没有合适的资源?快使用搜索试试~ 我知道了~

KUKA_FRI_from_WS_Proceedings_ICRA2010.pdf

需积分: 9 10 下载量 196 浏览量

2018-09-12

14:22:24

上传

评论

收藏 474KB PDF 举报

温馨提示

Abstract—The KUKA lightweight robot (LWR) provides many unique features for robotic researchers. To give full access to these features, a new interface was developed that gives direct low-level real-time access to the KUKA robot controller (KRC) at high rates of up to 1 kHz. On the other hand, all industrial-strength features, like teaching, motion script features, fieldbus I/O and safety are provided. Using standard UDP socket technology, the user is not limited to one specific runtime system. This paper describes the capabilities of the interface, the practical realization within the LWR control architecture and first applications of the interface.

资源推荐

资源详情

资源评论

Abstract—The KUKA lightweight robot (LWR) provides

many unique features for robotic researchers. To give full ac-

cess to these features, a new interface was developed that gives

direct low-level real-time access to the KUKA robot controller

(KRC) at high rates of up to 1 kHz. On the other hand, all in-

dustrial-strength features, like teaching, motion script features,

fieldbus I/O and safety are provided. Using standard UDP

socket technology, the user is not limited to one specific runtime

system. This paper describes the capabilities of the interface,

the practical realization within the LWR control architecture

and first applications of the interface.

I. I

NTRODUCTION

The KUKA lightweight robot (LWR) (Figure1) is the lat-

est outcome of a bilateral research collaboration between

KUKA Roboter GmbH [1] and the Institute of Robotics and

Mechatronics at the German Aerospace Center (DLR) [2].

Due to its unique features like high payload ratio, program-

mable active compliance and torque sensor feedback, it en-

ables researchers and automation engineers to develop new

industrial and service robot applications. From the begin-

ning, one important aspect of the LWR product development

was to make features available from the KUKA controller

and its integrated scripting language (KUKA Robot Lan-

guage, KRL). This way, every industrial robot programmer

who is used to program standard industrial KUKA robots, is

able to program the LWR. KRL was extended to make avail-

able the LWR features, such as impedance control [3], which

is not available for standard robots. Also, the “all-in-a-box”

controller hardware was developed, so that power supply,

controller board and safety logic are in a common housing.

While this kind of approach fits the requirements of industry,

researchers have a more elaborate desire w.r.t. to such an

arm. To investigate the requirements of the research commu-

nity KUKA developed a questionnaire within the EC-funded

project BRICS – Best practice in robotics [4].

This paper is organized as follows: First the requirement

analysis will be presented that motivated the development of

the Fast Research Interface (FRI). Section III will explain the

FRI in more detail. The control system architecture and its

implementation are presented in sections IV and V, respec-

tively. First applications of the FRI are shown in section VI

before the paper is concluded in section VII.

Günter Schreiber is with KUKA Roboter GmbH, Augsburg, Germany

(e-mail: GuenterSchreiber@kuka-roboter.de )

Andreas Stemmer is with DLR, Institute of Robotics and Mechatronics,

Oberpfaffenhofen, Germany (e-mail: andreas.stemmer@dlr.de )

Rainer Bischoff is with KUKA Roboter GmbH, Augsburg, Germany

(e-mail: RainerBischoff@kuka-roboter.de )

Figure 1: KUKA Lightweight Robot (LWR) with KUKA Robot Controller

(KRC 2lr) and KUKA Control Panel (KCP).

II. R

EQUIREMENT

A

NALYSIS

A. The BRICS Project

The EC-funded project BRICS – Best practice in robotics

– provided the framework for the requirement analysis. The

prime objective of BRICS is to structure and formalize the

robot development process itself and to provide tools, mod-

els, and functional libraries, which allow reducing the devel-

opment time by a magnitude. BRICS is working together

with academic as well as industrial providers of robotics

“components” (hardware and software), to identify and

document best practices in the development of complex ro-

botics systems, to refactor (together) the existing components

in order to achieve a much higher level of reusability and

robustness, and to support the robot development process

with a structured tool chain and code repository.

The first target group of the BRICS project is the robotic

research community. BRICS aims at offering hardware with

a consistent set of harmonized, well-defined and docu-

mented, public APIs, and an integrated development envi-

ronment. BRICS will help researchers to design and make

operational complex robotic systems with minimal effort and

avoid so-called “from scratch developments”. BRICS in-

volves the community through questionnaires, workshops

and research camps.

The Fast Research Interface for the KUKA Lightweight Robot

Günter Schreiber, Andreas Stemmer, and Rainer Bischoff

15

B. Use Cases

In a first step, use cases were defined and discussed with

the robotics community using a questionnaire. The use cases

were structured according to the demands of typical applica-

tions as follows:

1) Standard industrial application

• pre-programmed task

• external interface (if any) only necessary for syn-

chronization

2) Advanced industrial application with non-continuous

feedback control

• pre-programmed task

• external sensors, but only discrete measurements

• no continuous feedback control (“look-then-move”)

• industrial controller does: path planning, interpola-

tion, inverse kinematics, etc.

• simple interface sufficient (exchange of data with-

out real-time requirements)

• real-time / non-real-time vs. (non-)continuous are

two different issues

3) Advanced industrial application with continuous feed-

back control

• pre-programmed task

• external sensors used for feedback control

• examples: cameras, FT sensor, …

• major part of application is programmed on indus-

trial controller

• sensor data processing is programmed outside robot

controller

• low cycle time and minimal dead time of feedback

control is important for sensor-based control

real-time interface: exchange of data in fixed time

intervals (e.g., interpolation cycle time)

4) Research outside robotics field:

• robot is used for research outside the field of robot-

ics, e.g., robot is used to automate measurements

• use cases 1-3 are applicable

5) Robotics research – system / application level:

• robot is used as part of a larger system to realize

and evaluate new applications in the area of cogni-

tive systems, service robotics, etc.

• integration of robot controller in other systems

should be easy

• functionality of robot controller should be control-

lable from outside

6) Robotics research – control level:

• robot is used to implement and evaluate new robot-

ics algorithms in the area of control, e.g., inverse

kinematics, dynamics, force control, …

• robot control at low level (real-time constraints)

7) Robotics research – haptics:

• robot is used as haptic input device (e.g., for virtual

reality) or slave for tele-presence systems; high sen-

sitivity for force control (< 10 N)

• control of robot systems at lowest level possible

(real-time constraints)

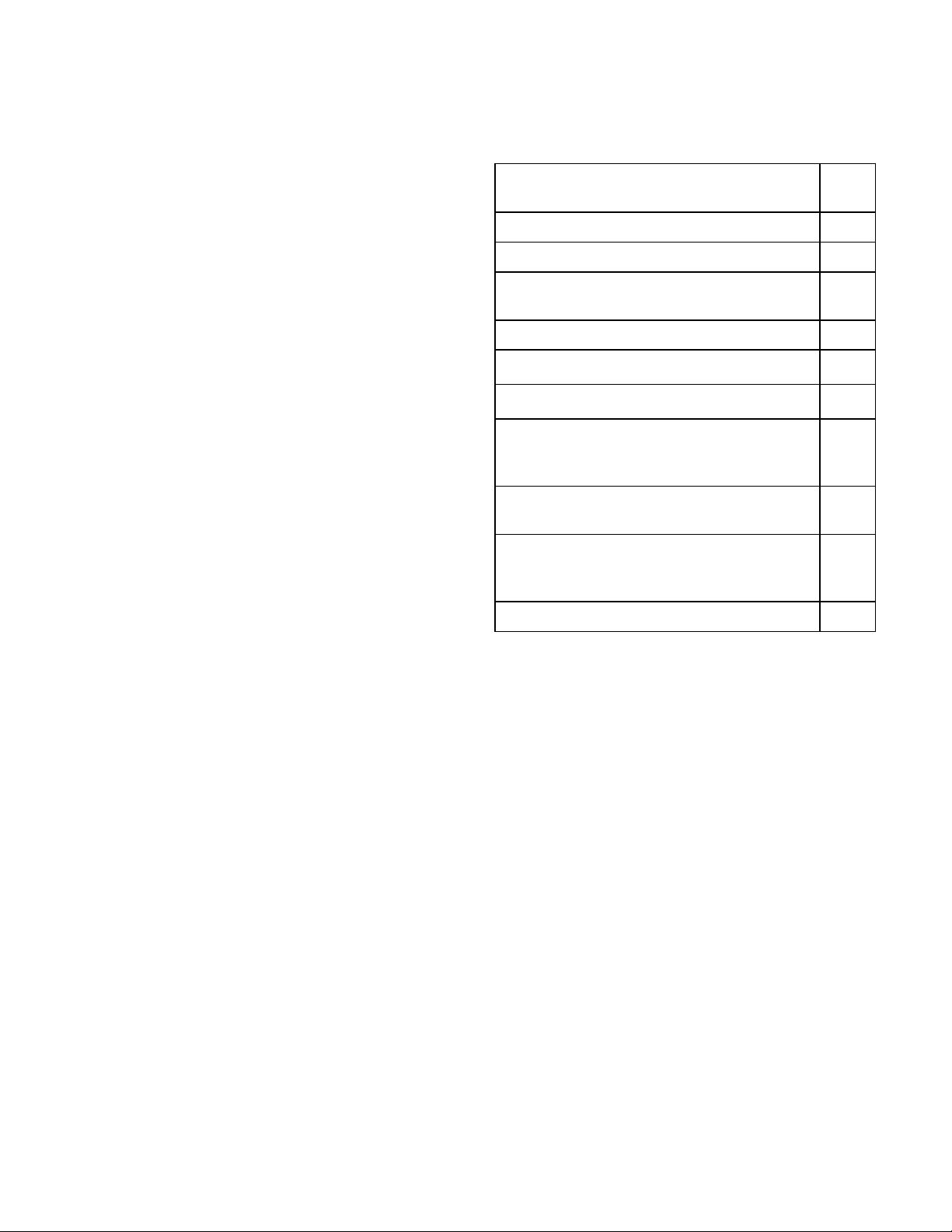

C. BRICS Questionnaire and Use Case Analysis

Researchers were asked in what kind of applications they

would want to use the LWR. The following table gives an

overview of some of the answers along with a classification

according to the use cases defined above:

Attach a novel hand & use it for a project for pick-

ing in an industry application

2, 3

Visual servoing 3, 6

Line drawing – calligraphic text painting 2, 3

Peg in hole, pegs have small clearance, put a key

into a lock & take it out

2, 3

Vibration damping 6

Like to implement „our own control algorithms“ 6

Haptic input device for virtual / augmented reality 7

Advanced assembly and manufacturing, adapt the

robot in real-time with additional sensor/process

model information

3

Pick and place task in office or home, including

simple manipulation

5

Instrument carrier, with controllability of redun-

dancy and with 10 Hz mechanical bandwidth, but

with 1 kHz sensor interface (read access)

6

10 Hz multi-TCP „force“ control (or other sensor) 6

Table 1: Excerpt from BRICS questionnaire: selected answers from

potential LWR users.

The questionnaire revealed that there is a huge variety of

ideas on how to use the LWR. Still, the answers could be

classified in two major groups: The first group contains those

customers with applications in use cases 1-4. These can be

satisfied with the current industrial controller. Here, it be-

came clear to KUKA that it is necessary to inform users bet-

ter on the features of the system and teach them how to use

them. The second group contains use cases 5-7. Here, the

customers want to control the robot at the lowest level possi-

ble. It is interesting to see that some users intend to improve

or research on algorithms that are already quite mature and

integrated in the KUKA controller, such as standard motion

control algorithms or more advanced ones, such as vibration

damping. Here, it also seems necessary to better inform users

about the features of the system that they do not re-invent the

wheel. Nevertheless, to be able to realize the customer ideas

– including the most challenging use case 7, haptics, in

which nothing can be anticipated, it deemed necessary to

develop a generic interface that allows access at different

levels and control rates without loosing the strengths of an

industrial controller.

16

剩余6页未读,继续阅读

资源评论

小弧光

- 粉丝: 63

- 资源: 15

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜最新资源

资源上传下载、课程学习等过程中有任何疑问或建议,欢迎提出宝贵意见哦~我们会及时处理!

点击此处反馈

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功