is not running or if the

refrigeration system is not operating properly.

1. Use the ON/OFF button on the User Interface Assembly to turn the mode to OFF, then

flip the ON/OFF toggle switch to OFF, to reset the diagnostic code.

2. Turn the ON/OFF toggle switch back ON. With the mode still OFF, Press and hold the

MODE button and ON/OFF button to enter the Installer Test Mode.

3. The fan will run for 3 minutes with the display showing “AIR SAMPLING” and “TEST”, and

the inlet air RH. After three minutes, the “DEHUMIDIFYING” will replace “AIR SAMPLING”

on the display and the compressor will start – you should be able to hear this. The

compressor will run for one minute, and then the display will show “TEST DONE” and

return to the OFF mode.

If the compressor didn’t start (go to step 4), there is an electrical issue to address. If the

compressor did start (go to step 5), then you will need to verify that the refrigeration

system is working properly.

5 | P a g e

4. If the compressor doesn’t start

a. Turn the ON/OFF toggle switch to OFF.

b. Remove the panel on the side of the dehumidifier where the drain tube comes out,

and then remove the insulation piece. Inside the dehumidifier, remove the

electrical box cover.

c. Verify that the brown and orange wires are connected to the Internal Control board.

Verify that two brown wires are connected to one pole of the run capacitor and one

red wire is connected to the other pole. Give each wire a light tug to make sure all

connections are sound.

If any of the wires were disconnected, place the side panel back on (do not

secure with screws yet), and repeat steps 2 and 3 above. If it starts, go to step 5

to verify the performance of the refrigeration system before leaving. If it still

does not start, continue to the next step (d.).

If none were disconnected, continue to the next step (d.).

d. Turn the ON/OFF toggle switch back ON. With the side panel still off, stay clear of

the fan motor and repeat steps 2 and 3 above.

e. If the COMP LED is on but the compressor is not, remove the locking tab

connectors from the compressor BRN and ORG terminals and measure the voltage

at the pins on the Internal Control board:

If the voltage is 120VAC (nominal) then the problem lies with the run capacitor,

the connections at the compressor or the current limiting switch under the

compressor cap. Turn the ON/OFF toggle switch OFF and unplug the unit.

o Disconnect the wires connected to the run capacitor and the orange wire

connected to the Internal Control board. Measure the capacitance of the

run capacitor – it should be 45 microfarads ± 5% for the 70/95pt or 50

microfarads ± 5% for the 130pt. If not, replace the capacitor (5458 70/95pt

or 5594 130pt).

o Measure the resistance across the compressor harness wires. Actual

measurements may be a little different, but should be approximately:

Run Capacitor Poles

剩余22页未读,继续阅读

资源评论

制冷技术咨询与服务

- 粉丝: 4128

- 资源: 2万+

下载权益

C知道特权

VIP文章

课程特权

开通VIP

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

- 有清华大学2月最新汇报ppt及录音,下载后可发送全套

- esp32单片机,检测马达转速项目提供源码下载

- 前端框架-Vue2初体验

- 三菱FX3U PLC与E740变频器Modbus RTU通讯案例:启停控制、频率调节及参数读取的编程实现,三菱FX3U PLC与变频器Modbus RTU通讯控制案例:实现启停、频率设定与数据读取功能

- DeepSeek大模型安装助手简介

- 机器学习课程设计基于Python的实现自动化垃圾邮件过滤项目源代码+已标记数据集

- AI推理模型DeepSeek-R1网页端&API使用指南:性能特点及实际应用案例解析

- 毕业设计基于Python的Django-html基于深度学习的音乐推荐方法研究系统源码(完整前后端+mysql+说明文档+LW+PPT).zip

- iozone自动化测试脚本

- PyQt5+Yolov8车牌检测系统

- 毕业设计基于Python的Django-html基于循环神经网络的情感分类系统源码(完整前后端+mysql+说明文档+LW+PPT).zip

- iozone3-507工具

- csdn积分获取,看看能不能获取积分

- usb通信-Linux-遍历usb

- Go语言学习指南:从入门到精通全面掌握后端开发高效语言

- 雷达测距测速成像+线性调频连续波雷达+仿真分析

资源上传下载、课程学习等过程中有任何疑问或建议,欢迎提出宝贵意见哦~我们会及时处理!

点击此处反馈

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功