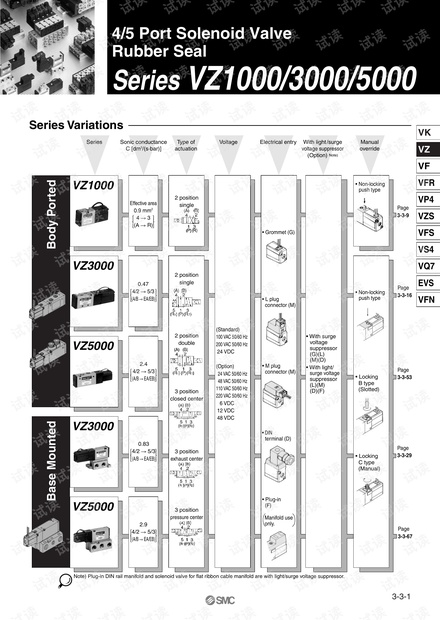

日本和泉VZ1000.3000.5000系列4/5通弹性密封电磁阀使用手册.pdf

需积分: 10 85 浏览量

2019-10-15

16:34:34

上传

评论

收藏 11.27MB PDF 举报

weixin_38744435

- 粉丝: 370

- 资源: 2万+

最新资源

- AIS2024 valid

- 最入门的爬虫代码 python.docx

- 爬虫零基础入门-爬取天气预报.pdf

- 最通俗易懂的 MongoDB 非结构化文档存储数据库教程.zip

- 以mongodb为数据库的订单物流小项目.zip

- 腾讯云-mongodb数据库, 项目部署.zip

- 腾讯 APIJSON 的 MongoDB 数据库插件.zip

- 理解非关系型数据库和关系型数据库的区别.zip

- 操作简单的Mongodb网页web管理工具,基于Spring Boot2.0支持mongodb集群.zip

- tms-mongodb-web,提供访问mongodb数据的REST API和可灵活扩展的mongodb web 客户端.zip

资源上传下载、课程学习等过程中有任何疑问或建议,欢迎提出宝贵意见哦~我们会及时处理!

点击此处反馈