person determine all possible defects. Therefore, certain methods

must be devised to solve the problem of subjectivity in quality evalu-

ation due to the limitations of human perception.

Previous researches have attempted overcome the limitations of

the subjective evaluation of visual quality inspection by human in-

spectors [8–18]. These research works developed an automatic proce-

dure replacement using computer vision and image-processing

technologies to detect damage positions and quantify defect level.

Moreover, the image-processing technique can be integrated with

tools for data collection and transformation such as digital camera,

wireless sensors, wireless scanner, PDA or mobile phone to automate

the process of damage inspection or monitoring. The previous re-

searches have studied to apply in both structural work and architec-

tural work. For example, the damage inspection in several concrete

structures by using digital image processing technique, Georgopoulos,

Loizos and Flouda [8], and Lee [9] conducted studies to quantify

defects and to classify crack types in road infrastructures. The results

of these studies helped to optimize infrastructure maintenance strate-

gies during the operation stage. Digital image processing (DIP) is a

popular information technology in this field. In the same, Yu, Jang

and Han [10] studied to propose a system by using digital image pro-

cessing technique for detecting and measuring cracks in a tunnel to

provide objective crack data to be used in evaluating safety. Furuta,

Namura, Nakatsu, Hattori, and Adachi [11] applied digital image pro-

cessing to assess damage level of bridge. Lee, Chang and Skibniewski

[12] studied the inspection of the deterioration of a steel bridge

coating. The study used digital image processing technique to quantify

the amount of rust on the steel surface. Moreover, the image proces-

sing can be applied to inspect the defect level in the architectural

work. For example, Zhu and Brilakis [13] studied to detect air pockets

in architectural concrete for quality assessment. Mostly, the previous

researches intended to apply image-processing technique to detect

defect positions on materials such as wood defect classification, de-

fects on tile (cracks, bumps, depressions, holes, dirt, drops, water

drop, ondulations, colour and texture) [14–18].

However, few researchers have focused on evaluating the inten-

sive defect level of the subjective attributes of aesthetic issues during

the construction stage. The subjectivity of human perception

can cause several problems. For example, some work items in archi-

tectural work cannot quantify the amount of a defect by a human vi-

sual inspection for supporting decision on quality, although there is a

standard specifying in the contract document. The decision making

depends on the individual experience and is unreliable. These can

lead to conflicts about what is an acceptable judgment of the defect

level. Therefore, this study aims to develop a system for evaluating

aesthetic defect levels by using within an organization to reduce

these problems.

This paper presents an innovative system of defect detection and

quantification. The system is able to specify the defect positions and

quantify the defect values to support the subjective visual quality in-

spection of the aesthetics of an architectural work. This method is

based on defect feature analysis and quantifies the defect value in dig-

ital images using a digital image processing technique. The proposed

system increases the reliability of aesthetic judgments by reducing

the input of human subjective judgment. We chose the inspection

of tiling work as the case study for developing the prototype of the

system. After giving a brief background of the problem and the previ-

ous works in this section, the content of this paper describes the con-

ceptual framework of the application of the proposed system and the

methodology of the system's development. In addition, it includes a

field verification of the potential and accuracy of the developed proto-

type system by comparing the results of human inspections and those

of the proposed system.

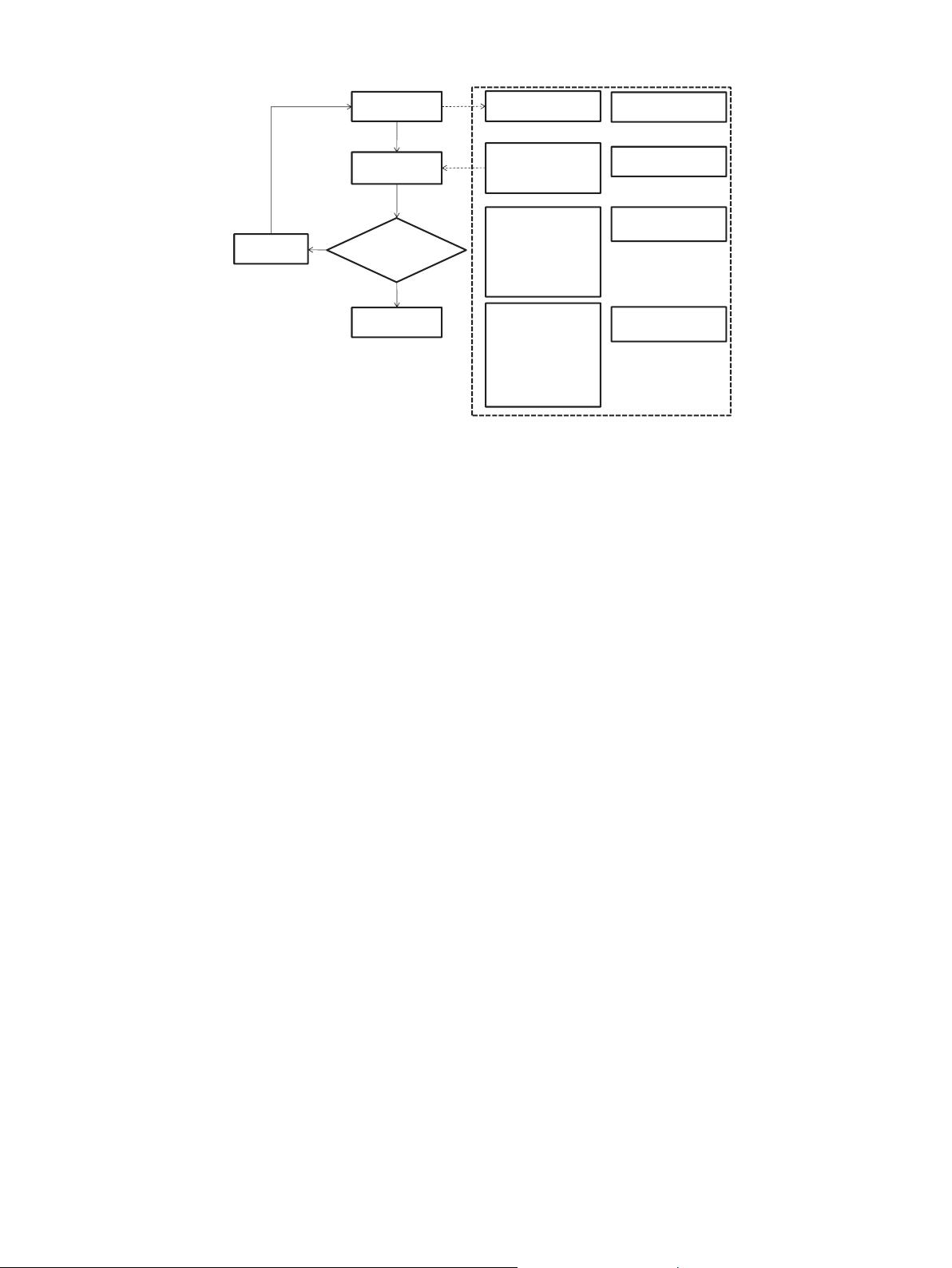

2. Principles of the digital image processing technique

Digital image processing in computer vision is a computerized

process that helps to enhance the properties of an image into a usable

form with an objective and easier feature analysis of images [19]. The

interest in digital image processing methods stems from two princi-

pal areas of application. These are the improvement of pictorial infor-

mation for human interpretation and the processing of scene data for

autonomous machine perception [20]. Digital image processing can

be roughly divided into four levels of the computerized process in a

continuum that is shown in Fig. 2 . Representations are depicted as

shaded rectangles. Two levels are often distinguished; these are

low-level image processing and high-level image understanding

[19,21,22].

(1) Low-level processing involves primitive operations that consist

of image acquisition, image compression and a pre-processing

method for noise filtering, edge extraction and image sharpen-

ing or the enhancement of certain object features that are

relevant to understanding the image.

(2) High-level processing attempts to imitate human cognition

(making sense of the image) and the human ability to make

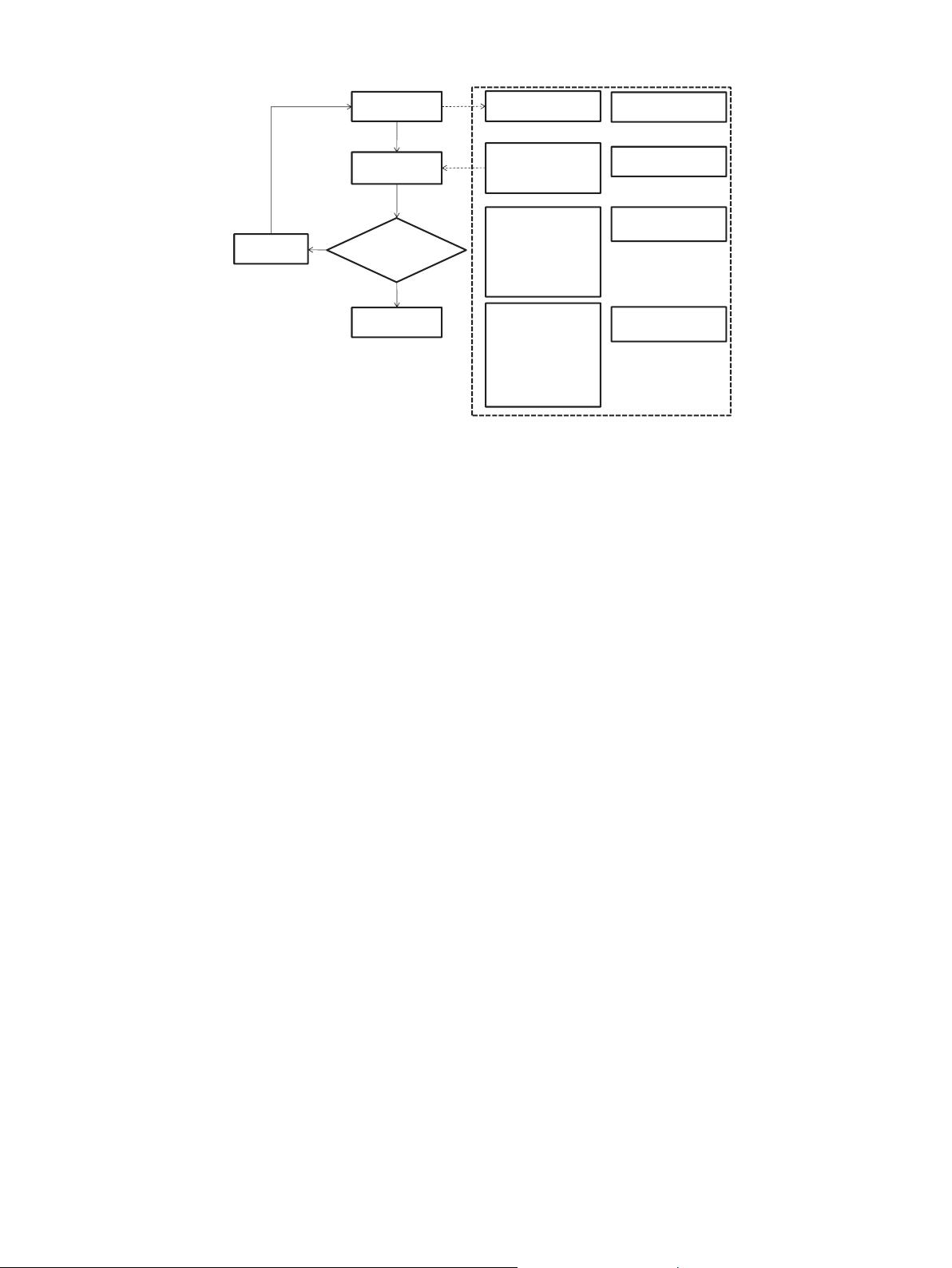

Inspection

Defect

quantification

(Measurable)

Acceptable

defect level

evaluation

Not pass

Correction

Continue next

process

Assessment tools

(Mechanical

instrument)

Contract document

- Standard

- Sampling

- Drawing

- Specification

pass

(Measurable)

(Subjective)

Visual

Individual experience

(Subjective)

Relate to

-Material

requirement

-Construction

requirement

-Functional

requirement

Aesthetic issue

in architectural work

Measurable attribute

Subjective attribute

Fig. 1. Quality evaluation in inspection processes.

161C. Laofor, V. Peansupap / Automation in Construction 24 (2012) 160–174

maikel0maikel2014-06-18对视觉识别 有很大帮助,谢谢分享!

maikel0maikel2014-06-18对视觉识别 有很大帮助,谢谢分享! 我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜

信息提交成功

信息提交成功