respect to criterion C

UNPEMq

, the A

UNPEMq

has the reciprocal

value (S

UNPEMqsp

) when compared to C

UNPEMps

.

4. Set up supplier comparison, this process is identical to the

procedure used to develop the criteria comparison matrix.

The only difference is that there is a supplier comparison

matrix for each criterion. Therefore, the decision maker

compares each pair of suppliers with respect to the tangible

criterion, and all suppliers must be compared pair-wise for

each criterion. The decision maker uses own personal

judgement to make the requi red pair-wise comparisons ,

compares each pair of suppliers with respect to the tangible

criterion. This is repeated for the whole criteria, and all

suppliers must be compared pair-wise for each criterion.

5. Calculate the final results according to the rating marks from

criteria and supplier comparison respectively. This is

constructed by using the relative importance of the

alternatives in terms of each criterion, nam ely, the CA

matrix as shown in Table 1 (where C is the number of criteria

and A is the number of alternative), and the results of these

multiplications are added together to compute the final

scores. According to Satty, the best supplier alternative is the

one that satisfies the following expression:

SUNPEM ¼ max

X

N

j¼1

UNPEMij W j; i ¼ 1; 2; 3 ; ...

where N is the number of decision crite ria, UNPEMij is the

actual value of the ith alternative in terms of the jth criterion

under the unique focus strategy with the development direc-

tion of new product in an existing market, and Wj is the

weight of importance of the jth criterion. The sum of

SUNPEM is equal to one. In this case, the greater scores

of suppliers, the better is a potential supplier under that

condition.

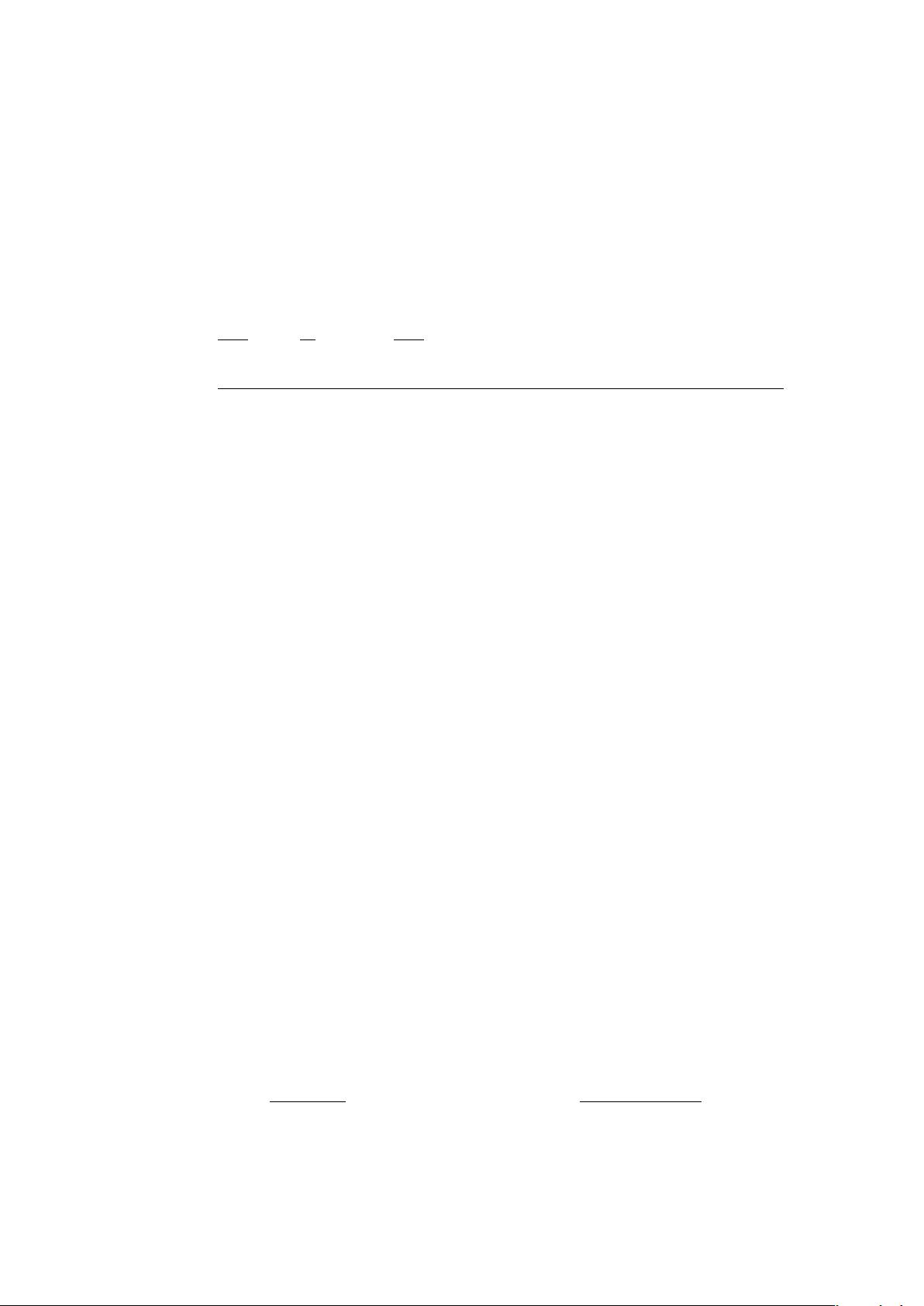

The relative importance of the supplier selection factors will

depend upon the strategies with product market position which

the decision marker is pursuing. When a decision marker

pursues a unique focus strategy, for example, strong R&D, high

quality and technical capability may be more important than

price, delivery and location. Conversely, a decision marker

would probably emphasize price and location more than the

other factors if the Cost focus strategy is pursued. Taking the

NPEM and the EPNM matrices with an example to illustrate the

procedures above will be shown in Section 4.

2.4. Web-based technology utilized in the system

Lack of interoperability is a vital bottleneck for many Web-

based systems. In order to enhance the capability of this

supplier selection system, it is necessary to utilize the state of

the art Web-based technology to develop a heterogeneous

environment for people who are involved in the process of

supplier selection . Web Services and J2EE technologies have

been chosen to implement the system.

Web Services technology was developed and widely

supported by many major high–tech vendors, such as IBM,

Sun Microsystems and BEA Systems [30–32]. It has been

considered as an excellent technology to solve distributed

computing challenges for manufacture in the Internet area. The

Web Services can take the advantages of distributed operating

systems and use computing power efficiently and cooperatively.

It provides a user-centric computing environment that integrates

multiple applications running on various operating systems

behind the corporate firewall. [29–32]. The Extensible Markup

Language (XML), Simple Object Access Protocol (SOA), Web

Services Description Language(WSDL) and Universal Descrip-

tion, Discovery and Integration (UDDI) standards form the

backbone of Web Services technology [29–32].

Due to concurrency, consistency, reliability, security and

distribution issues, it is crucial to apply right technologies for

the Web Services implementation. The JavaTM 2 Platform,

Enterprise Edition (J2EETM) provides architecture for

distributed enterprise appl ications. As the member of the

J2EE family, several middle-tier technologies included

Servelts, JavaServer Pages(JSPs), and Enterprise JavaBean-

s(EJBs) have been utilized in the implementation of this Web

Sevices-based supplier selection system [29–35].

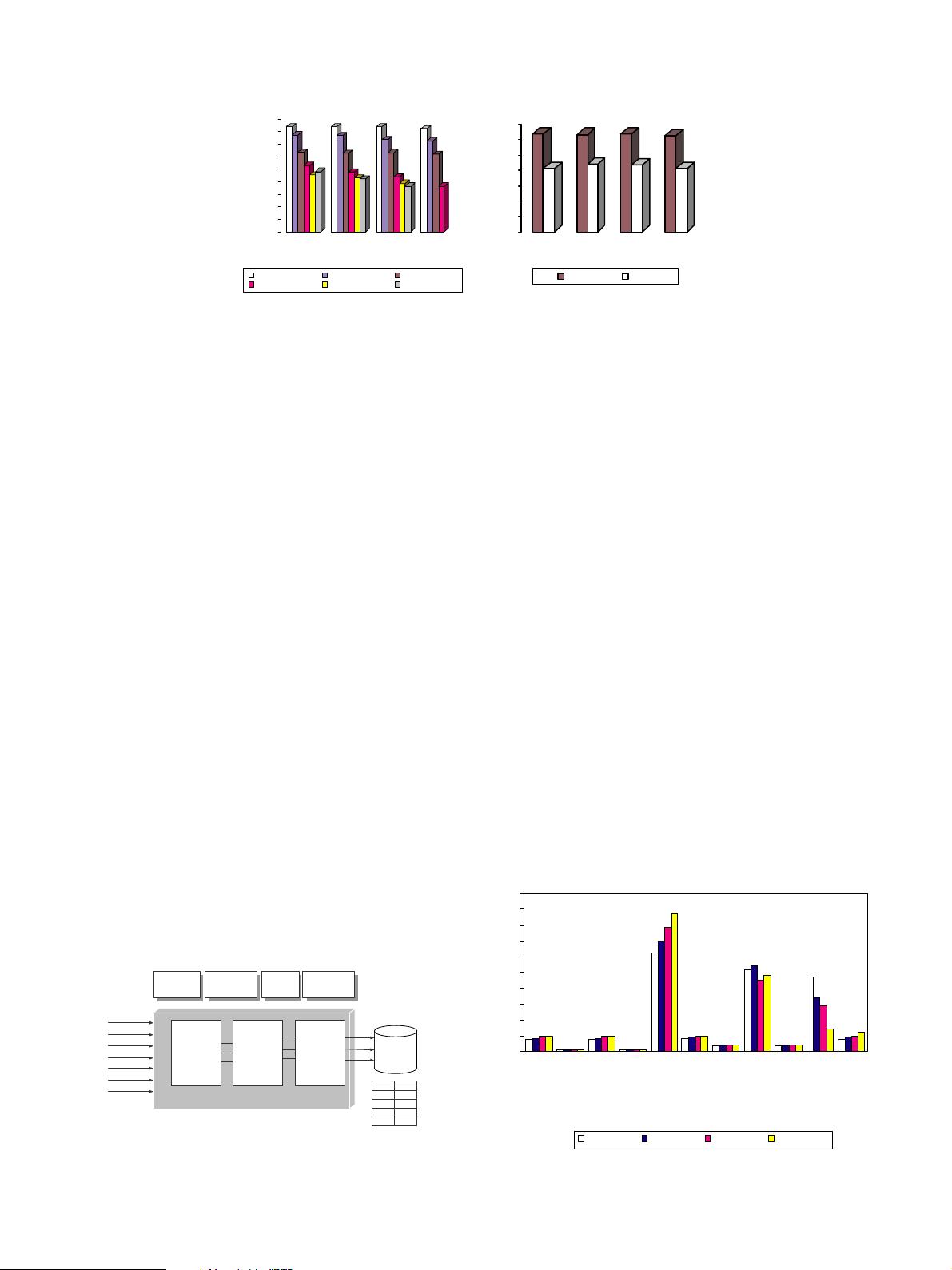

3. The WMPSS system

3.1. System overview

The system contains two major parts: Reference system and

CSPMP (competitive strategies with product market positions)

matrices. The purpose of this system is to aid manufacturers to

effectively make decision for supplie r selection and strengthen

collaboration between people of all functions who are involved

in the procedure of product development. The system breaks

the barriers between geographically dispersed teams and

partners who are using incompatible computing languages and

equipment, which enables firms to be flexible identify and to

efficiently shift their business or production directions under

the turbulent external environment. This will enhance

manufacturers’ efficiency and flexibility, and allow them to

avoid or minimize risk when external conditions change . The

main features of this system different from existing supplier

selection systems are: (1) the ability to access and evaluate

suppliers’ information immediately regardless of geographic

location or IT infrastructure, this is achieved by combination of

Web Services with J2EE technology which enable the system to

have following features: scalability, heterogeneity and reusa-

bility; (2) based on the survey results, twelve pre-defined

matrices that integrate CSPMP to help firms to adjust their

direction in a strategic and reliable manner; (3) an accurate and

reliable comparison and assessment of suppliers based on the

pre-defined matrices, AHP approach and Web-enabled tech-

nologies, and (4) the ability to effectively take various business

strategies and product market positions into consideration.

The working procedure shown in Fig. 1 is operated within

the Web Services oriented environment. Team members play

different roles in the process of product design; each of them is

a specialist in one or more areas, they may located dispersedly

with different privilege o f accessing the supplier selection

J. Hou, D. Su / Computers in Industry xxx (2006) xxx–xxx4

+ Models

COMIND-1922; No of Pages 12

Please cite this article as: Jiachen Hou, Daizhong Su, Integration of Web Services technology with business models within the total product

design process for supplier selection, Computers in Industry (2006), doi:10.1016/j.compind.2006.04.008

tolo航空订票系统.zip (14个子文件)

tolo航空订票系统.zip (14个子文件)  tolo航空订票系统

tolo航空订票系统  文献综述 航空公司国内机票售票系统-080609.doc 28KB

文献综述 航空公司国内机票售票系统-080609.doc 28KB 开题报告 航空公司国内机票售票系统-080609.doc 34KB

开题报告 航空公司国内机票售票系统-080609.doc 34KB 文献综述 航空公司国内机票售票系统.doc 50KB

文献综述 航空公司国内机票售票系统.doc 50KB 任务书 航空公司国内机票售票系统-080609.doc 14KB

任务书 航空公司国内机票售票系统-080609.doc 14KB 文献翻译 航空公司国内机票售票系统.doc 42KB

文献翻译 航空公司国内机票售票系统.doc 42KB 航班网上订票系统.doc 29KB

航班网上订票系统.doc 29KB 1-Performance prediction of component-based applications.pdf 323KB

1-Performance prediction of component-based applications.pdf 323KB 航空售票系统课后代码.rar 9.1MB

航空售票系统课后代码.rar 9.1MB 毕业论文 航空公司国内机票售票系统.doc 392KB

毕业论文 航空公司国内机票售票系统.doc 392KB 开题报告 航空公司国内机票售票系统.doc 57KB

开题报告 航空公司国内机票售票系统.doc 57KB tolo航空公司营业员柜台系统.zip 2.68MB

tolo航空公司营业员柜台系统.zip 2.68MB 毕业论文 航空公司国内机票售票系统.doc 480KB

毕业论文 航空公司国内机票售票系统.doc 480KB 航空订票系统毕业设计.doc 18KB

航空订票系统毕业设计.doc 18KB 2-Integration of Web Services technology with business models within.pdf 547KB

2-Integration of Web Services technology with business models within.pdf 547KB

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功

评论0