没有合适的资源?快使用搜索试试~ 我知道了~

资源推荐

资源详情

资源评论

4 is harder than 6:

Inverse kinematics for underactuated robots

Peter Corke

February 2014

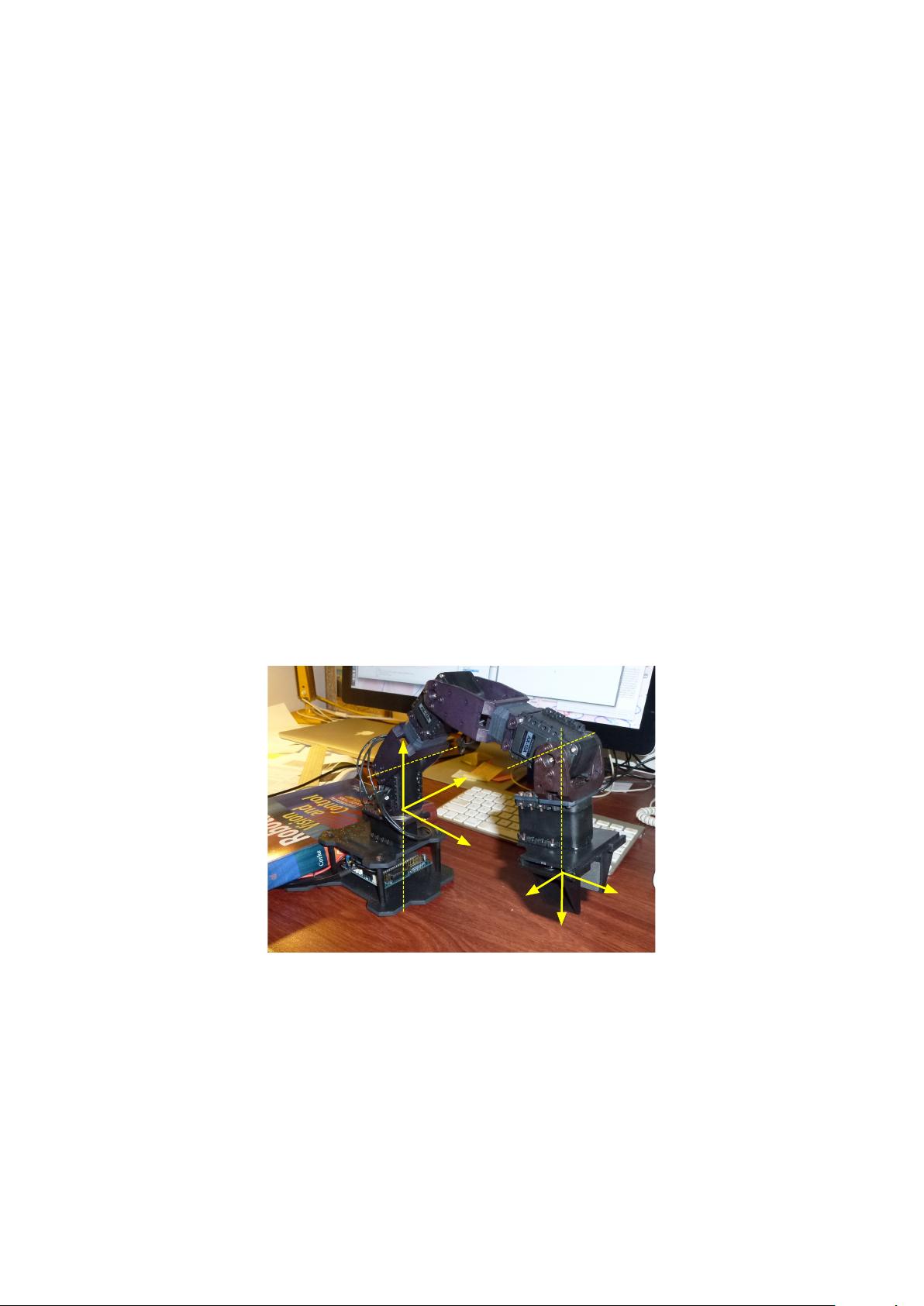

Many low-cost hobby class robots, such as shown in Figure 1 have only 4 joints

(degrees of freedom). This document describes how to determine inverse kinematics for

such a robot using the Robotics Toolbox[1] for MATL AB.

Underactuation complicates the process of finding an inverse kinematic solution, and

it frustrates those who are new to robotics — those who just want to run the code and

get an answer. For a robot with 6 joints it’s quite straightforward, but underactuation

requires some careful thought about the problem that you are trying to solve — you

can’t just blindly use the tools.

We will consider the problem in two parts. First the problem of moving the robot

tool to a particular position. Second, moving the tool to a particular position and tool

orientation.

z

t

y

t

x

t

x

0

y

0

z

0

Figure 1: The PhantomX robot sitting on my desk. The world frame {0} and the tool

frame {t} are shown. Note I’m using a book over the back feet to keep it from toppling

over.

1

资源评论

Elen005

- 粉丝: 39

- 资源: 36

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

前往需求广场,查看用户热搜

前往需求广场,查看用户热搜安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功